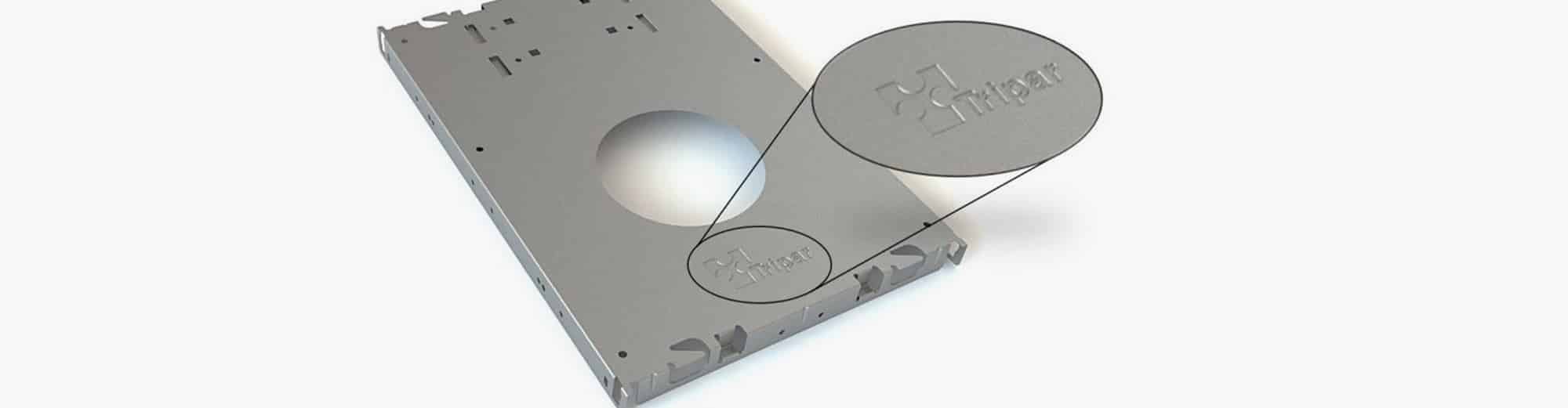

New Product Bulletin – Tripar Support System Kits

Tripar has a range of support systems including brackets and bar hanger components that are often purchased individually. Following customer feedback and always looking to enhance our offerings to the market, Tripar has developed a range of Kits to meet your support system needs. Each Kit is configured and packaged to the most commonly needed pairings. Please note custom kit pairing can be produced on request.

Discover our Kits

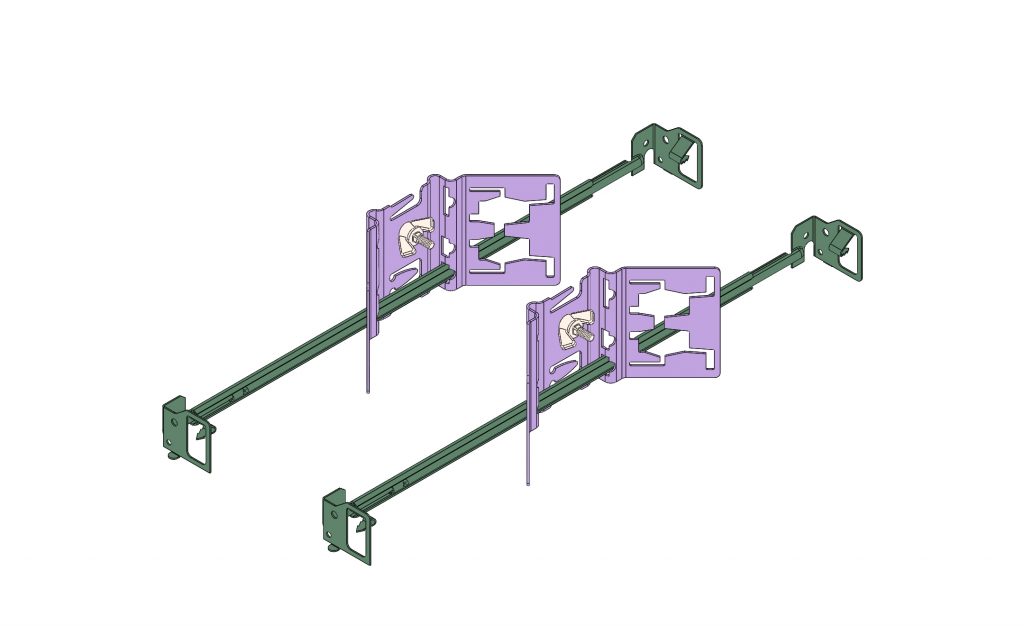

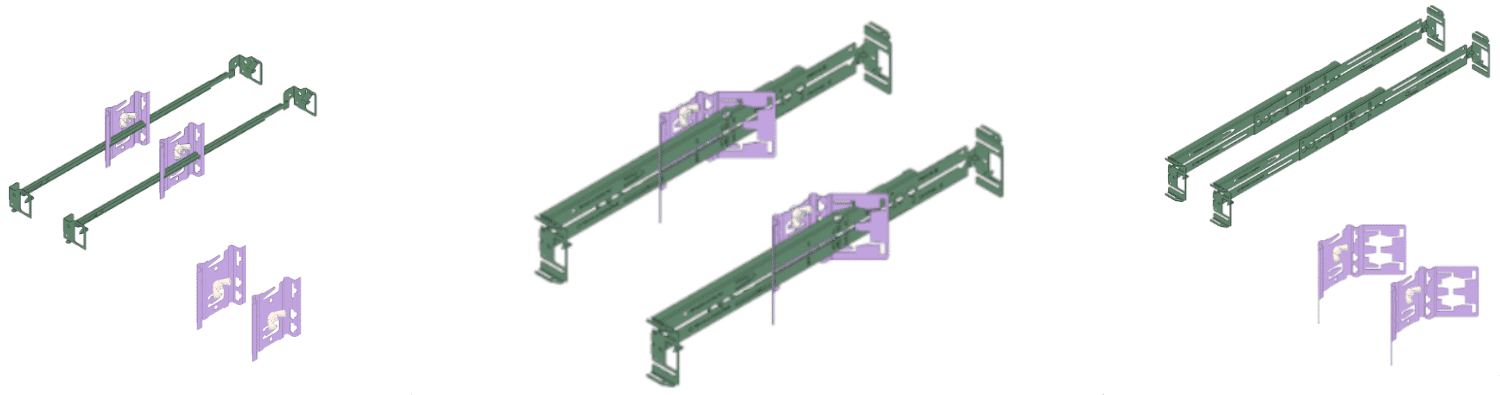

1254/1287K

Kit includes

- 2 x Butterfly Brackets (#1254)

- 2 x Bar Hanger sets (#1287)

- 2 x Carriage Bolts & Wing Nuts (10-24UNC)

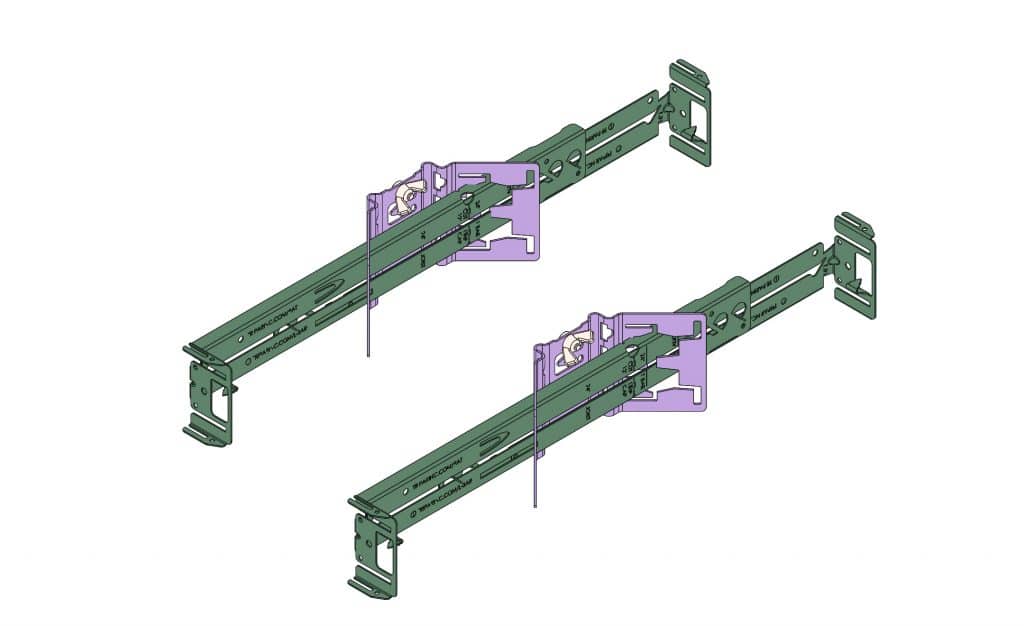

1254/1487K

Kit includes

- 2 x Butterfly Brackets (#1254)

- 4 x Commercial Bar Hanger (#1487)

- 2 x Carriage Bolts & Wing Nuts (10-24UNC)

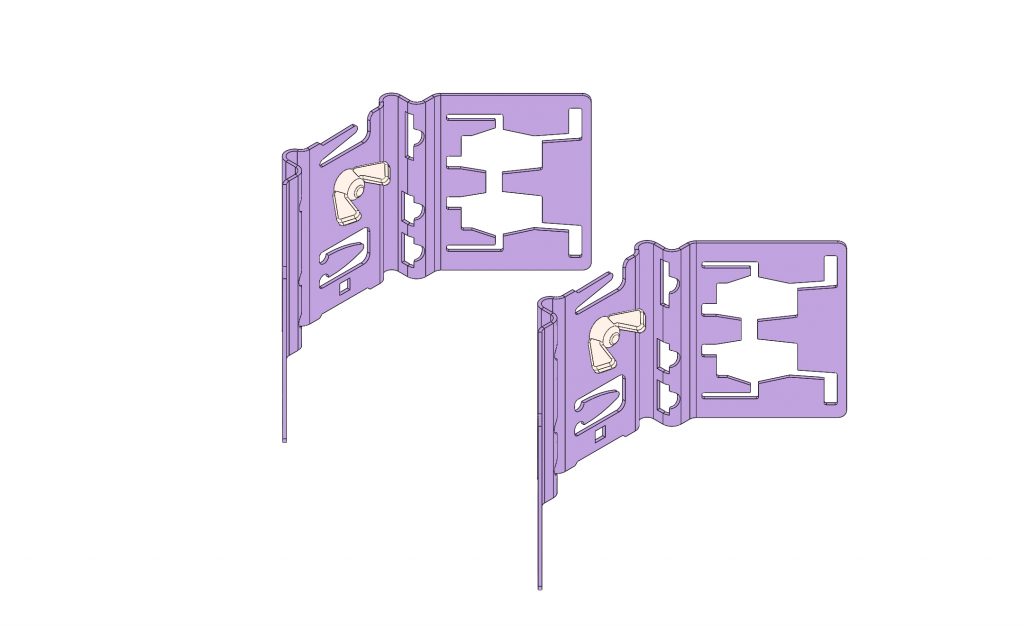

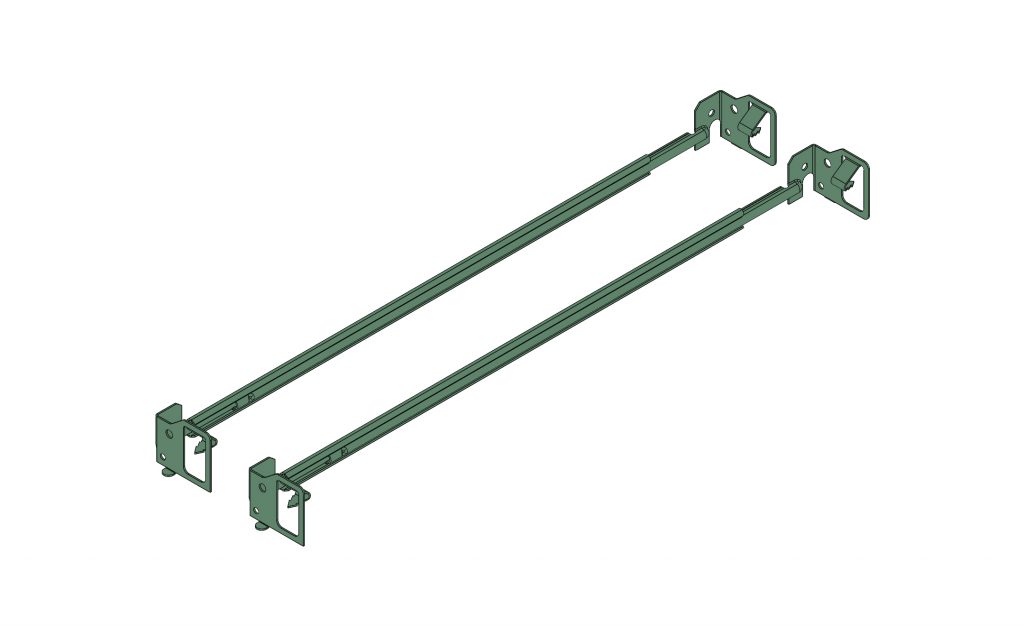

1254K

Kit includes

- 2 x Butterfly Brackets (#1254)

- 2 x Carriage Bolts & Wing Nuts (10-24UNC)

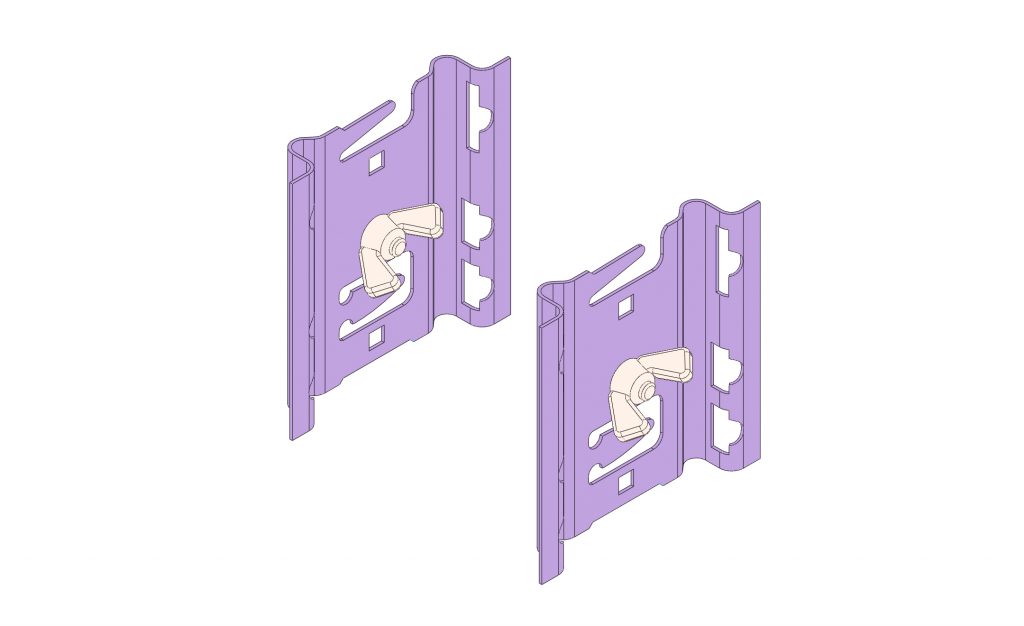

1054K

Kit includes

- 2 x Caterpillar Brackets (#1254)

- 2 x Carriage Bolts & Wing Nuts (10-24UNC)

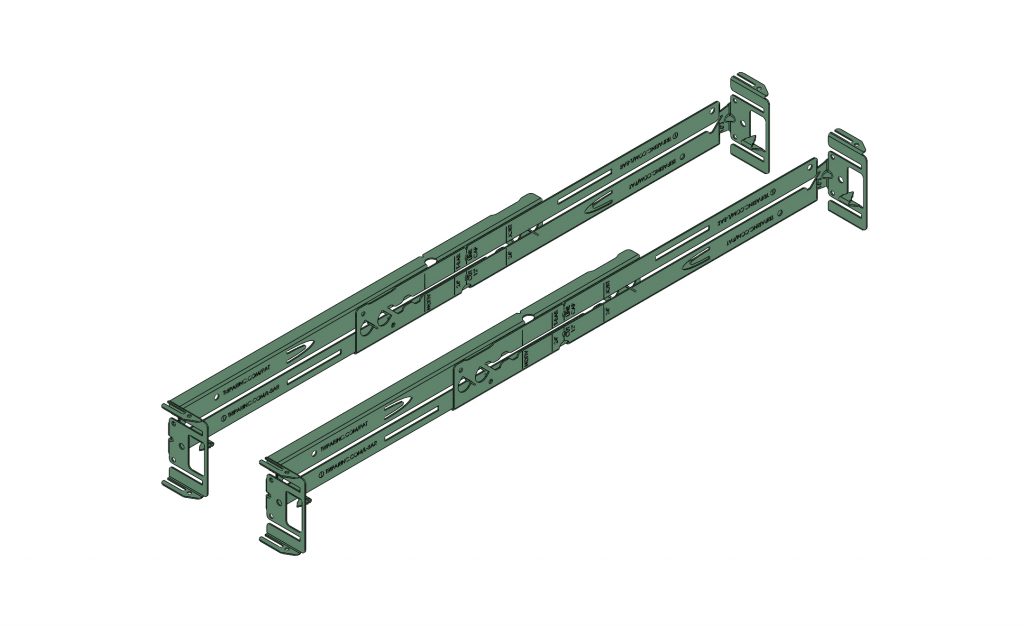

1487K

Kit includes

- 4 x Commercial Bar Hanger (#1487)

1287K

Kit includes

- 2 x Bar Hanger sets (#1287)

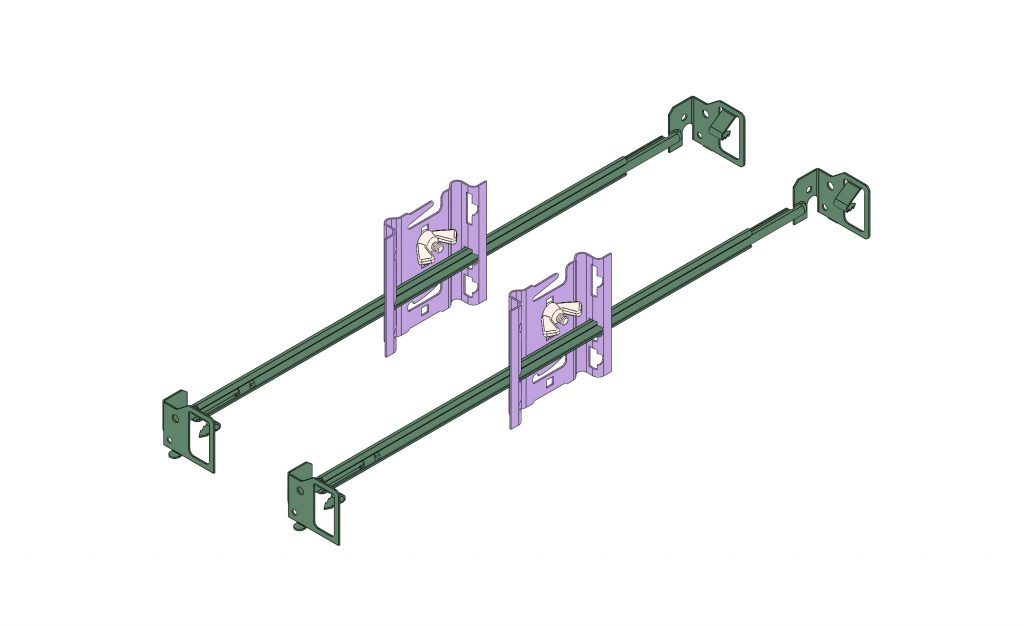

1054/1287K

Kit includes

- 2 x Caterpillar Brackets (#1054)

- 2 x Bar Hanger sets (#1287)

- 2 x Carriage Bolts & Wing Nuts (10-24UNC)

Benefits of these Kits include:

- OEM will have better inventory management.

- Easier transport of the light fixture with these components to the installation site.

- Easier installation onsite.

- Guarantee that the correct quantity of each component is provided.

To obtain more information about these products, or to request a custom kit to suit your particular requirements, please contact our Sales Team at Sales@TriparInc.com.

• Fully caulked corners with UL traceable caulking

• Fully caulked corners with UL traceable caulking