Overview

Clinch joining, or press-joining is a process used to join two pieces of sheet metal together without any fasteners. It is also known by the following brand names; Tog-L-Loc®, Rivclinch®, Tox®, and Pressotechnik. The process uses a small press and special tooling to locally and plastically form an interlock between two (or more) sheets.

Clinch joining, or press-joining is a process used to join two pieces of sheet metal together without any fasteners. It is also known by the following brand names; Tog-L-Loc®, Rivclinch®, Tox®, and Pressotechnik. The process uses a small press and special tooling to locally and plastically form an interlock between two (or more) sheets.

A graphical animation of the process can be found online, please click here to watch it.

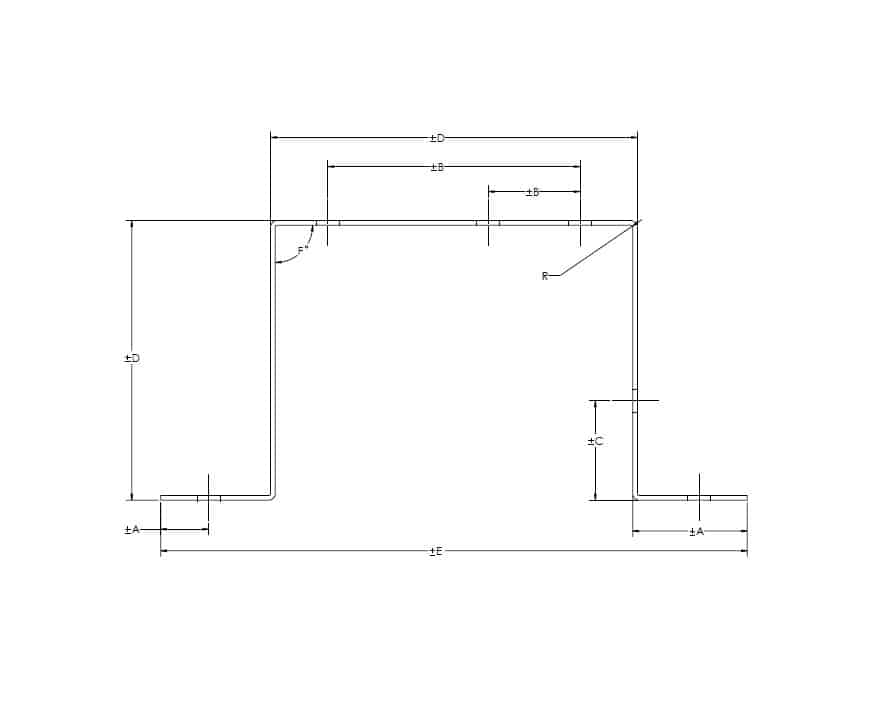

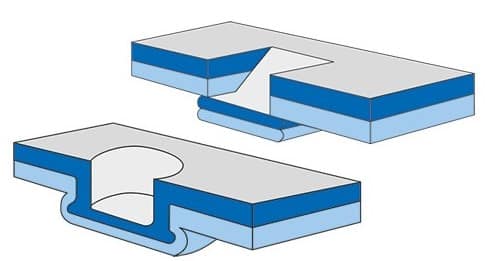

The process typically uses a solid male punch, and a split female die containing 3-4 quadrants (think of a drill chuck). The punch is forced into the two pieces of sheet metal to be joined. Since the punch and female die underneath both have corner radii, and sufficient clearance between the two for the combined sheet metal thickness, the metal does not tear. Instead, both pieces of sheet metal bulge and are pressed into the female die resting underneath the pieces.

In the case of a split female die, as the male or upper punch reaches a predetermined penetration, the female die quadrants expand, permitting the two pieces of sheet metal to bulge outward, creating something akin to a dovetail joint, except in this case circular. Upon punch retraction, the split female die quadrants also retract inward as the new interlocked joint assembly is removed.

Typical sizes for 16 GA sheet or under, are 3/16” – 3/8” diameter x 1/16” – 1/8” depression/projection.

Advantages:

- Low cycle time; < 1 second per joint;

- Reduced cost and weight: no additional elements are required such as screws, rivets or adhesives;

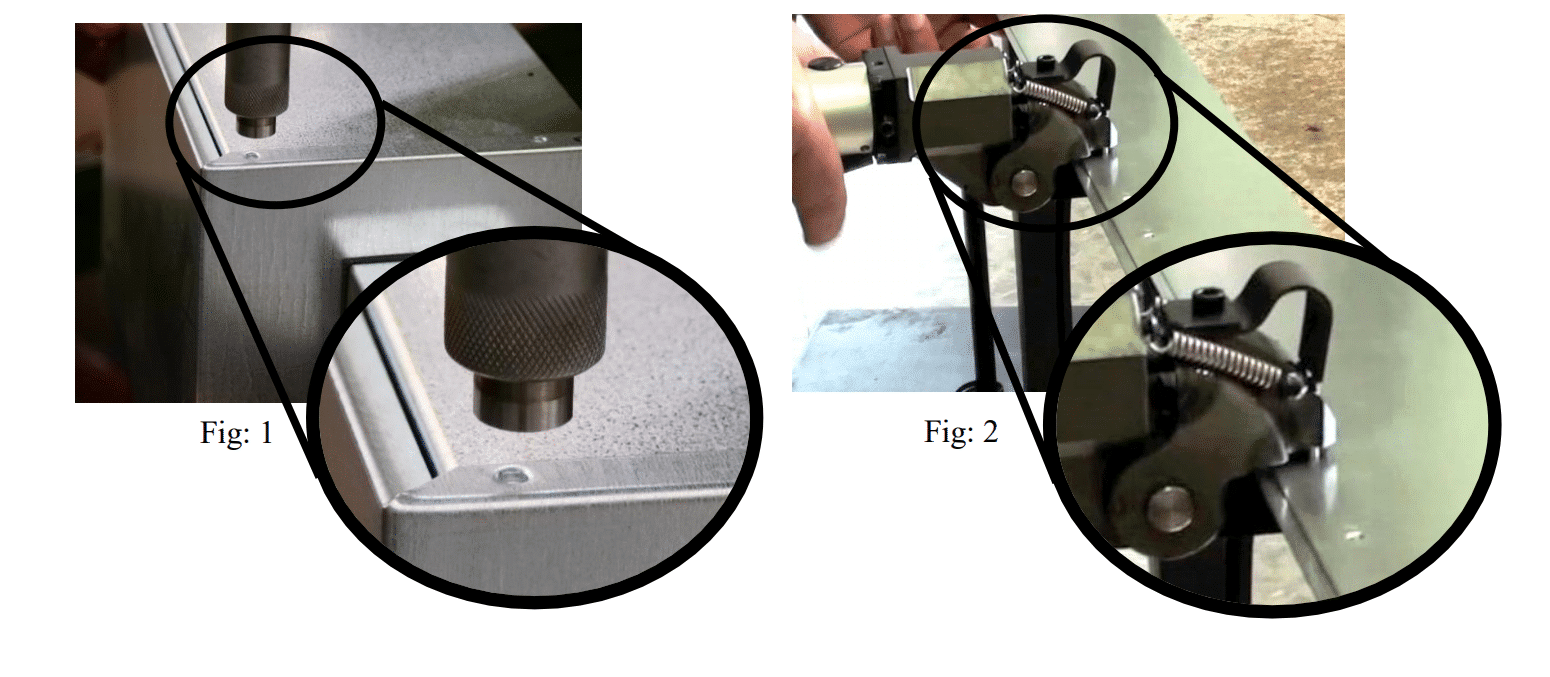

- Reduced machine cost; typically, a small mechanical or hydraulic press is all that is required (See Fig. 1);

- For larger assemblies that might be difficult to manipulate or orient to the press, hand held (pneumatic or hydraulic machines) can be used (See Fig. 2);

- No pre-drilled or punch holes are required (as would be required for riveting);

- Unlike spot welding, can be used on prepainted sheet metal, and without damaging the painted surface;

- Excellent for joining aluminum, which can be difficult to spot weld;

- Can join different or mixed metals, e.g. steel to aluminum;

- Can be easily automated and does not require skilled workers;

- Eco-friendly: Does not require pretreatments with solvents, acids, and other harmful liquids;

- The mechanical strength of the metal material near the joint is generally increased due to both the mechanical lock and work-hardening;

- Cleanliness: The process does not produce flashes or fumes;

- Flexibility: The same tools can be employed for a wide series of materials.

Disadvantages:

- There is a small depression on one side assembled sheets, and a protrusion on the other;

- Visual; because the process leaves a small depression on one side, and a similar projection on the other, it is typically not used where a cosmetic appearance is required;

- Because there are no pre-drilled or punched holes that help with locating or positioning, jigs may be required to hold workpieces in position before being joined.

Reviewing joining options with your metal fabricator early on in the design process offers the best chance at finding the optical method to meet your requirements.

For more information please contact TriparTech@TriparInc.com.