New Product Bulletin – Recessed Trim Spring*, Trims & Gimbals

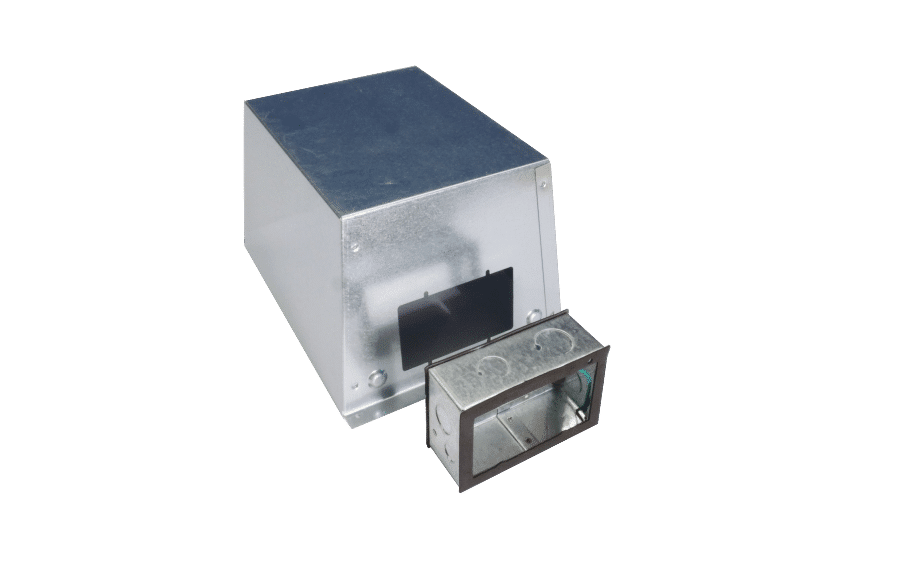

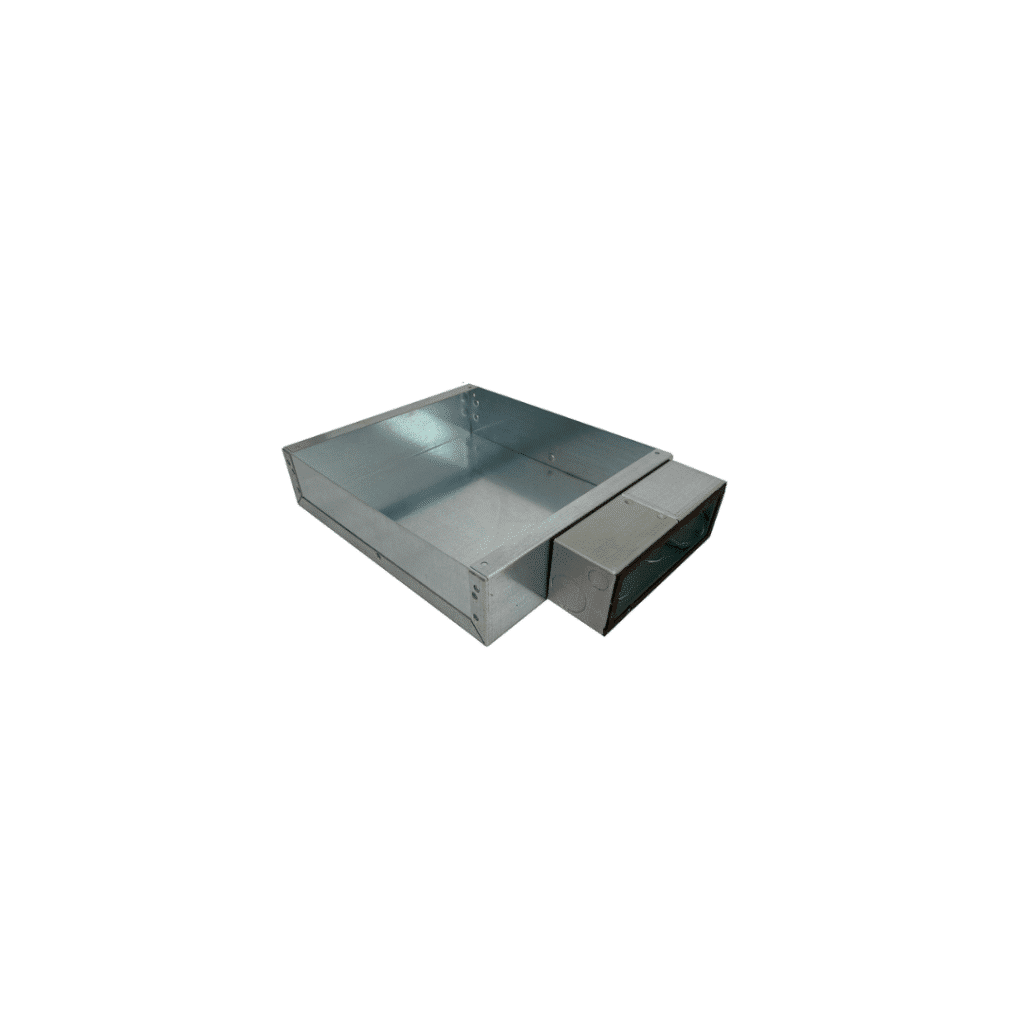

We are pleased to offer a new series of springs for securing trim/gimbal assemblies (for MR16, GU10, PAR 20, 30, etc.) to recessed housings, as well as a new series of trims.

Depending how these curved springs are mounted to the trim (curved in or out), they secure a variety of trim assemblies to fit in an equally wide variety of housing sizes. The top edges of the springs have gentle curves, permitting the springs to be self-compressed as the trim is pushed into the housing. Unintentional removal however is not so easy. Mounted with the curve facing inward, projecting teeth bite into the inside surface of the housing, providing excellent resistance to movement from vibration. When mounted with the curve facing outward, similar retention is achieved by way of sharp corners biting into the inside surface of the housing.

Assembling these springs is incidental, as the same two rivets used to secure the gimbal to the inside of the trim are used to secure the springs to the outside.

Flush installation of housings to the ceiling is no longer critical. Because the spring ends bind at any position within the housing, the trim can always be pushed flush to the ceiling – even if the housing is installed slightly recessed or even canted.

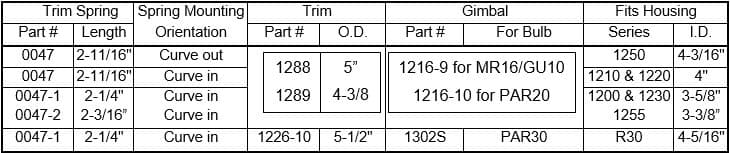

The compatibility chart below shows how these springs are compatible with a wide variety of trims and housings, offering solutions to almost any application.

All trims contain a slight bevel around the periphery, ensuring intimate contact with the ceiling, but otherwise offering a near flush mount.

Both springs are made in a progressive die, and all trims, gimbals and housings are made in dedicated tooling for the most competitive pricing.

*U.S. Pat. 6,719,438.

To obtain more information please contact our Sales Team at Sales@TriparInc.com.