About Tripar Inc.

75+ years delighting customers. How can we help?

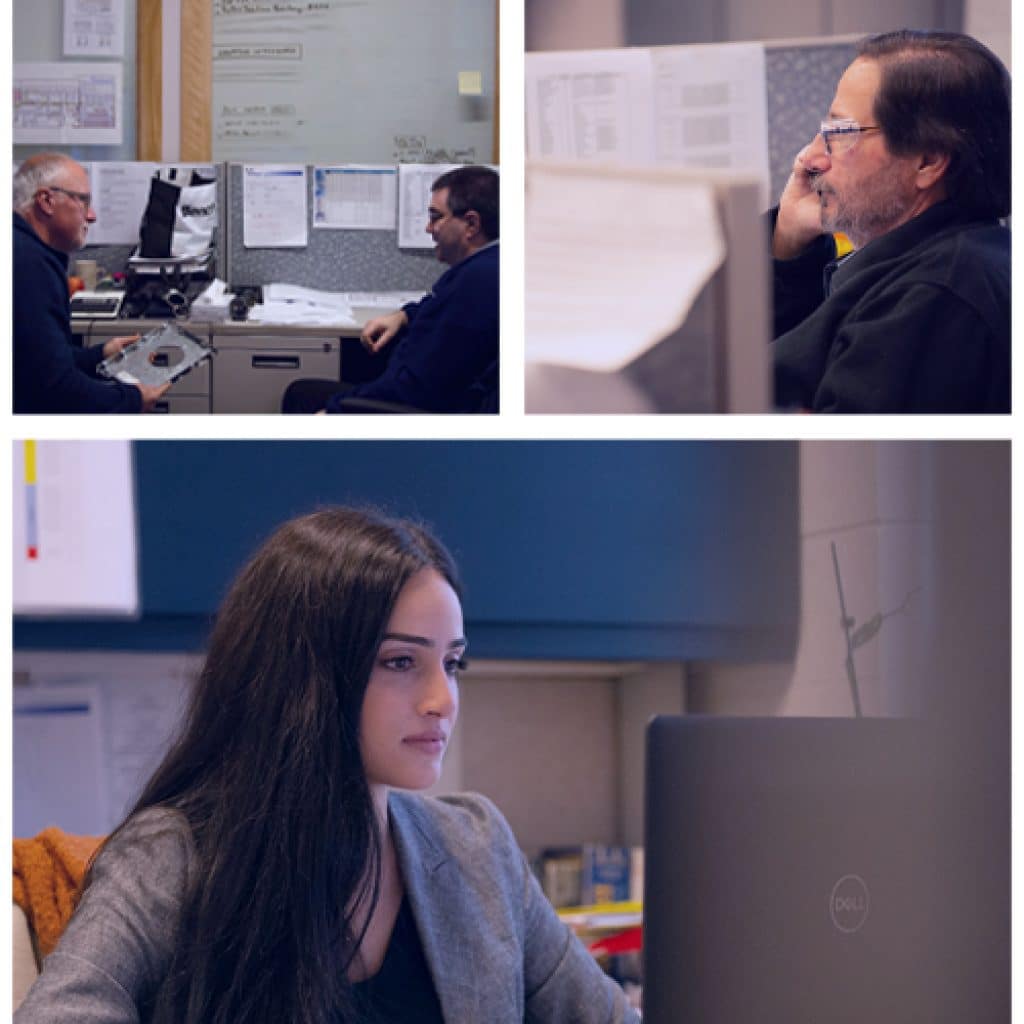

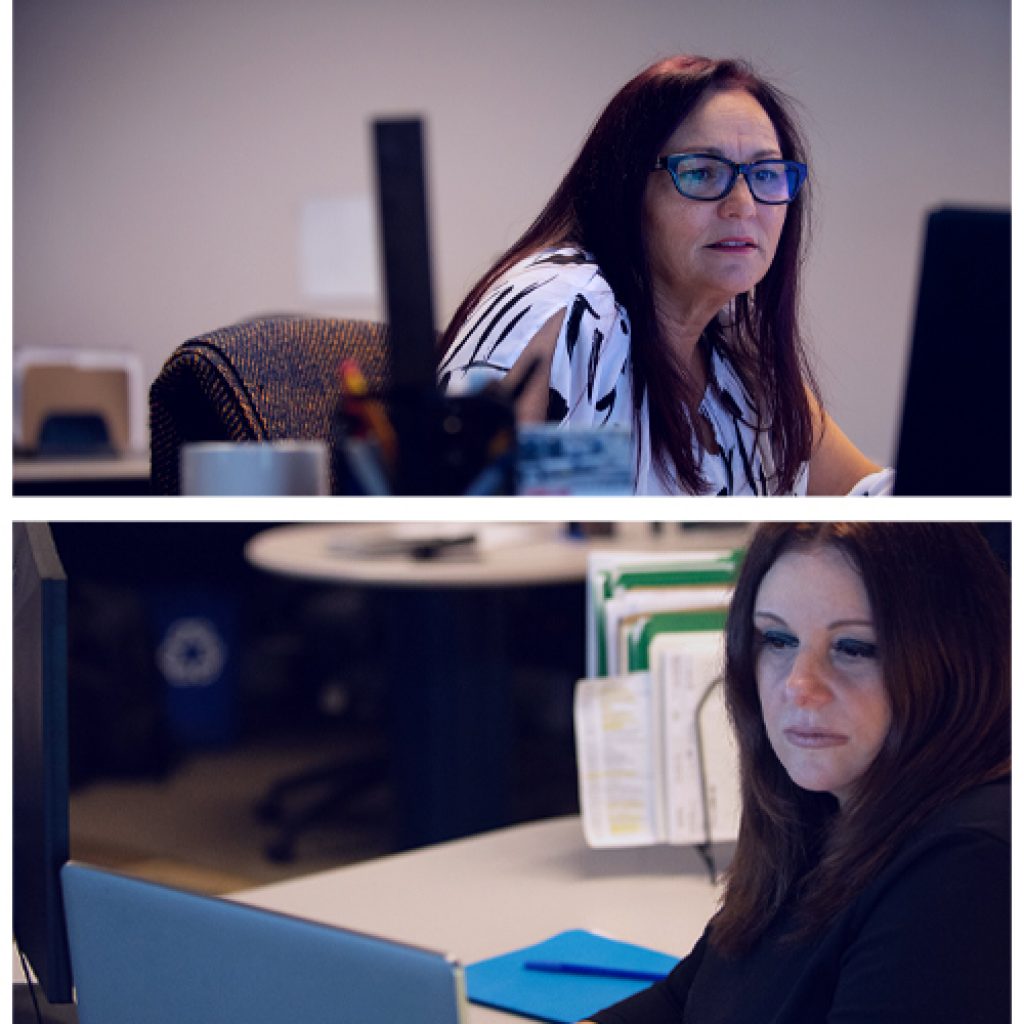

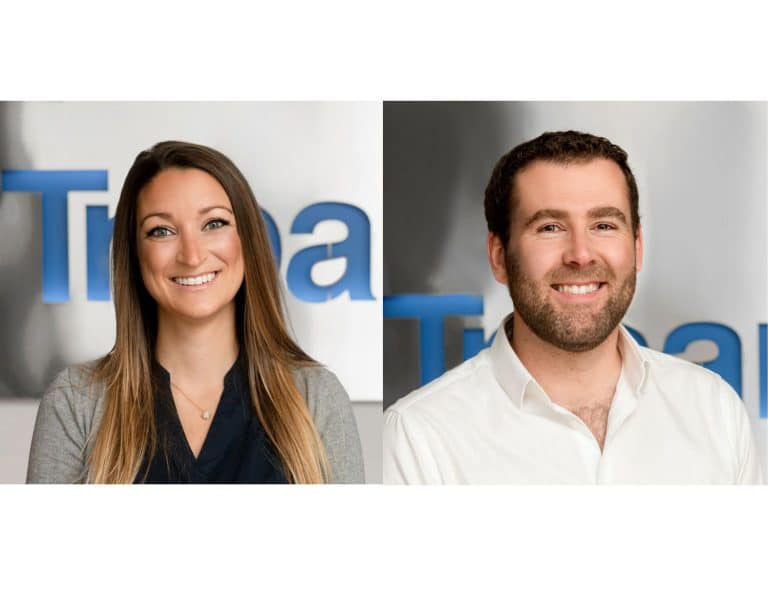

A family business that cares

Tripar was founded in Montreal in 1949 by Ben Sevack and remains a family-run company. Tripar went to its 2nd generation when Ben’s son Lloyd, P.Eng, (on the left) joined in 2001. Lloyd’s daughter Lauren (on the right) joined the company in 2013, bringing three generations into one. Ben, our founder (the gentleman in the middle) is now over 100 years old.

The 30-Second Tripar Story

Over the last 70+ years, Tripar went from a small metal stamping shop in Montreal to becoming the “gold standard” in the OEM lighting industry with a 67,500 sq.ft. facility; offering you a complete range of metal stamping and CNC metal fabrication capabilities to suit your needs.

Our success is in big part because we go above and beyond for clients. Not only do we invest in the latest technologies, we offer clients the highest quality, engineering & design assistance, manufacturing and delivery, at great prices and lead times so OEMs can thrive in their markets.

We aim to be the easiest company you’ll ever work with — while providing you the most innovative products at the lowest possible cost.

Many clients have worked with us for 10 to 30 years

We work multiple industries: lighting, HVAC, warehouse racking, consumer goods, aerospace, renewable energy, etc.

See what the fuss is all about. Our President Lloyd Sevack speaks.

Please click here to watch more Tripar’s videos on our YouTube channel.

Mission

To help clients convert their metal stamping & fabrication problems and needs into innovative solutions; with quality, precision, and cost-effectiveness in mind.

Vision

To partner with every client for life and be a strategic partner.

We continuously invest in R&D, product development and our manufacturing capabilities to create new & strategic opportunities, enabling us to strengthen our reputation as being as one of the most skilled and respected manufacturers exploiting the duality of metal stamping and fabrication technologies.

Tripar is the largest stamped & fabricated metal components supplier for the OEM lighting industry. We strive to do the same for other industries through proven principles of collaboration.

The Tripar Advantage

What sets us Apart

1. Strategy

We continuously strengthen our R&D, product development and manufacturing capabilities to create new & strategic opportunities.

2. Collaborative Approach

Exploiting our proven principles of collaborating with customers to solve their problems with innovative solutions, quickly, and cost-effectively.

3. Design for Manufacturability

When you request a quote, our Estimating and Design Engineering team may question certain aspects of your design. Why do we do this? To simplify your design using DFM principles to save you money.

4. Hybrid Manufacturing

We're on one of few manufacturers who can offer both metal stamping and CNC fabrication. We scale to your business needs, offering you a range of options and multiple cost-effective solutions.

5. Unbeatable Engineering

In addition to DFM, we offer pre-production assistance of various levels, including 3D Modelling, Technical drawing creation and Prototyping.

6. Risk Mitigation

We won't arbitrarily quote and tell you of issues once you place an order. We will address all product & design concerns in the quoting phase. So you never have to worry about hidden costs or extra rework fees.

Our OEM clients appreciate quality, speed, reliability, and how to best use metal components in their products

Also, those in the lighting industry also appreciate our huge component line, plus the fact that we know, understand, and respect applicable UL standards. All appreciate that we quickly react to requests such as rush orders and design modifications. Through lean manufacturing, we pass on our savings to clients.

Turn Your Ideas Into Production

Historical Timeline

Tripar is Founded

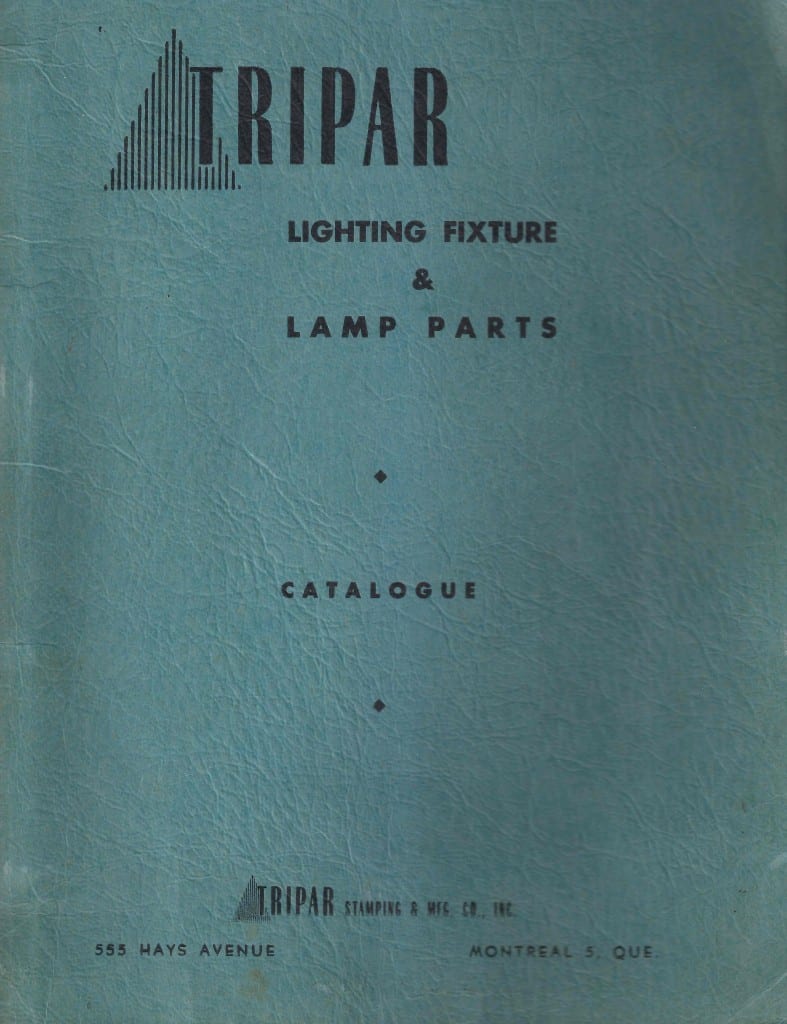

Tripar’s First Catalog

Tripar's 10th Anniversary

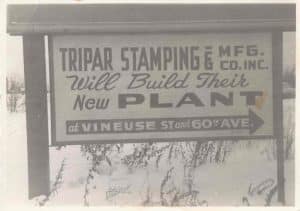

Construction of Tripar’s new Factory

1st Expansion of the Factory

20th Anniversary – 2nd Expansion

Tripar and the CFIB

3rd Expansion of Factory

Ben and Robert Bourassa

30th Anniversary – 4th Expansion

Montreal Board of Trade Award

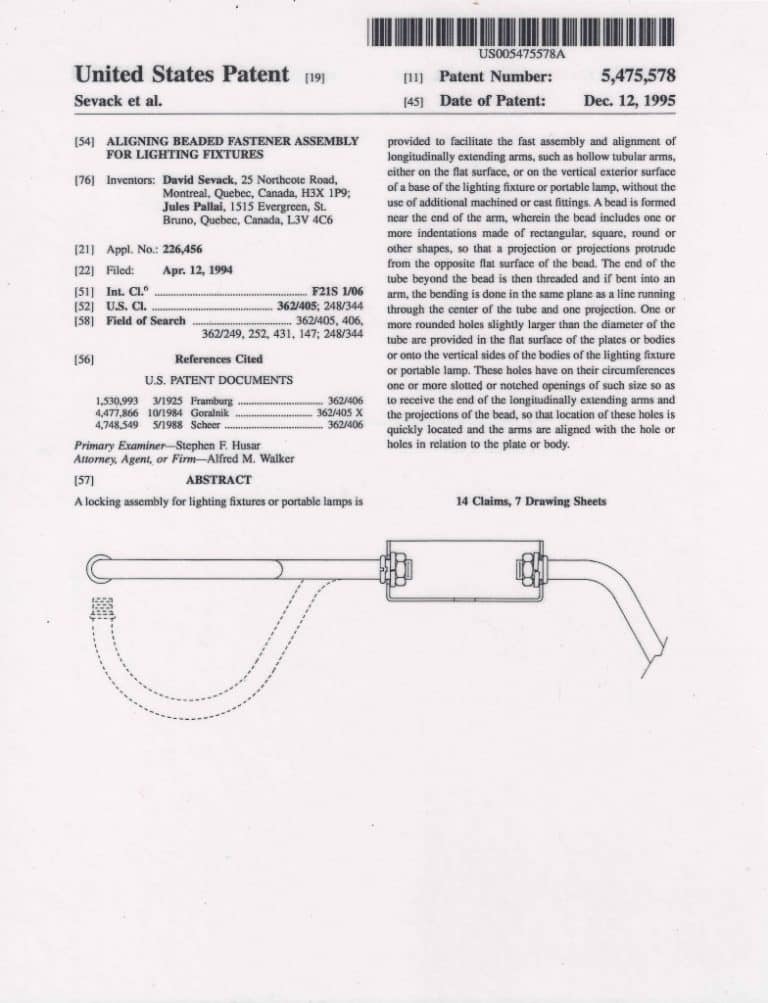

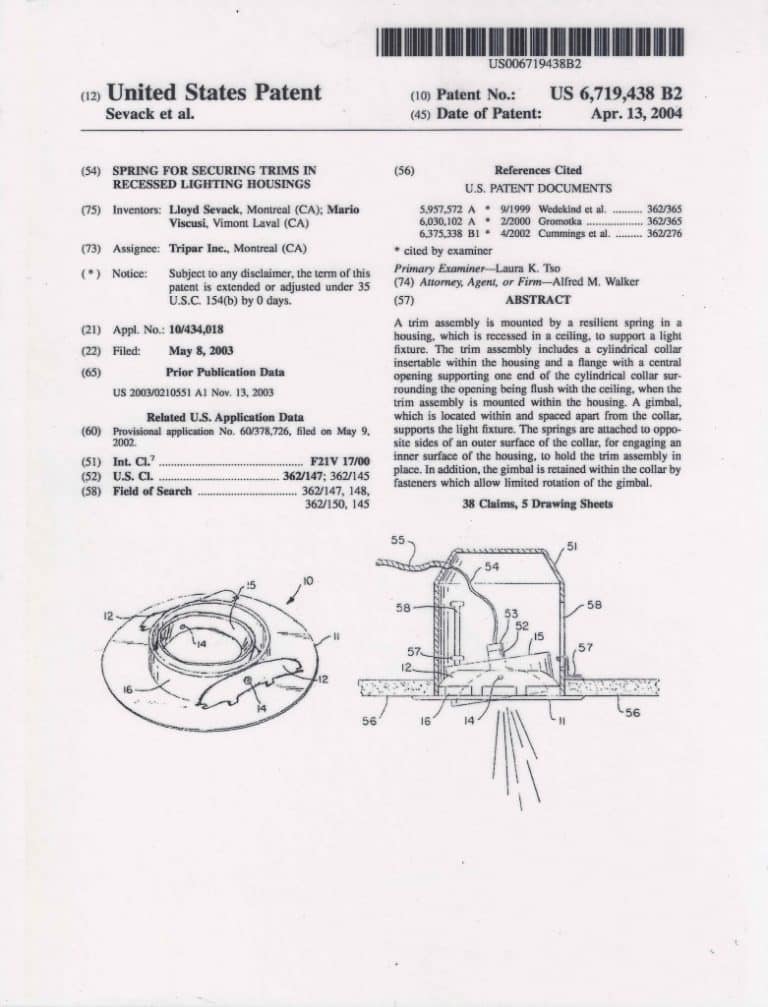

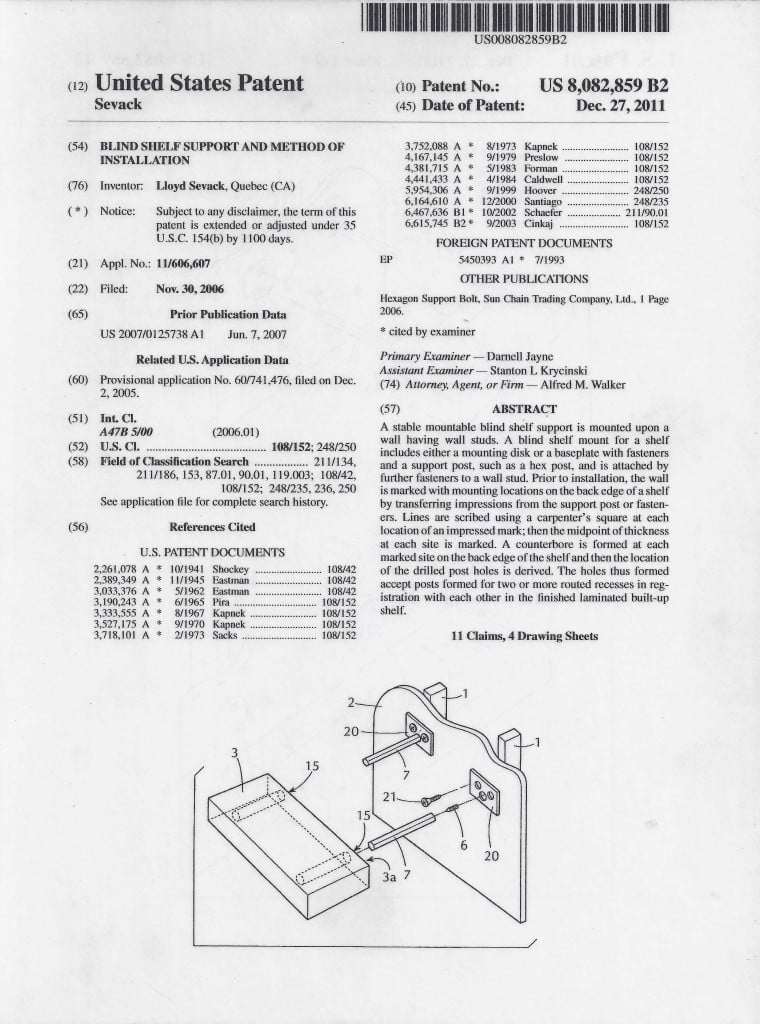

1st US Patent

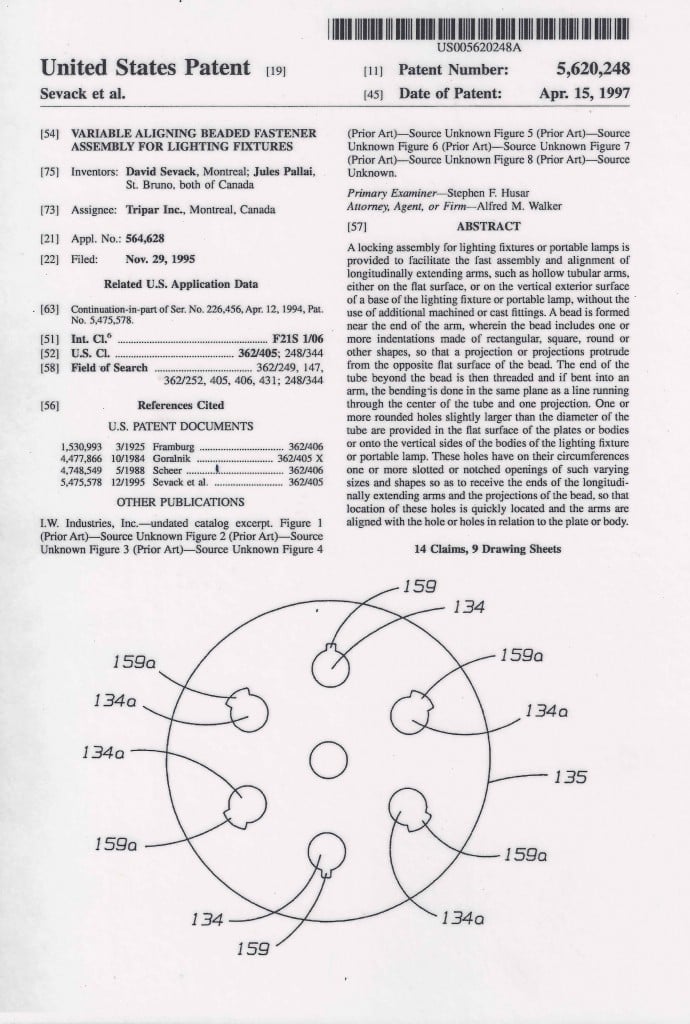

2nd US Patent

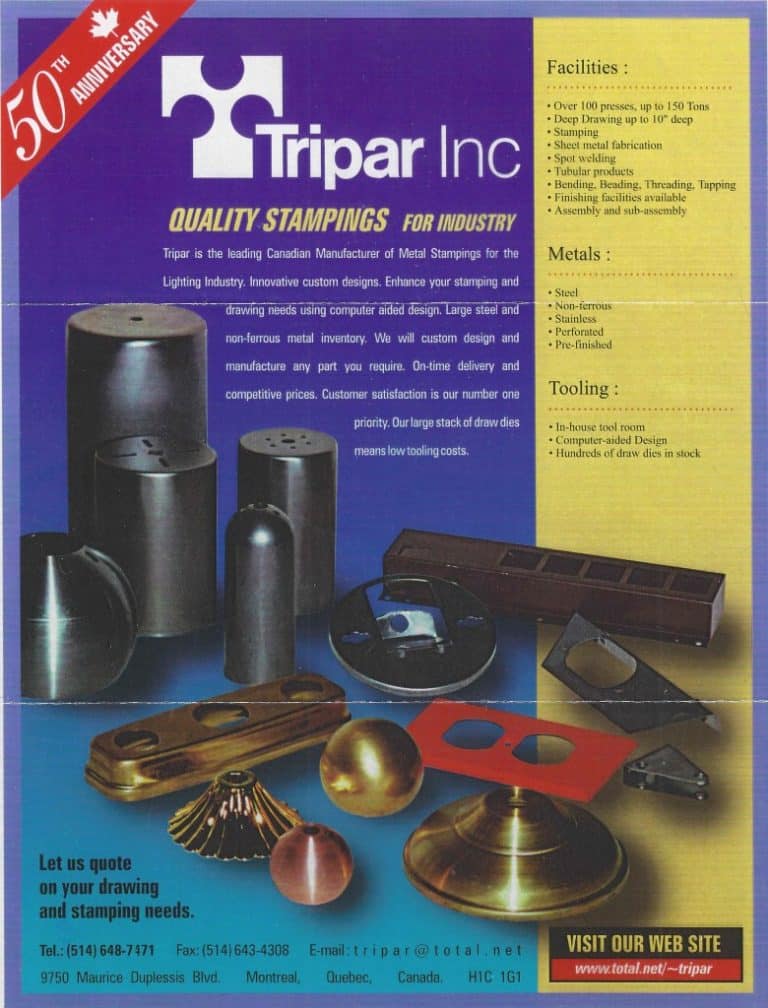

50th Anniversary

Two Generations of the Sevack Family

55th Anniversary

CFIB Recognition

Innovation Prize from CSST (Quebec Safety Board)

Prix Estim – Best Manufacturer

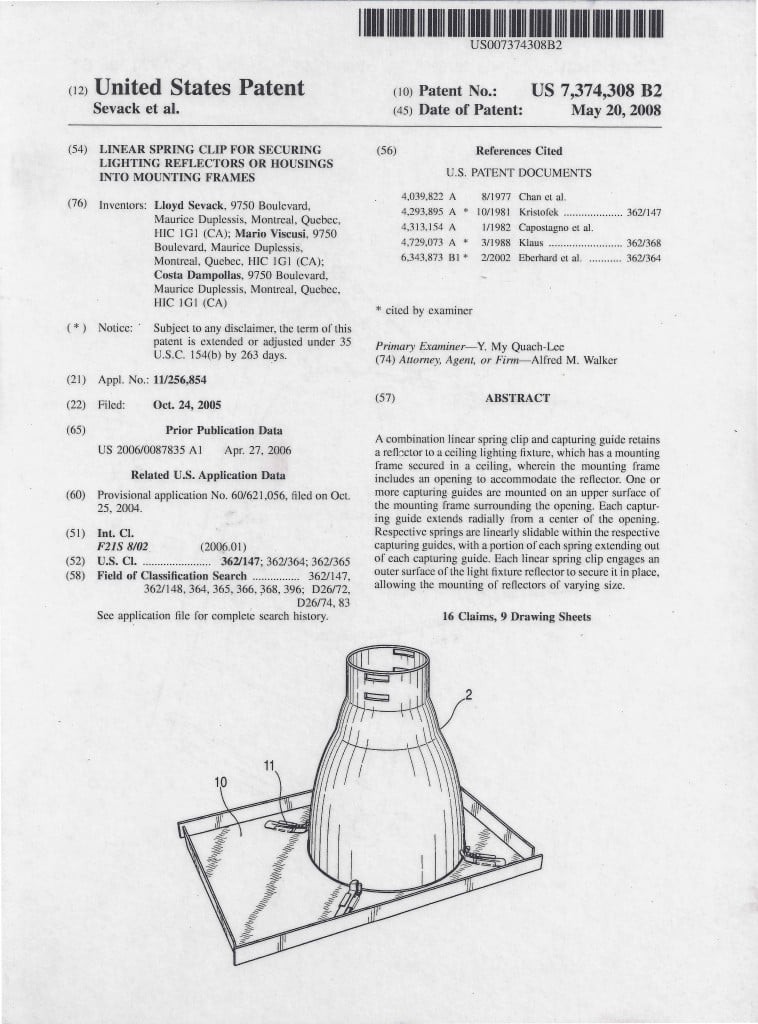

4th US Patent Estim – Best Manufacturer

60th Anniversary

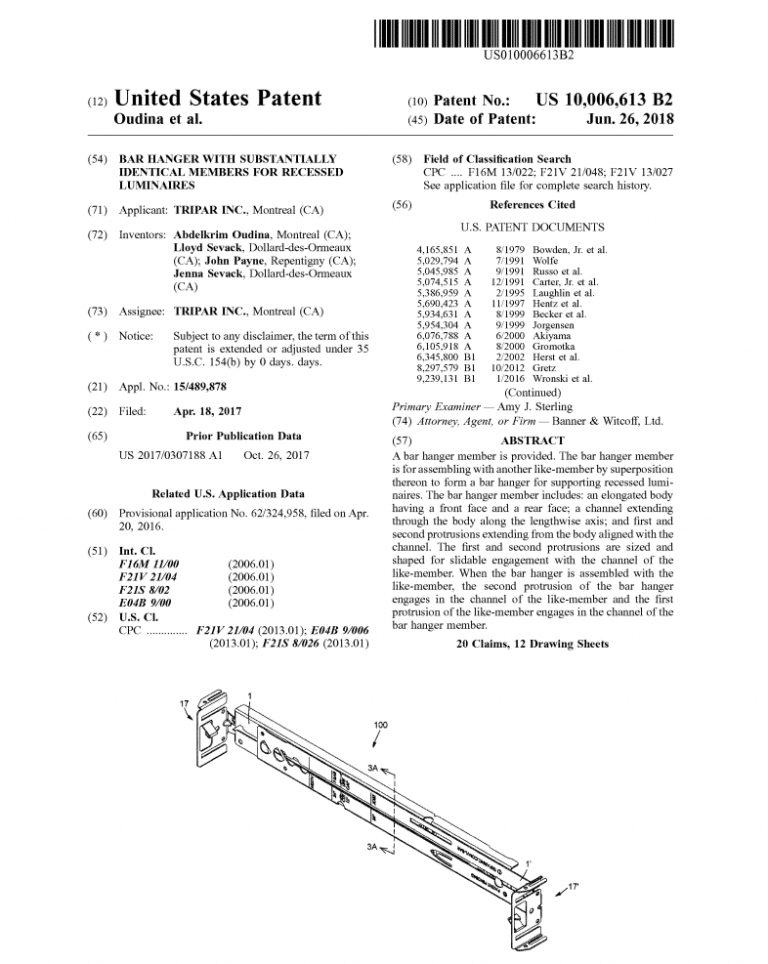

5th US Patent

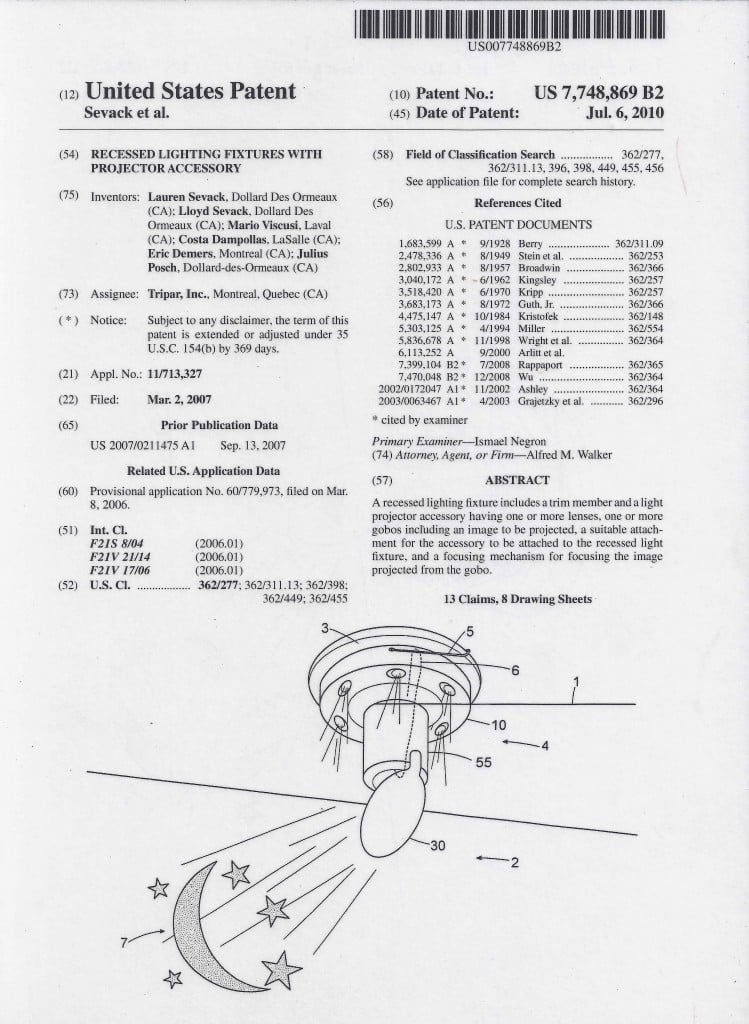

6th US Patent

Three Generations of the Sevack Family

65th Anniversary

CNESST Safety Award

‘Prix Estim’ Best Exporter Award

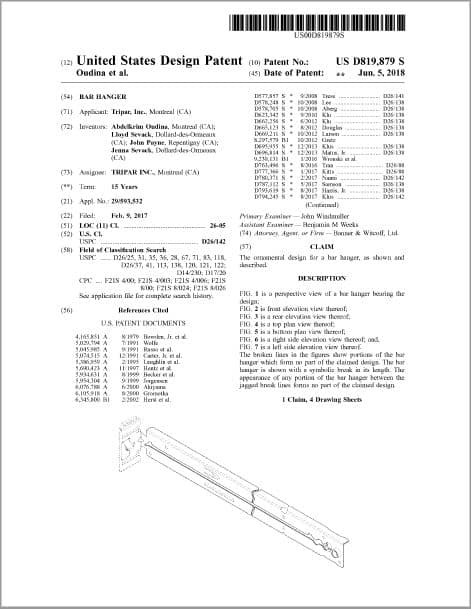

7th US Patent

CNC Laser/Punch Combo

8th US Patent

Tripar’s Open House

70th Anniversary

20,000,000th #1287 Sold

70th Anniversary XMAS Party

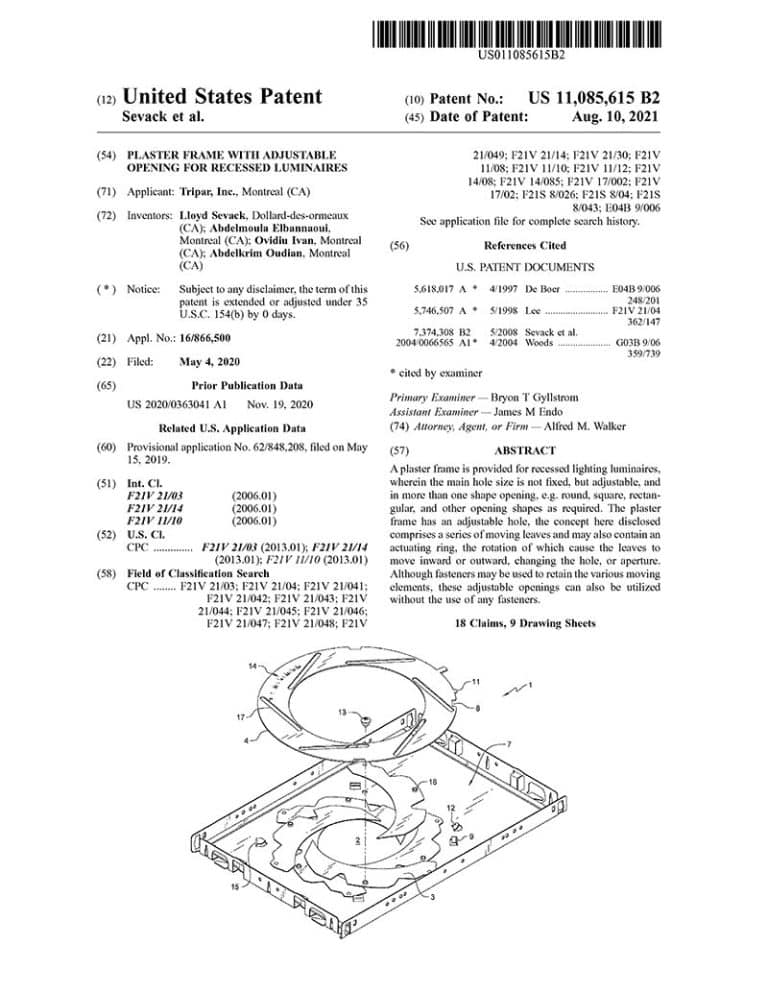

9th US Patent

Aida 220 Ton Press

Trumph Trupunch 1000s

Appointment of CAO & COO

Founder turns 100! years old

25,000,000th #1287 Sold

Amada HG 1003