Tripar Engineering Services

Improve your sheet metal designs and products

Engineering services

Engineering is the backbone of Tripar. We support you through all your sheet metal fabrication needs: Design for Manufacturability (DFM), 3D CAD modelling, technical drawing creation, prototyping and sampling, and more.

We produce your sheet metal products and components according to OEM standards and industry specifications (ie. ISO, UL, ASME, etc). We serve 10+ industries and 350+ OEM partners.

Design for manufacturability (DFM) services

Are you overpaying on parts? Tripar will review and optimize your sheet metal component designs to reduce unit costs. Techniques include modifying the design to reduce the number of manufacturing operations required, make the part or tooling required more robust, improve production speed, using pre-existing (or modified) Tripar tooling (we have 1600+ dies and 300+ CNC punches), reducing material costs (thinner material, different spec, using Tripar stocked material) and more.

*Much of this is explained in the TriparTech publications: DFM Part I & DFM Part II

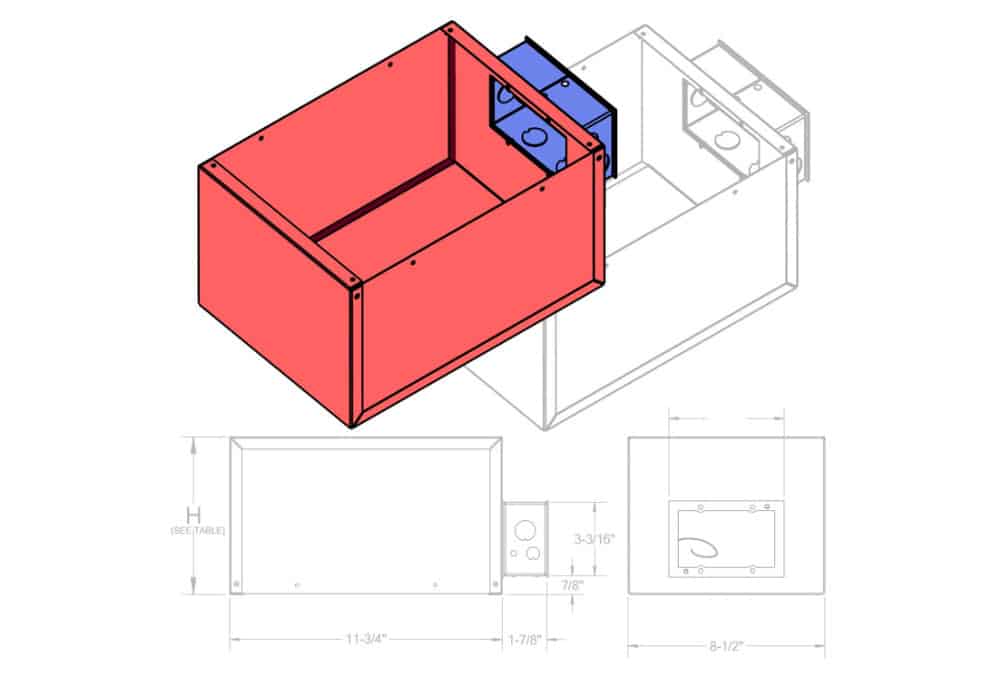

3D CAD modeling services

Need design help? We can create 3D or solids models of your components and flat development (if applicable) that is perfectly DFM'ed, unbranded drawings (Solidworks and PDF) and offer various CAD file formats (e.g. DXF) - for you to keep. It will be sent securely in a zip folder to the client.

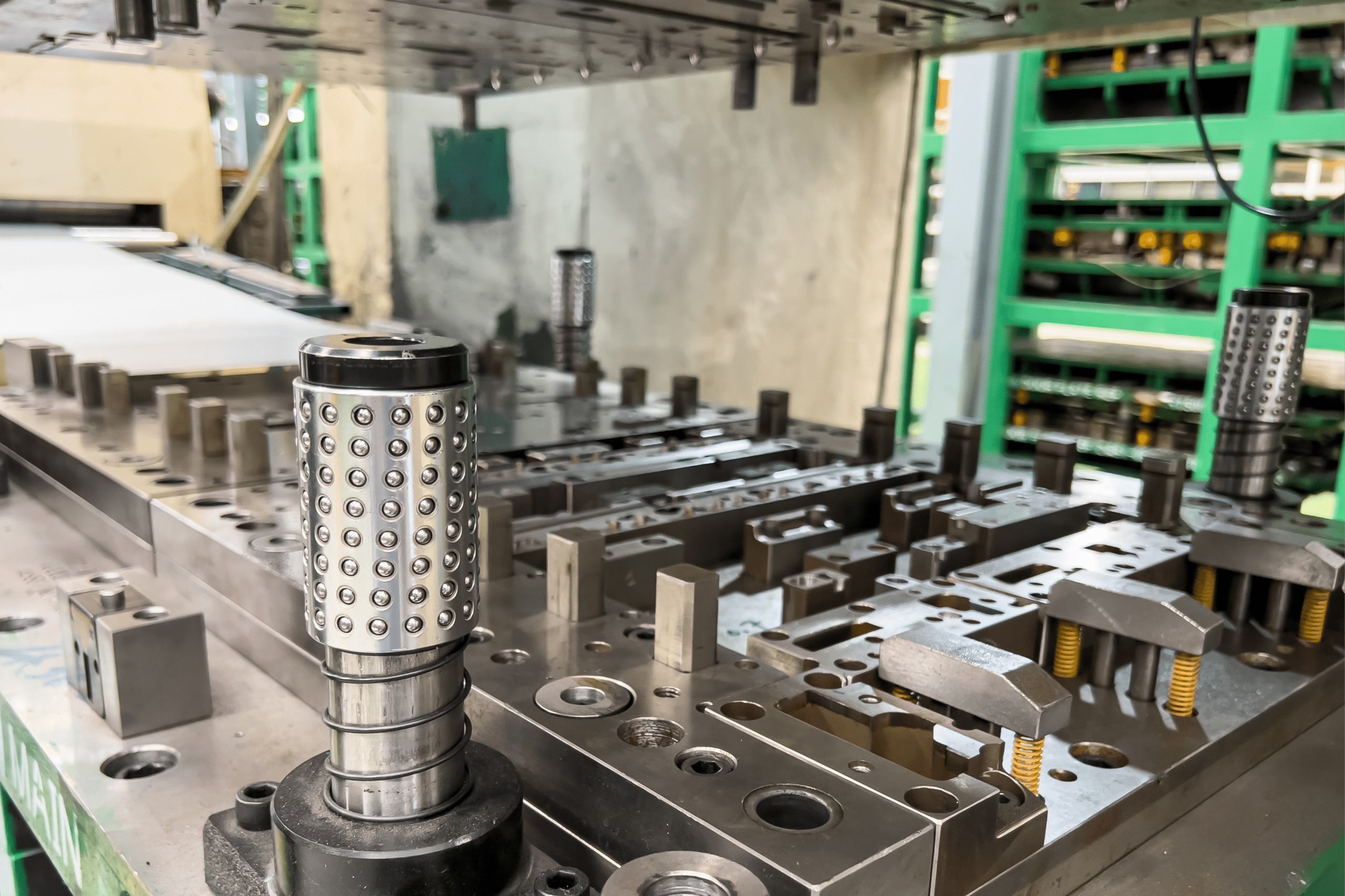

Metal stamping & toolroom designs

Got complex or high volume parts? For metal stamped parts, our expert in-house toolroom does die design, die building, first-off samples (PPAP) right into production. Having a toolroom permits us to sharpen, repair and modify dies in-house for much faster lead times and production.

Prototyping & samples

For CNC fabricated parts, Tripar can produce 5 samples of each component. Stamped samples can also be manufactured, depending on the die/tooling requirements. For pricing, please contact your customer service rep or sales@triparInc.com