Why Metal Stamping?

Metal stamping saves you a lot of money. There's no question about it. So when annual quantities or complexity of a metal part justifies it, Tripar offers a complete range of metal stamping solutions for all kinds of businesses.

Now, if we can fabricate your part by modifying one of our 1600+ "open-tooled" dies; you can slash your price by 2X to 3X over CNC metal fabrication (and at a fraction of what a new die costs!) That's the value of working with a company who values relationships and cares about your personal success.

Metal Stamping Services

Tripar offers metal stamping services for the OEM lighting, HVAC, consumer goods, renewable energy, warehousing, aerospace, and more. We’re one of the rare few companies that offers “hybrid manufacturing”: metal stamping or CNC fabrication or a combination of both (basically whatever saves you the most money!) We partner with OEMs to provide the most innovative cost-effective products.

Although CNC fabrication is great, it has its limitations too. Many OEMs don’t realize the benefits of metal stamping in terms of cost savings, speed and quality. Having the right hybrid manufacturing partner is an asset for your business and production.

Many clients have worked with us for 10 to 30 years. Why? Because we go above and beyond for every client.

Not sure if metal stamping is right for you? Get in touch and we’ll let you know in minutes.

Our Metal Stamping Capabilities

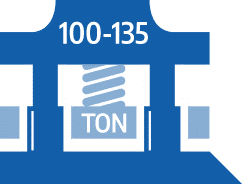

Over 100 quality metal presses

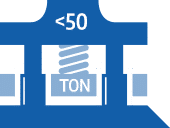

An expert in-house toolroom

- 1,600+ existing “open tooled” dies (that you can use)

- An internal department that works for you 24/7

- Customer-owned dies: we will store, maintain and repair your dies free of charge as our AAA service to you ($7500 Yearly Value - FREE)

- Wire EDM

- CNC milling

- Range of lathes, surface grinders, and other machine tools

- Heat treating too

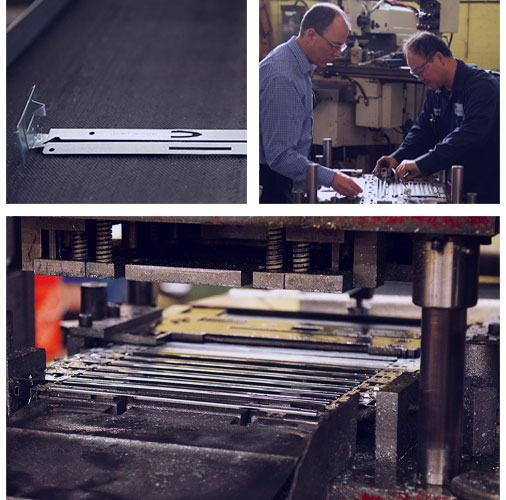

Progressive Stamping

From 2 to 10 station dies

Drawing &

Deep Drawing

Design & Quality You Can Trust

When quality, price and on-time delivery matters, clients call on Tripar

Design for Manufacturability

Not every drawing or CAD model sent by the client is manufacturable. If this happens, we’ll collaborate with you to ensure its manufacturability. Some fabricators won’t tell you and expect you to figure it out. Not us! We’ll let you know during the quoting phase of any potential issues so there’s no hidden surprises.

Send us your concepts and we’ll offer innovative solutions to save on your fabrication costs.

Quality Control

At Tripar, we put ourselves in your shoes so that dealing with us is is easy and pain-free. Our quality control program is built on the CSA Standard CAN3-Z299.4-85. So if any issue arises, it’s resolved quickly and a full report is shared with you (and how we’ll fix it so it doesn’t happen again.) We rarely get issues but they happen.