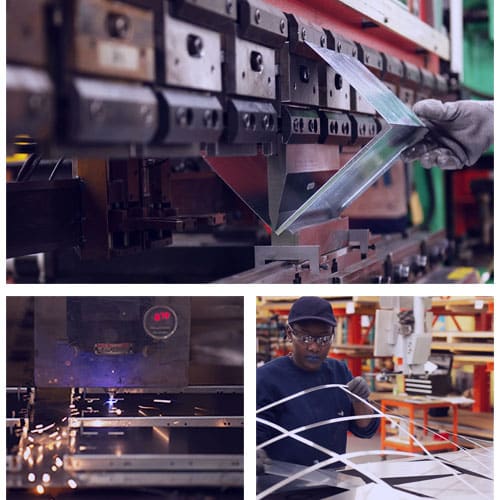

Metal Fabrication Services

We offer custom CNC metal fabrication services for all kinds of OEM products. We offer rapid prototyping and up to 20,000+ parts. Your CNC metal components will be delivered to you on-time and on-budget – with quality, precision, and efficiency in mind.

Our CNC Metal Fabrication Equipment

Tripar has a full range of CNC fabrication equipment to meet your metal fabrication needs.

CNC Laser / Punch Press Combo Machine

Trumpf Trumatic 1000

- Laser and Punch in operation

- Cuts to 10 gauge thickness material

- Galvanized & Cold-Rolled Steel, Stainless, Aluminum, & Pre-Painted or Pre-plated Steels

Punch Press Machine

3 x Trumpf TruPunch 1000

- Punching and forming on one machine.

- Cuts to 10 gauge thickness material

- Galvanized & Cold-Rolled Steel, Stainless, Aluminum, & Pre-Painted or Pre-plated Steels

Bending

7X Amada

- CNC Press Brakes

- 100 Ton Capacity

- 10’ Width capacity

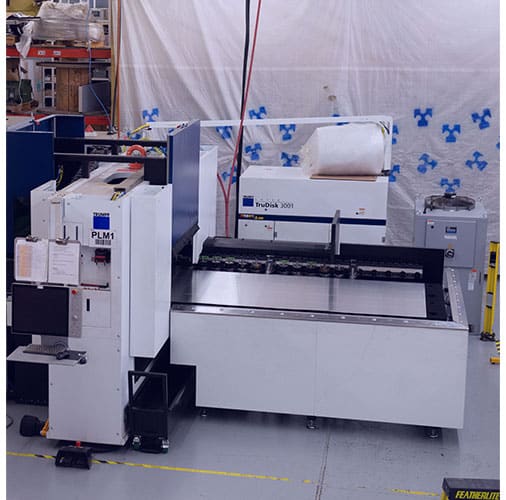

CNC Laser

2X Amada

- Laser cut any shape

- Cuts to 12 gauge thickness material

- Galvanized & Cold-Rolled Steel, Stainless & Aluminum

Additional Capabilities

Shears

Modular Tooling

Pierce-All

Tapping

Metal Assembly Spot welding, riveting and clinch joining

Design & Quality

Design for Manufacturability

Tripar has an incredibly dynamic, creative and knowledgeable design team. When a drawing and/or CAD model (Solidworks & others) is provided by the client, we always review it to ensure its economic manufacturability and freely provide suggestions to make it so. After a collaborative exchange, it is up to the client to decide which version of their product they would like us to produce. Simply bring us your concepts and Tripar will give you innovative solutions.

Quality Control