TriparTech Guides

Where engineers come to learn about all things; metal stamping & CNC fabrication

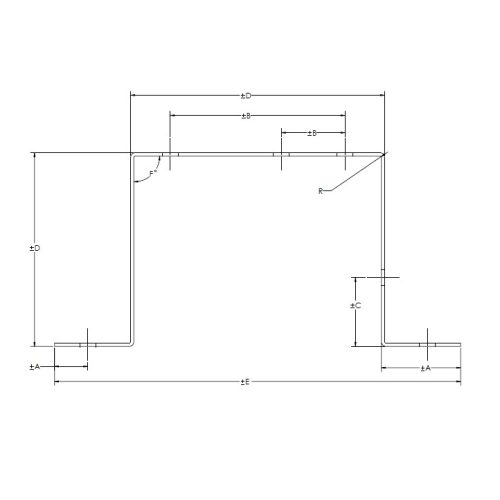

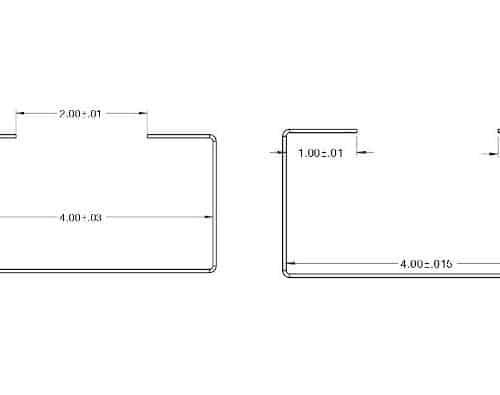

Do you have a project in mind but not sure what tolerances to use? Don't worry we got you covered....

As this subject is vast, this TriparTech will focus on the principal varieties of steel strip (coil) and sheets and...

This TriparTech provides an overview of knockout requirements in luminaires, which are governed by UL1598, Standard for Safety for Luminaires.

Introduction One of the phenomena sheet metal fabricators must contend when bending parts is something called bending allowance. The reason...

This TriparTech on other sheet metal joining options called Fasteners.

The two main operations required to fabricate any part from sheet metal are: 1. Cutting the flat development, 2. Forming...

This TriparTech provides the benefits and limitations of these of Galvanized & Galvanneal Steel, both are commonly available in sheet...

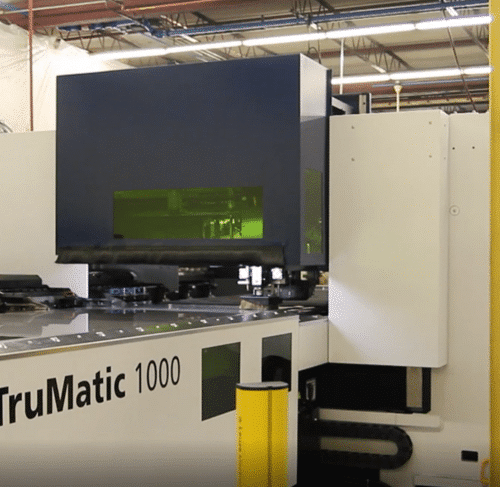

Sheet Metal fabricated parts can be produced by many processes. The two broad methods are metal stamping and metal fabrication....

After publishing “Design for Manufacturability, Part I: Tolerance Tolerant Design” in October 2019, Tripar is pleased to publish a follow...

Based on our experience as both a metal stamper & fabricator, we’re suggesting some best practices to follow when designers...

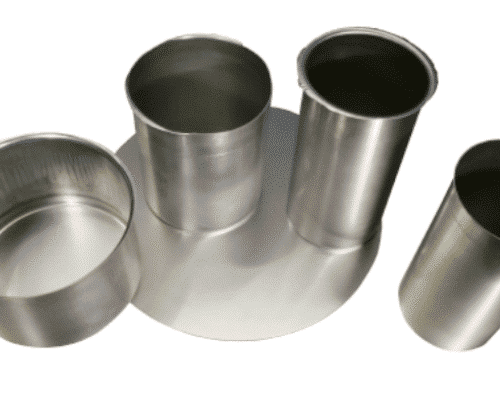

This new TriparTech provides an overview of the characteristics and advantages of the Drawing & Deep Drawing process.

This TriparTech gives an overview of all the characteristics and advantages of Pre Finished Materials, such as offering savings in...

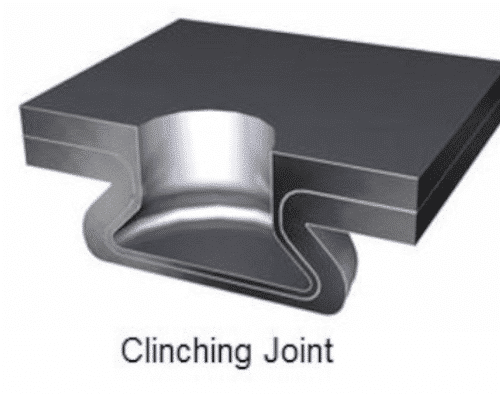

This TriparTech gives an overview, plus advantages and disadvantages of Clinch Joining, which is a process used to join two...

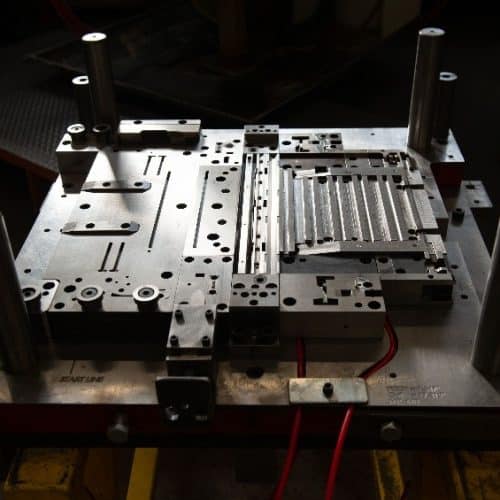

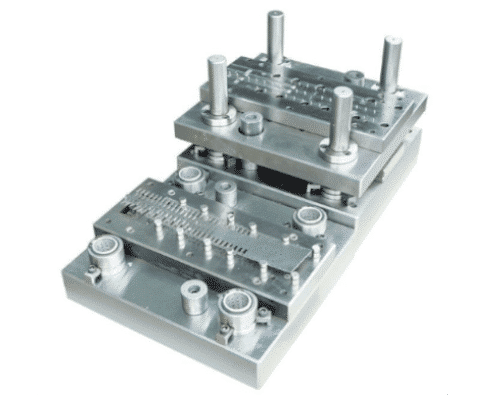

This TriparTech provides an overview of progressive die stamping, which is a sheet metal forming process widely used to produce...