This TriparTech is a follow on from one of our previous editions about “Clinch joining”, however this is focusing on another sheet metal joining options called Fasteners.

Some of these allow for service ability/quick removal of components, cause less damage to cosmetic surfaces, and ease of disassembly for end-of-life and recycling applications, This TriparTech article will provide an overview of a range sheet metal fasteners and characteristics of each of them.

1. Self-tapping screws:

a. Pointed

b. Fluted

c. Drill

2. Rivets

a. Blind rivets (also known as POP® rivets)

b. Semi-tubular (or tubular) rivets

c. Blind rivet nuts (also known as Rivnut®)

3. Self-clinching fasteners

a. Nuts

b. Studs and pins

c. Spacers and standoffs

d. Panel fasteners

4. Weld Fasteners

5. Spring steel sheet metal fasteners

6. Fastener reduction

1. Self-tapping screws

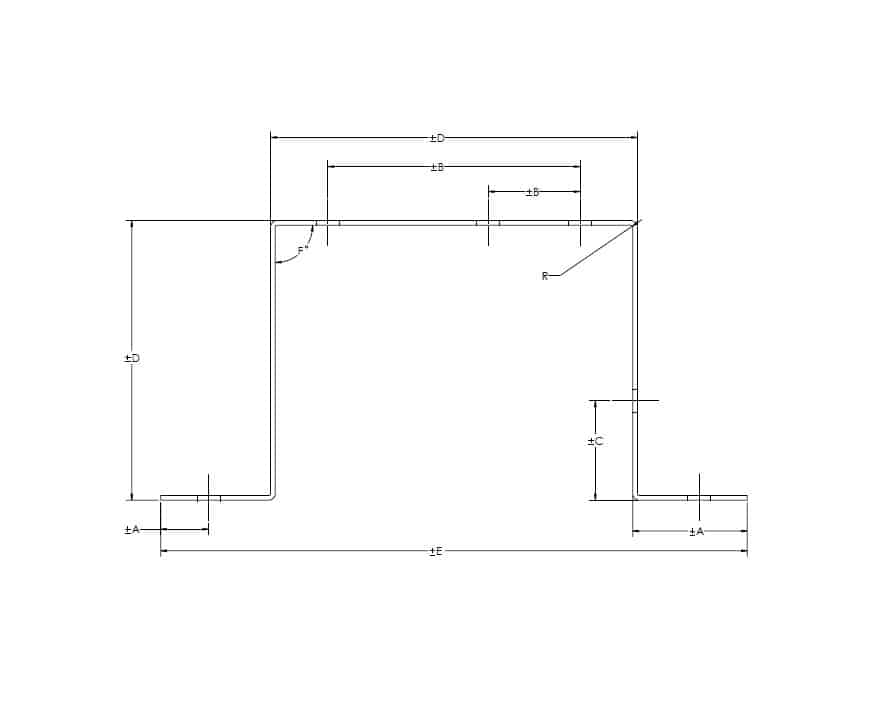

Amongst screws, self-tapping screws are the most used in the sheet metal industry. These offer a low-cost solution for one-time blind assembly to the sheet metal parts (where access is not required or possible on the opposite side), or where disassembly and reassembly is infrequent. They require a clearance hole in the piece closest to where the screw head will be, and pilot hole in the adjacent piece into which the screw threads will engage. Self-tapping screws are recommended for hard materials (cold-rolled steels, stainless steels, etc.).

There are three thread styles of self-tapping screws.

- Pointed: The style that looks very similar to a wood screw containing a coarse pitch.

- Fluted: The thread style is much finer, resembling a machine screw, with a tapered and often fluted tip. These a generally preferred for sheet metal applications, having fine threads that can be specified much like a machine screw (e.g., 8-32, 10-32, etc.).

- Drill: Self-piercing screws are a variation of self-tapping screws not requiring either a clearance or pilot hole, as they have the additional ability to self pierce the metal. These have the characteristic point resembling a drill point.

Considerations:

An extruded hole is recommended if the metal thickness is less than 2-3 times the screw diameter and cannot engage the recommended number of threads. Additionally, if using softer materials, like the aluminum, traditional machine screws (with a nut on the back face) or other fastening methods are recommended.

2. Rivets

These mechanical fasteners provide for easy, economical and permanent connections, requiring a clearance or pilot holes prior to installation. Disassembly is possible, but not intended, and can cause minor damage to the parts.

There are many types of rivets and amongst their variety, below are the most widely used for sheet metal.

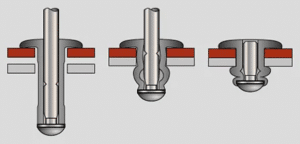

Blind rivets

(also known as POP® rivets):

Ideal for application where access to the joint is limited to only one side, and where no hardware pre-installation is required beside the holes. Blind rivets are available in standard, structural, closed end and various other styles for a wide range of applications. The three phases during blind rivet installation are; rivet installation in holes in the pieces to be joined, drawing of the rivet as the installation tool pulls on the “nail”, and finally with the swaging complete and the projecting nail broken off.

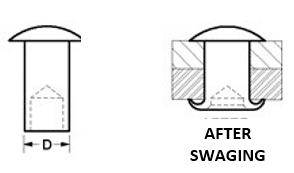

Semi-tubular (or tubular) rivets:

Semi tubular rivets are also permanent fastener similar to solid rivets but contain a hole at the end of the rivet opposite the head, which gets swaged upon assembly.

Semi tubular rivets also require less force needed for application and assembly. The tubular portion of the rivet may be fastened to a tight or loose fit depending on the application. Loose fit (hinged assemblies) is sometimes preferred for pivot points (a joint where movement is desired) since the swelling of the rivet is only at the tail.

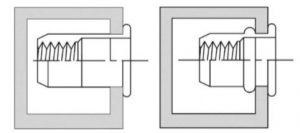

Blind rivets nuts

(often referred to as a Rivnut®):

Available in various sizes for the insertion of stable threaded fittings into thin-walled materials or hollow profiles. This one-piece, threaded, counter-bored tubular rivet can be anchored entirely from one side of the material in which it’s installed. As with a classic blind rivet, the body of the rivet nut is formed on the blind side by a mandrel or a mating screw, pulling the threaded portion of the rivet nut’s shank toward the blind side of the workpiece and forming a bulge around the unthreaded portion.

3. Self-clinching fasteners

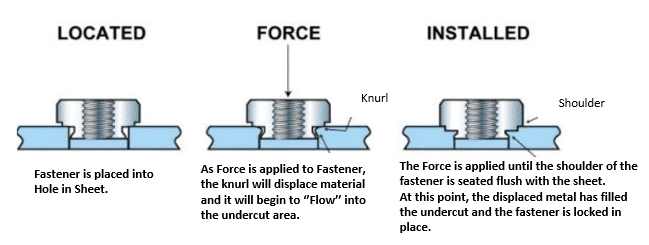

Also known as captive fasteners for non-permanent joints, these offer full specification threads, and great serviceability and disassembly for attaching components to thin sheet metal. Often sold under the PEM® brand, there are many types and variations of self-clinching fasteners. Regardless, they install permanently in thin ductile sheet metal by pressing them into a properly sized hole, swaging them together.

The most commonly used types in sheet metal industry are shown below.

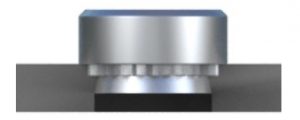

a) Nuts: Standard types are designed with load-bearing threads stronger than those of mild-steel screws. They can vary in size, thread locking properties, style (standard profile, flush, and more), fixed or floating, angle of attachment, and the alloys they are made of. Clinching during installation takes place on the fastener side of the sheet; the reverse side remains flush and smooth.

Standard self-clinching nut

Flush self-clinching nut

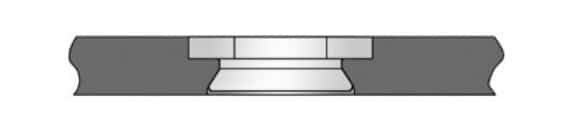

b) Studs and pins: These externally threaded fasteners are used when components must be positioned in advance of final attachment. Flush-head studs are standard, but variations can meet high-torque, thin-sheet, or electrical requirements. Studs without threads can be used as permanently mounted guide pins and pivots.

c) Spacers and standoffs: The most common types of these include thru-threaded and blind threaded versions, and are used primarily to stack or space components. All have their heads flush within the sheet after installation. Using blind-threaded versions leaves outer panel surfaces smooth and closed.

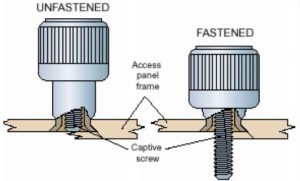

d) Panel fasteners: Self-clinching panel fasteners have captive screws that keep loose parts to a minimum and eliminate the risks associated with hardware that can loosen, fall out, and/or damage internal components. Panel fasteners are well suited for attaching metal panels and other thin-material components if subsequent or frequent access is necessary.

4. Weld Fasteners

Weld fasteners are a good solution for creating a strong and permanent connection between the sheet metal and the fastener. Several varieties of weld fasteners are available as shown below

Weld nut

Weld stud

Weld pins

Depending on the application, weld fasteners can be sometimes be used as a substitute for standard mechanically clinched fasteners, joined by projection weld or spot welding. However, due to the necessary welding process, some weld fasteners are not plated for corrosion protection; so subsequent painting or plating processes may be required to protect the assembly from corrosion.

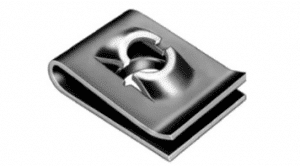

5. Spring steel sheet metal fasteners

This is a class of fastener (often sold under the Tinnerman® brand), made from a type of spring steel, whereby the thread is usually created by integrally formed prongs or features that create a facsimile of a thread. These are available in a variety of styles, such as nuts that are used loose, or that slide or clip onto sheet metal.

When considering these in your designs, some of these may mar the surface, either due to their rotation, locking, or sliding onto the sheet metal

6. Fastener reduction

Obviously, reducing or eliminating fasteners can result in significant cost savings. CNC punching machines (sometimes referred to as “Turret presses”, “Strippits” or “Strippit machines”) can often produce interesting features with low-cost tooling that can reduce and sometimes even eliminate the need for fasteners. Examples include flanges, locking tabs, lances, bridges, keyhole slots, and other formed features. To view more about this please view Tripar’s Design Guide.

Images sourced form different websites such as Araymond-Industria, Hanson Rivet, JHP Fasteners, Machine Design, Monroe Aerospace, Oemfast, Pemnet, Smlease Design & Vogt AG.