Introduction

Though steel artifacts have been uncovered as old as 4000 years, the modern age of steelmaking began in the mid-1800s with the introduction of Henry Bessemer‘s process, which enabled high purity steel to be produced economically in large quantities. Since then, and with increased control, a huge variety of steel alloys and processes have been developed, permitting steel to be used in wide-ranging applications.

As this subject is vast, this TriparTech will focus on the principal varieties of steel strip (coil) and sheets and their uses in thicknesses up to 3/16” thick; what Tripar generally uses. Thicknesses above 3/16” are considered plates.

- 1. Hot Rolled Steel (HRS)

- 2. Hot Rolled Pickled & Oiled (HRP&O)

- 3. Cold Rolled Steel (CRS)

- 4. Galvanized Steel

- 5. Stainless Steel

- 6. Spring Steel

- 7. Galvannealed Steel

- 8. Drawing Steel

1. Hot Rolled Steel (HRS)

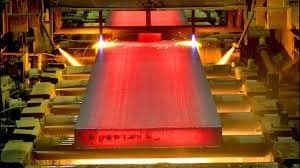

Hot Rolled Steel is the basic form that is produced at the steel mill. It can be produced in more than one thousand alloys depending on requirements. In general, this is produced as a low carbon steel, in accordance with specifications from the American Iron & Steel Institute (AISI). This specification refers to various properties and allowing elements, one of the most important of which is carbon content. For example, AISI A1008/A, a very common low-carbon steel alloy contains 0.08% carbon. Carbon content can range from .02% to .15% depending on specifications. Large slabs weighing up to hundreds of tons and more are continuously cast, cut to length, and sent to rolling mills where the slabs are re-heated to over 1700°F and rolled to thicknesses as low as .059” for mill quantity orders.

Mill quantity orders are about 100 tons depending on the mill. To qualify as a mill customer a company must order at least 600 tons of a product line in a year. Hot rolled steel coil is generally used as the base metal that is transformed into the more utilitarian steels, such as the other types here noted.

2. Hot Rolled Pickled & Oiled (HRP&O)

This is a hot rolled coil that has been cleaned of scale in acid (pickled) and then oiled to prevent rusting. They are usually available from steel warehouses in thicknesses of 1/8” up to 3/16”. This type of steel is used in automotive undercarriages, agricultural equipment, railroad equipment, and just about anywhere that material finish is not critical.

3. Cold Rolled Steel (CRS)

This is Hot Rolled Steel that is pickled and then reduced to a specified thickness by rolling the steel strip through a series of very heavy duty rollers at or near room temperature until the desired thickness is obtained. It is then annealed and/or temper rolled to produce steel with a closer dimensional tolerance and a wide range of surface finishes. CRS is often used in frying pans, home appliances, metal furniture, car and truck bodies, and many other products.

4. Galvanized Steel

This is obtained by passing a prepared cold rolled coil strip through a bath of molten zinc. The zinc coating helps resist corrosion due to barrier protection and sacrificial qualities of the coating.

(For further information on this, please see TriparTech: Galvanized & Galvannealed Steel 101). Coating thickness can be specified from G30 to GXX, which governs the minimum thickness of the coating; (e.g. G30 = min. 0.3 oz/ft2 of zinc coating; the higher the number the thicker the minimum zinc coating permissible). Used anywhere an economical corrosion resistant product is required when appearance is not critical. Used on the lower chassis of washing machines, stoves, and hidden electrical and lighting fixtures.

5. Stainless Steel

Stainless steel is a corrosion-resistant alloy of iron, chromium, and in some cases, nickel and other metals. To be classified as stainless steel, it must have at least 10.5% chromium content (the key ingredient that allows it to resist rust), and less than 1.2% carbon. Common stainless steel alloys, however, are not impervious to corrosion and may be susceptible to attack by various chemicals. It is rolled into sheets and strips (coil) and is available in standard thicknesses (gauges) and different tempers. It can be found in cutlery, thermoses, watch bands, pots and pans, and chimney flues to name just a few of its many uses. There are many different alloys, some magnetic and some non-magnetic, while some which are usually non-magnetic may become magnetic under certain circumstances.

6. Spring Steel

This steel is available as round wire and bar as well as flat rolled; this discussion is limited to the latter. Spring steel is a “high carbon steel” with typical carbon content of at least .35% ranging up to .95%. When supplied in its cold rolled annealed (soft) form, it can be easily cold worked as long as the rolling direction is considered in the final design. Because of the high carbon content, these parts can be heat treated to make them harder and ‘springier’. This steel is also supplied pre-hardened as Scaleless Blue Tempered and Blue Tempered and Polished. Parts made from Blue Tempered spring steel are mostly limited to flat parts or parts with light bends with a very large radius. As its name implies it used to make springs.

7. Galvannealed Steel

Also known as galvanneal or “satin coat”, it is a type of sheet steel that goes through a two-step process: galvanizing and annealing. Galvanneal is primarily designed to be painted due to its highly absorbent matte finish. The improved paint adhesion is better compared to standard galvanized steel due to its zinc coating, allowing paints to adhere more effectively to the surface. In fact, it should not be left bare, otherwise due to the transference of iron to the zinc coating during the annealing process there is the possibility of oxide spots or a reddish hue developing on the surface of unpainted galvanneal; regular galvanized steel is a better choice if it will remain unpainted. Its matte uniform grey color appears consistent, also allowing versatility in design and aesthetic options. It offers a harder coating when compared to galvanized steel with increased durability which provides improved resistance against scratches, abrasion, and wear. However, the increased hardness also makes the coating more brittle, which should be considered when working the material. The matte finish of the zinc coating is much more absorbent than standard galvanized steel which allows paints to adhere to the surface far better.

Due to its properties, it is a valuable option for diverse industrial applications like automotive, construction, and manufacturing. Though rust is not impossible, it is nearly so, in fact, it has to remain exposed in harsh environments for decades. For further information, please read the TriparTech: Galvanized & Galvannealed Steel 101”.

8. Drawing Steel

Drawing is a common metalworking process, in which the metal is pulled and stretched into a three-dimensional shape. In sheet metal drawing, as a die forms a shape from a flat sheet of metal (the “blank”), the material is forced to move and conform to the die.

As the metal stretches, it becomes longer and thinner. Drawing Steel (DS) is a softer steel that typically contains less than .05 percent carbon, and it is generally drawn cold, which means that the metal to be shaped is kept at room temperature rather than heated. It is ideal for canopies, bases, and usually round dished parts.

Square, rectangular, and irregular parts can also be drawn. Increasingly malleable drawing steels may be available (if quantities are sufficient) for deeper draws or complex shapes, in grades such as Deep Drawing Steel (DDS), and Extra-Deep Drawing Steel (EDDS). Drawing is a suitable choice for customers who require their product to be formed or shaped during the manufacturing process, resulting in a consistent shape and thickness. Please click here to read the Tripar Tech “Drawing & Deep Drawing”.