Options to Metal Fabrication vs Metal Stamping

Sheet Metal fabricated parts can be produced by many processes. The two broad methods are metal stamping and metal fabrication. To understand where each comes into play, you must first understand what each is, and what the differences are.

Metal Fabrication

Sheet Metal fabricated parts are those which are typically produced without the use of a metal stamping die (sometimes referred to as “hard tooling”), but instead use dedicated or specialized equipment.

In its simplest/lowest technology form, such equipment would consist of shears, modular tooling such as C-Frame Pierce-All® to pierce holes, slots, etc., and press breaks to do the bending.

In its simplest/lowest technology form, such equipment would consist of shears, modular tooling such as C-Frame Pierce-All® to pierce holes, slots, etc., and press breaks to do the bending.

Moving up the chain of modern technologies to the opposite end of the spectrum, most of this would be replaced by Computer Numerically Controlled (CNC) punch presses (often called a “Strippit”), CNC Lasers, or CNC Punch/Laser Combination machines, followed by bending if/as required using CNC Press Brakes.

CNC Laser

CNC Punch/Laser Combo machine

CNC Press Break

Full sheets would be placed on either a CNC Laser machine where most holes & slots would be punched or cut, or on a CNC Punch Press, where the same features could be punched or cut, and also knockouts, shallow forming* and sometimes tapping could potentially be done, and the entire perimeter of the part punch or cut from the sheet. Some tooling may be required using these processes for custom hole sizes, shapes, or forms, but this is not usually too expensive, ranging from $50-150 for a simple punch and mating die, to perhaps $1500-$2000 for complex forming tools.

*such as extrusions, flanges, louvres and other shallow forming, whose heights are limited by each machine’s specifications.

A CNC Laser can only cut, but can also cut both intricate shapes due to no tooling requirement, as well as large cut-outs, that might otherwise require punching forces (tonnage) that exceed the CNC punch press’ capabilities.

A CNC Punch/Laser Combination machine can achieve both of the above; pierced holes, formed features, and intricate and fine cutting without tooling.

The fully pierced and cut pieces would then be bent if/as required using a CNC Press Break, where programmable and moveable back gauges and stops permit the workpiece to have multiple bends done, often at different bend heights and angles to meet the drawing requirements. These typically require no tooling, or limited tooling, such as small matching punches and bushings for the piercing, and male & female press break tooling for the bending. Most metal fabrication shops have an arsenal of these to suit a wide variety of such requirements, so the customer should bear little or no tooling cost.

Part costs are commensurate with the time it takes to cut parts from each sheet, how they nest within the sheet (which establishes how much material it takes to produce each part), and if/what secondary operations are required such as bending, which consists primarily of labour.

Metal Stamping

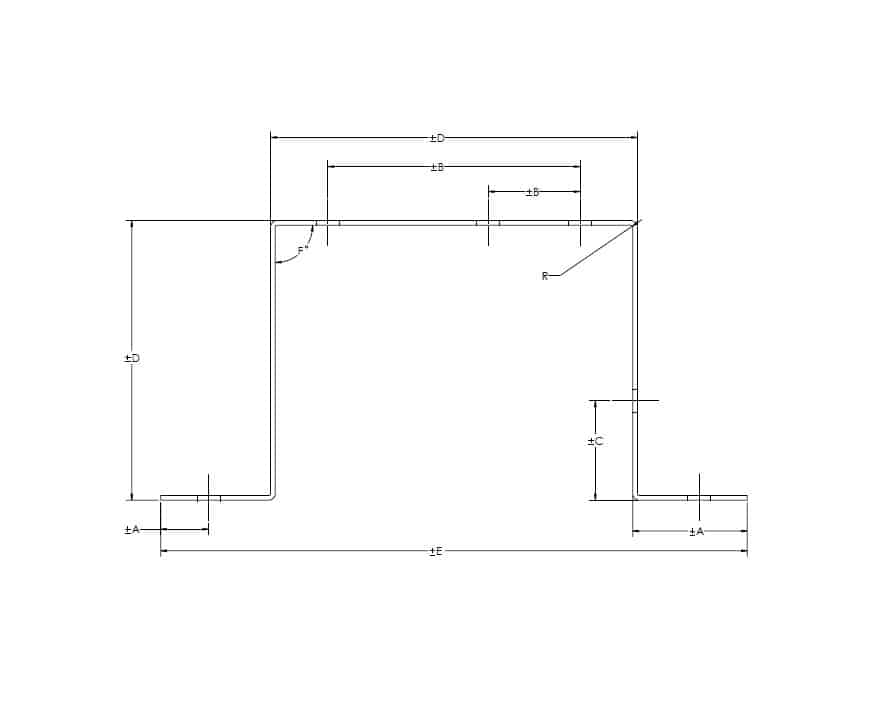

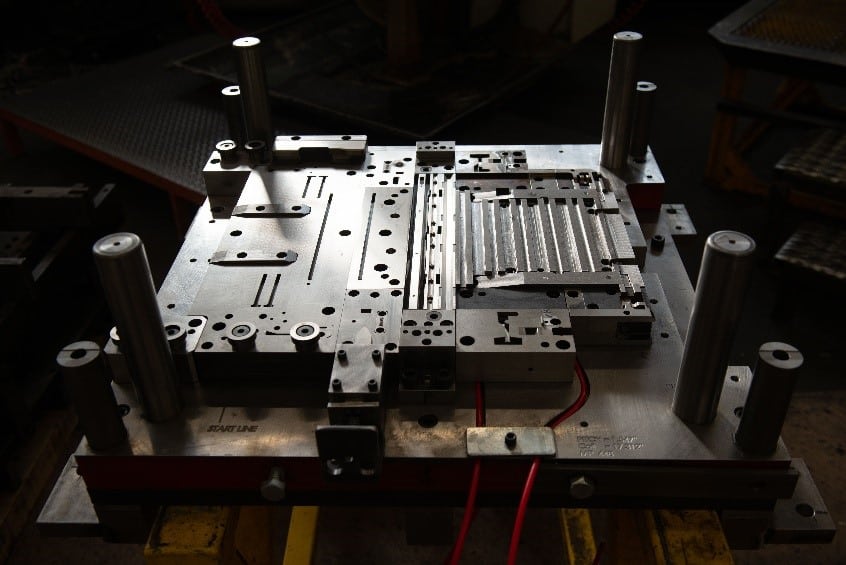

Metal stamping is typically done using mechanical or hydraulic presses of increasing tonnage, and one or more metal stamping dies used to form many or all features of a sheet metal part. These dies can cost anywhere from a few thousand dollars, to $50,000, $100,000, and even more, all depending on the part size, complexity, and to what degree of part completion the die will yield. Small parts that are not overly complex can often be fully produced (i.e., no secondary or subsequent operations) in a progressive die and have the shortest ROI. Larger parts typically involve higher die costs, which can grow exponentially with part complexity.

The primary advantages in having a die that can fully produce a part, are high production rates, and in a single operation, thus relatively low labour cost, resulting in the lowest possible unit part cost, provided volumes can justify/amortize the tooling cost and provide an acceptable ROI.