Pre-finished Metals

Post painting* metals, in North America (typically powder painting) can be done at a somewhat reasonable cost.

Post plating* is becoming increasingly costly, in part due to environmental controls, and also due to closure of many platers unwilling to invest in the appropriate controls.

Pre-finished metals on the other hand (typically steel or aluminum) with painted, plated, or laminate surfaces can provide a competitive and performant alternative. These corrosion-resistant, visually superior solutions to parts manufacturing can save not only money, but manufacturing steps, thus with the potential to also reduce lead time. The cost savings can be broken down into three categories: Manufacturing Costs, Transportation Costs, Material/ Material Handling Costs.

*Please note that hereafter referred to as “post-treatment”.

Markets Served

Prefinished material are used in many industries and for many applications. Examples include:

Home Décor: Wall Plates, Wine Racks, Door Kick Plates.

Range of industries:

- Light fixtures

- Air Registers

- Appliances

- Architectural

- Trophies & Plaque

- Automotive

Manufacturing Process Cost-Savings:

Multiple Finishes: One Tool.

Pre-finished metals have enabled manufacturers to offer their customers multiple finishes without the costs of re-tooling. These run effectively in the same tools as bright stainless, aluminum and other substrates with little or no adjustments.

Bypassing Process Steps/ Reducing Scrap:

A pre-finished metal is ready to be roll-formed, stamped, and further processed right from the coil or sheet it is shipped in. Protective coverings stay on the surface of the metal throughout the forming process to protect the show-face while providing lubricity. There is no post-finishing or treatment required after the forming process. Parts can be simply inspected, packaged and shipped to the end customer. By skipping these processes, customers will see a reduction in scrap costs as well.

Transportation Cost-Savings:

Single Facility Part Completion: While some manufacturers do have painting lines in the same facility as they stamp and form parts, many do not. In facilities that do not, it is necessary that a third-party become involved for post-finishing. This not only creates costs based on the transportation to and from the third-party facility, but also adds cost associated with packaging the parts on both trips to and from as well. There is also the possibility that parts become damaged during transportation, increasing the potential for high levels of scrap.

Reduced Inspections/ Material Handling: Free of a post-treatment, pre-finished metals reduce the number of times that a part must be inspected during the manufacturing process. Post-finished parts that are formed are often inspected before and after painting occurs. Using a pre-finished metal allows one worker to inspect the roll before it is formed and the same worker to inspect the part after. This reduces labor time, material handling, and sortation costs.

Material Cost-Savings:

Protective Film: Pre-finished metals are normally provided with a high quality protective film that can stay on the product until its final step of manufacturing or assembly. By contrast, if additional work must be done to a part post-treatment, this saves the step of re-wrapping the part in protective film before the final work is performed.

Racking: Using a pre-finished metal to manufacture a part eliminates many material handling steps. Inherent in one of these steps is packaging and racking the part before post-treatment. The cost savings here is in the cost of the temporary packaging (boxes, foam, etc.) that must be utilized to protect the part before and after it is moved or shipped for post-treatment.

Customized Backings/Promoters: The final step to part completion is often providing the part with a way to mount it, or adhere it to a final product. Adhesives are a common choice for manufacturers in this step and often these adhesives must be laid down on a surface that promotes it. Pre-finished metals can often be customized with various back-coats that can eliminate the need to paint on a promoter that works with a given adhesive.

Manufacturing Considerations

As with any material that is used to manufacture a product, pre-finished metals also have some inherent limitations that must be kept in mind during design.

Design with Pre-Finished in Mind:

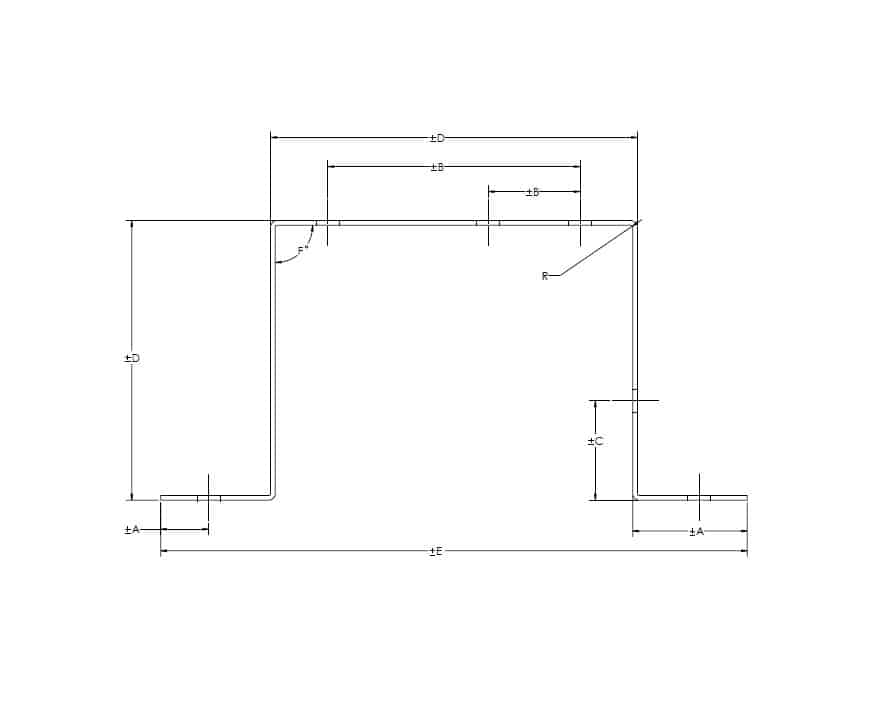

Pre-finished metals are generally shipped in sheet or coil. These sheets and coils come with maximum width that is based on the suppliers’ capabilities. Pre-plated metals are typically available to a width nearing 40”, while pre-painted & pre-laminated metals to widths nearing 60”.

Although the surface is quite tough and impervious to blemishes, with painted, laminated or plated sheet or coil, it is important to keep the raw edges of the product in mind. The pre-finished show-face of the material extends only to the width of the coil or sheet requested. This means that coil and sheet edges, as well as sheared, punched and other cut edges will remain bare, offering reduced protection. For most interior applications this should not cause any problems. If edge corrosion resistance is required, these edges may need to be protected by being encapsulated with a rubber or plastic barrier, or other additive compound (e.g. caulking).

Choosing the Correct Tooling/ Manufacturing Process: Pre-finished metals can be processed in a number of manufacturing processes. These include roll-forming, stamping, co-extruding, laser-cutting and injection molding.

There are some limitations to these processes based on the pre-finished surface that is selected. It is wisest to check with your supplier for recommendations on how to best fabricate the material in your chosen manufacturing process. For instance there are some high-end paints and vinyl laminates that can be processed with a laser-cutter, but they must be protected with an appropriate laser-friendly protective film.

Chances are that there is a pre-finished solution to your manufacturing needs, as there are many pre-finished opportunities that have not been explored.

Customizable Materials Simplify Manufacturing: Many pre-finished metals have a number of customizable options to suit your manufacturing needs. As these metals are produced to suit the customer’s needs, they can come in a variety of gauges, base substrates, surface finishes, protective coverings and top-coats or lacquers. Customizing these material specifications can ease manufacturing in a number of ways. Top-coats or lacquers can help improve anti-corrosion and preserve the show-face for a longer time. These coatings over the show-face can also adjust gloss and at times have an effect on the color of the material as well. Ultraviolet (UV) light resistance to these is…Customizing a protective coating for your tooling can allow for tougher manufacturing processes on a decorative metal and can also be used to increase lubricity in roll-forming and similar forming methods.

Practice Makes Perfect: Transitioning from a post-finished to a pre-finished manufacturing process is best done with a trial and error approach. Not everything that works with a post-finished process will translate to a pre-finished process without some adjustments. It is wisest to explore the many customizable options available to you with your Metal Fabricator.

For more information please contact TriparTech@TriparInc.com.