Overview

When needing to produce a component out of sheet metal there are many options, but the two most commonly used manufacturing processes are metal stamping and CNC metal fabrication. Sometimes the decision between the two options is a clear-cut choice, other times it may be more difficult with arguments being made in favor of one manufacturing processes over the other. Below we will take a look at what is entailed in both metal fabrication and metal stamping processes. Additionally, we will provide some helpful advice for determining which manufacturing process is best suited for your needs.

Metal Stamping

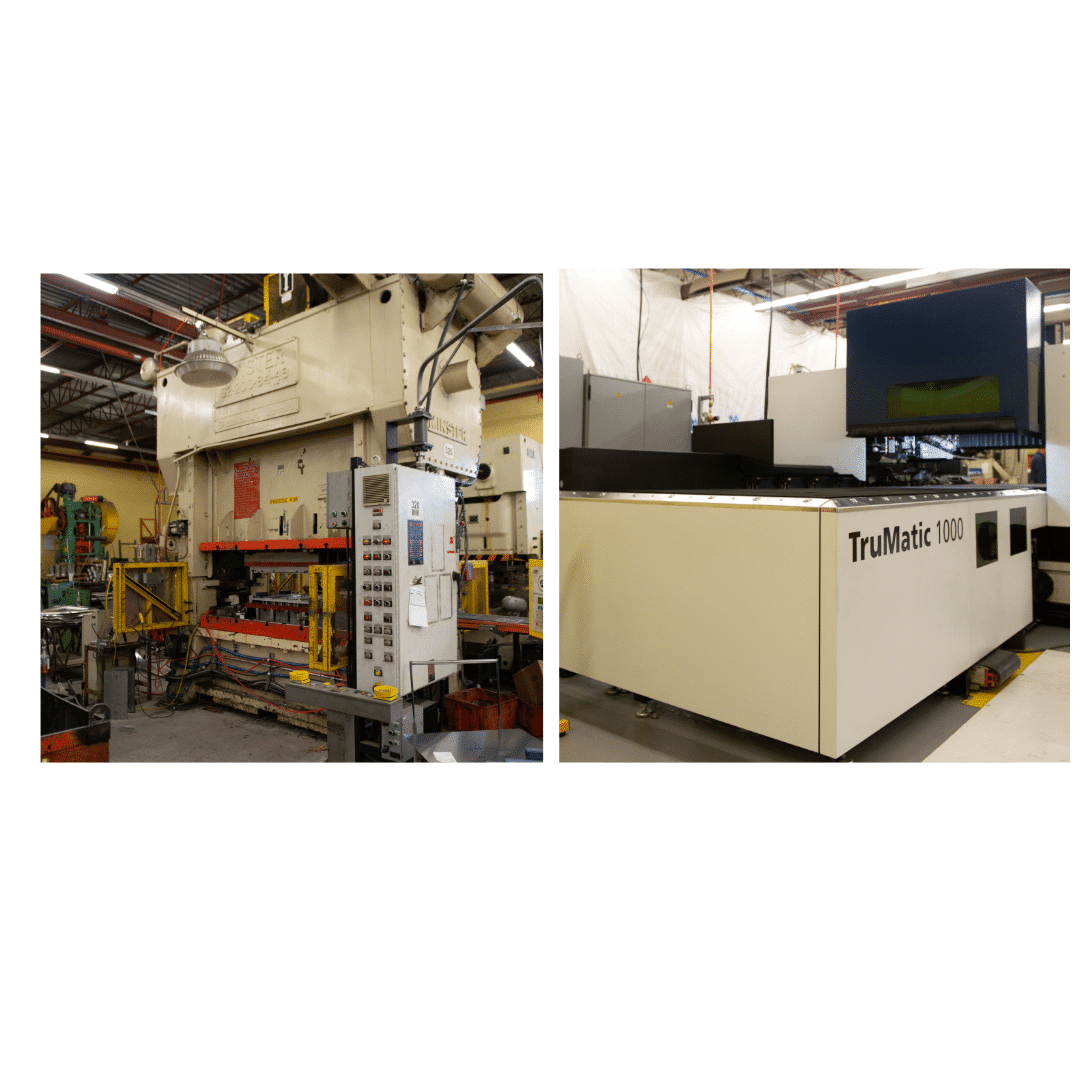

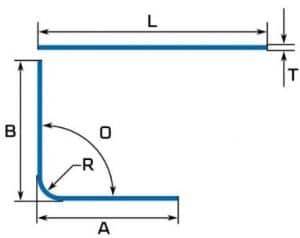

Metal stamping is most often used to transform flat sheet metal into the required 2D or 3D shapes. Metal stamping is typically done using mechanical or hydraulic presses of increasing tonnage, and one or more metal stamping dies are used to form many or all features of a sheet metal part. Some of the techniques used to achieve the desired results are blanking, punching, coining, bending, embossing, drawing, deep drawing, and more.

Metal Fabrication

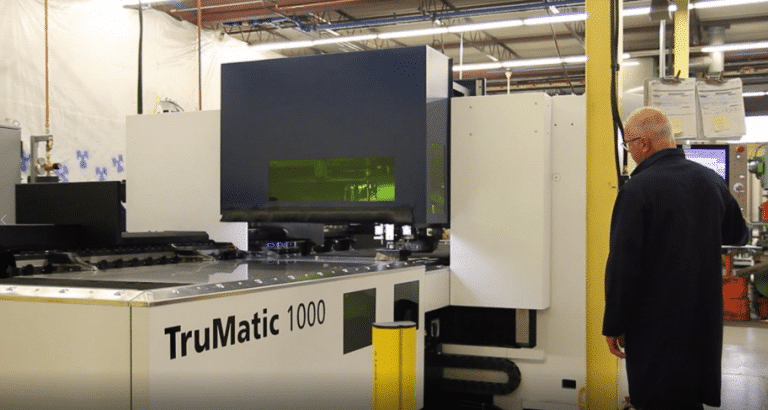

CNC (Computer Numerically Control) fabrication is a manufacturing process whereby computer software is pre-programmed to control the necessary machines movements and tools that are needed to create the desired end product. This process encompasses machinery including punch presses (often called a “Strippit”), CNC Punch Press, CNC Lasers, or CNC Punch/Laser Combination machines, followed by bending if/as required using CNC Press Brakes. Learn more about the capabilities of CNC machines.

Which Manufacturing Process Is Right for You?

Depending on the task at hand, it can be difficult to decide which manufacturing process would best suit your needs and deliver the results you expect. Below you will find a general overview of when CNC fabrication vs metal stamping are recommended for your sheet metal manufacturing needs, including their potential limitations.

Metal Fabrication

Best suited for:

- Lower-mid range quantities

- Short product lifecycle

- Quicker to get the new part to market (days or a few weeks)*

- Easier to adapt or change the design*

*Due to little to no tooling

Limitations:

- Higher labour content so higher unit price

- Slower production speed

Metal Stamping

Best suited for:

- Items with mid-high production quantities

- Obtaining the lowest possible unit part cost

- Long product lifecycle

- Better & more consistent quality and lower scrap rate

Limitations:

- Tooling can be costly

- Leadtime to design and produce dies means longer to get the new part to market (months)

Hybrid Manufacturing

Luckily, there is the potential to get the best of both worlds, and this is a term we have coined as Hybrid Manufacturing. This manufacturing process marries the benefits of both metal stamping and CNC fabrication, allowing them to support one another and improve overall production. With hybrid manufacturing, a component can be either fully or partially metal stamped for economies of scale, and then customized to pinpoint accuracy on CNC fabrication equipment. With this option, you are able to get a combination of the benefits from both manufacturing processes while reducing the limitations experienced by only using one. Learn more about the incredible benefits of hybrid manufacturing today.