Trusted Experts Since 1949

Sheet Metal Fabrication for Businesses Everywhere

Get your high-quality metal parts and products in days

- Full turnkey service provider

- Lead times from 3 business days

- Mid to high volume production (min quote 100+ units)

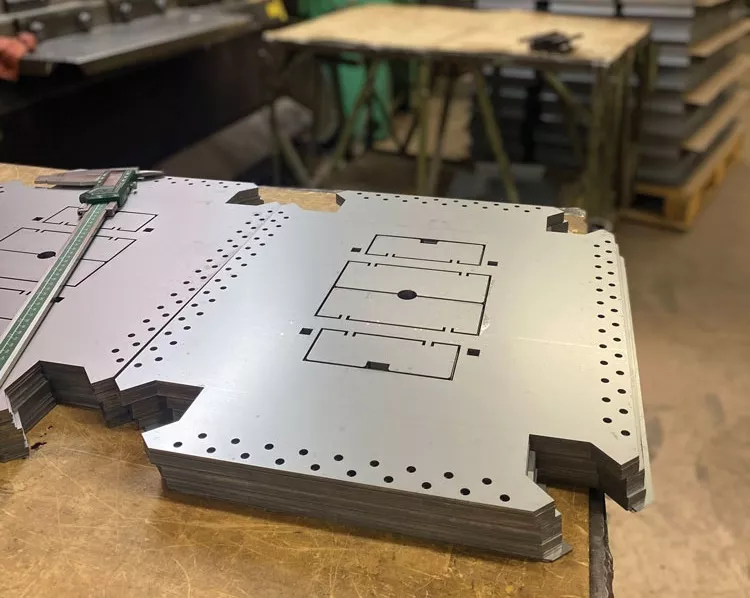

Metal Stamping

With 100+ presses, 1600+ open-tooled dies, and an expert in-house toolroom, Tripar’s capabilities include progressive stamping, blanking, punching, bending, engraving, marking, embossing, rolling, drawing and deep drawing. For high volumes and the lowest possible unit cost.

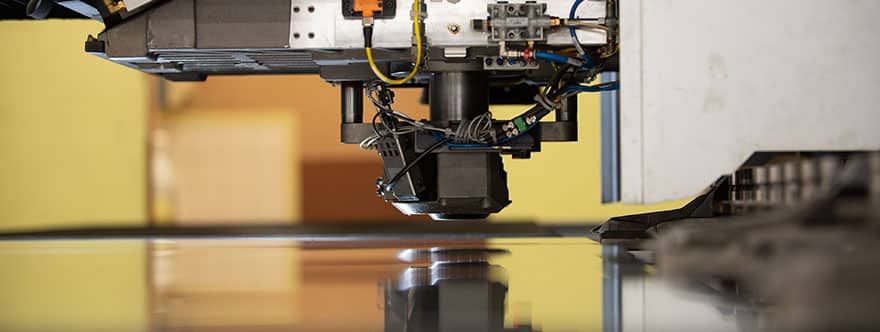

CNC Fabrication

With Tripar’s vast CNC capabilities and experience, we manufacture a wide range of sheet metal components using equipment and processes such as laser cutting, punching, bending, forming, spot welding, shearing, riveting, clinch joining and assemblies too. For low volumes and fastest lead times.

Proudly serving 350+ clients in the US, Canada, Europe and Asia

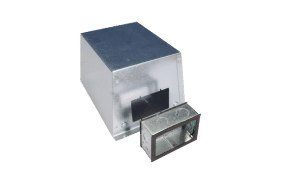

Recessed Lighting

Full line of stocked items: Plaster frames, I.C. Boxes, Junction boxes, Brackets, Hanger bars, canopies for UL1598.

HVAC

Experience manufacturing diffusers, grills, faceplates, louvers, housings, brackets, hinges, nameplates.

Warehouse Racking

Metal components includes shims, brackets and supports for new and existing warehouses.

Appliances/Furniture

Range of sheet metal components for central vacuums, extractor fans and storage cases

Aerospace

Many years producing engraving plates, shielding cans and washers

Engineering & Design Services

We offer full design and engineering services to clients requiring pre-production parts; including Design for Manufacturability (DFM), 3D modelling, technical drawing creation and prototyping.

Knowledgeable Team

Tripar is a highly successful multi award-winning family business with over 75+ years, proudly manufacturing everything under one roof with our incredibly talented and knowledge team. We hold 9 patents for various product innovations.

The Tripar Advantage

What sets us apart

Tripar is one of the few suppliers that offers full hybrid manufacturing; CNC fabrication, metal stamping, or a combination of both processes. Basically, whatever saves you the most money. We help clients at every stage of their manufacturing life cycle; allowing you to scale, reduce risk and costs, and ultimately succeed. We produce a vast range of sheet metal components and products for multiple industries, with quantities ranging from prototypes to millions of units a year.

Turn Your Ideas Into Production

Latest Articles

Tripar in the 60s: A Rapid Expansion

This series continues with the second decade. Tripar quickly outgrew its first premises and then moved in the east end of Montreal, where their first owned plant was erected.

Trapezoid Airtight IC Boxes

Save over 50% on shipping costs with these new stackable Trapezoid IC boxes

In The Media

Canadian Manufacturing

Home vent manufacturer scaling up and growing through partnership

Fabricating & Welding

A great story of Tripar’s hybrid manufacturing approach when quantities scale

Canadian Manufacturing

Two Canadian companies Aria Vent and Tripar Inc. form a collaborative relationship

Axya

Tripar Inc: Strength and Savings Through Domestic Production