New Product Bulletin – Torsion Spring & Bracket

Suspending lighting trims using torsion springs has been around for decades, but with the anchoring means integrally designed into the light fixture.

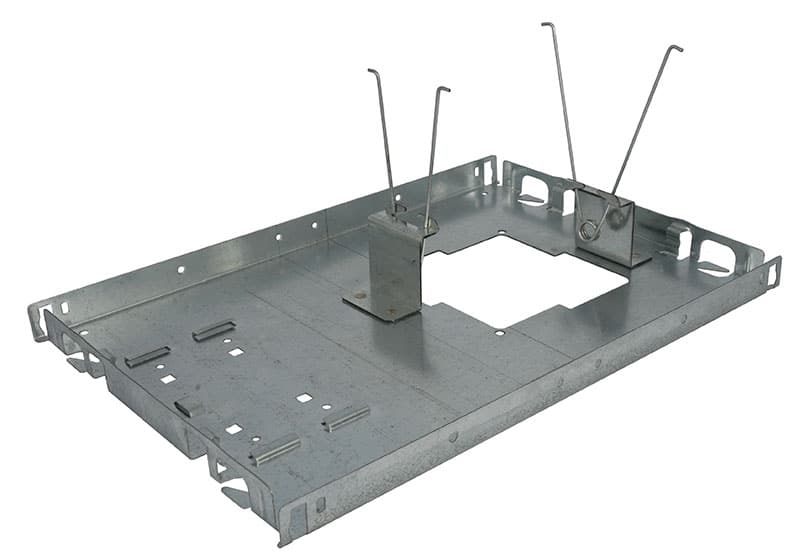

Though not wildly innovative, but extremely practical, Tripar is pleased to offer two types of torsion spring brackets & the torsion spring, permitting this proven suspension system to be easily incorporated into almost any light fixture.

Offered in two models;

Item # 1450-1, Bent foot Torsion Spring Bracket:

2” tall and with bent foot for horizontal surface mounting via a pair of 1/8” rivet mounting holes.

Item # 1450-2, Straight Torsion Spring Bracket:

2-1/2” tall with straight foot for vertical surface mounting at one of two heights via your choice of two pairs of 1/8” rivet mounting holes. The straight foot bracket also contains a score mark, allowing easy bending to convert it to the bent foot model.

Brackets made from .05” thick x 1-5/8” wide galvanized steel in a progressive die for competitive prices.

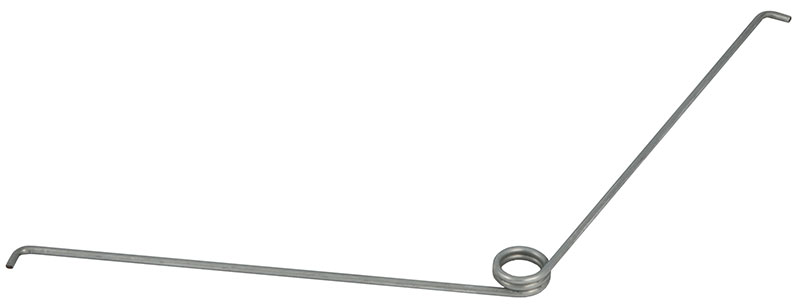

Torsion Spring PP398

Also available is our compatible Torsion Spring, made from 1/16” music wire and containing 4-1/2” legs.

To obtain more information please contact our Sales Team at Sales@TriparInc.com.