New Product Bulletin – LED Downlight Assembly Kit

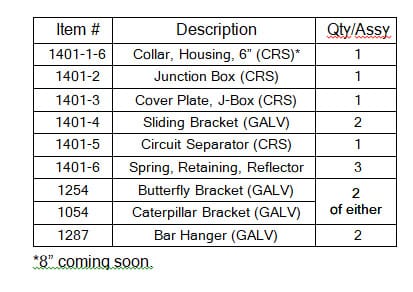

Tripar is pleased to offer components for a 6” downlight* for OEMs to design and incorporate LED Modules.

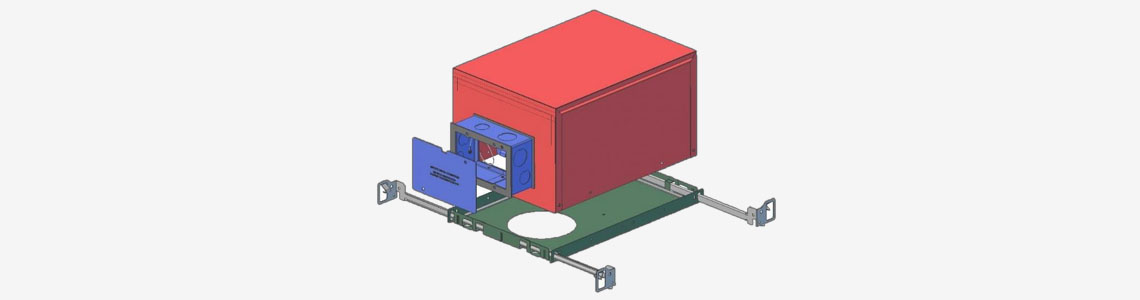

For new construction or remodel, non IC accessible or suspended ceilings. Luminaire, trim, and LED module can all be installed independently.

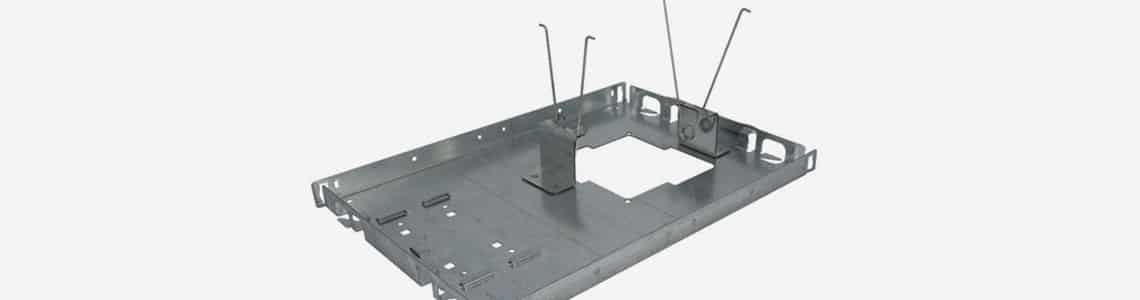

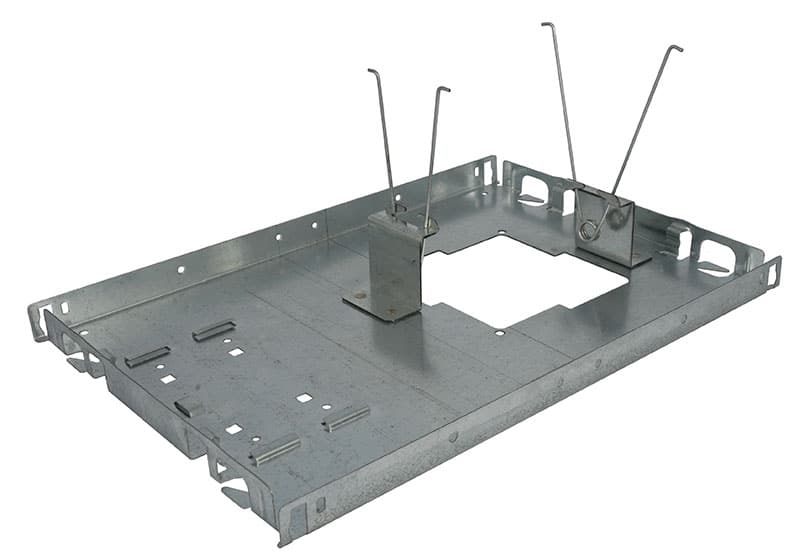

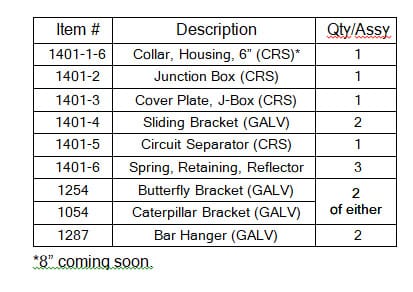

LED modules install into the Snap-on Cover Plate, the removal of which provides access to the 7” x 5 x 1-3/4” high integral junction box. Ideally suited to hold the OEMs Driver/Heat sink assembly, the Junction Box contains double knockouts for a combined total of ten knockouts; six ¾”, and four 1”, all designed for conduit connections suitable for through branch circuit wiring. Both the Cover Plate and Junction Box mounting holes are configurable to suit OEM specific requirements.

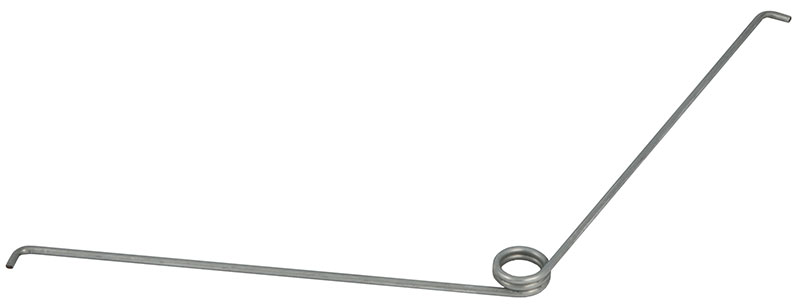

The collar contains a 1-3/8” tall flange and accepts three dual contact retaining springs to hold the Trim/Reflector securely to the finished ceiling, easily withdrawn for LED module replacement or painting. Compatible with ceiling thicknesses from ½” to 1-1/8”.

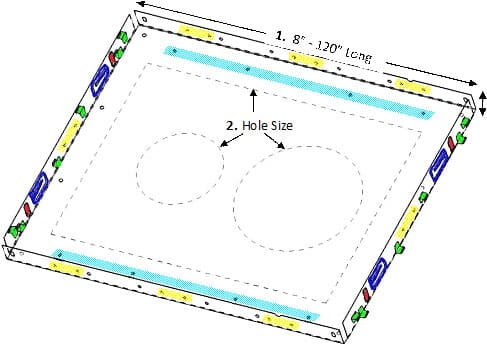

Either our 1254 Sliding Butterfly Brackets or our 1054 Caterpillar Brackets provide for 3” vertical adjustment, and permit suspension via our 1287 C-channel bar hangers. The Butterfly Bracket also permits additional means of suspension; conduit, furring strip, C-channel, etc.

Rigid design provides for secure mounting, constructed in your choice of 18 GA galvanized steel, or cold-rolled steel ready for powder painting.

Please note the Trim/Reflector is not included in the kit, only shown for illustration purposes

All parts made in progressive dies for the most competitive pricing. Contact one of our Sales Representatives at Sales@TriparInc.com .