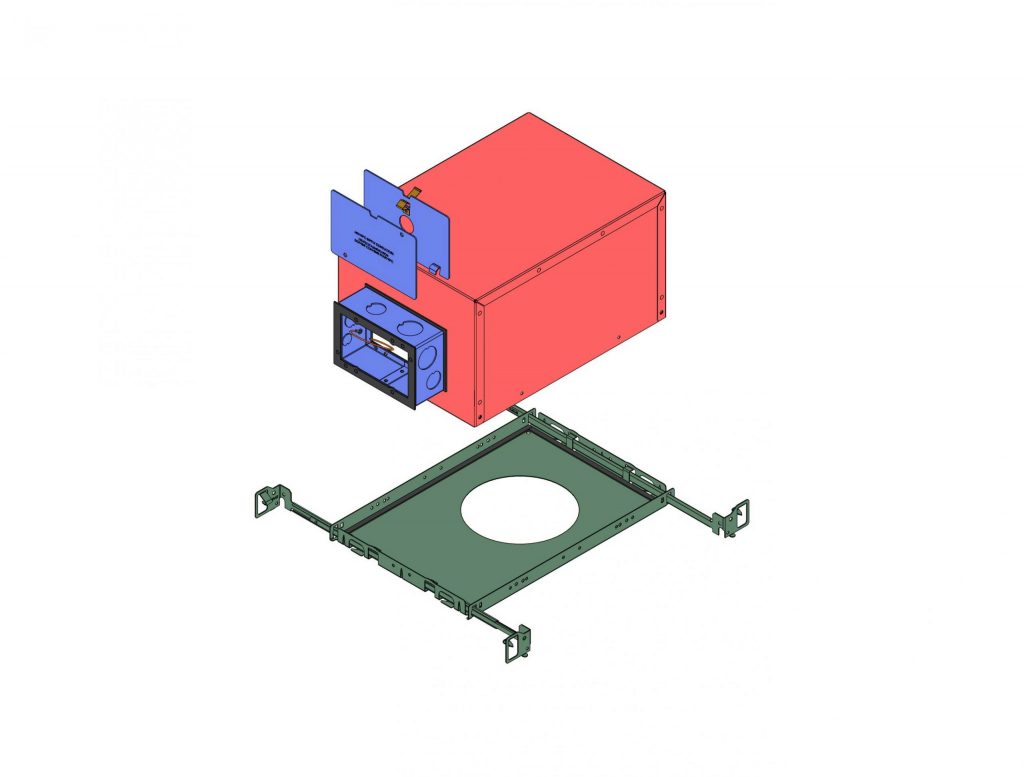

Tripar recently received an RFQ from a US based OEM for 20,000 of its 1287 bar hangers. A quote was provided, and we received a P.O. – nothing unusual but one thing; the ship to address was China!

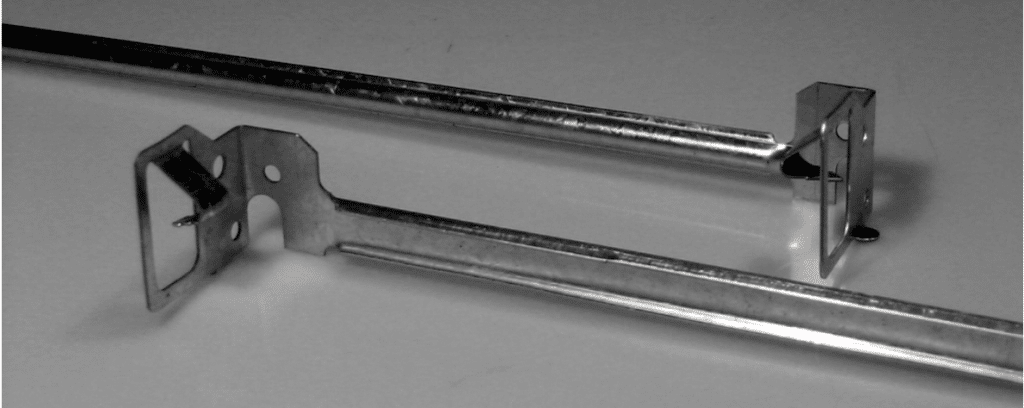

Intrigued, we reached out to our customer to find out more, who it turns out has all their components, assembly, and packaging done offshore, importing the final product. Upon reviewing their components costs, they spotted the price they were being charged for bar hangers which they thought was high. Knowing Tripar’s strength as a lighting component manufacturer, they reached out to us with an RFQ for this item. Not only did Tripar’s bar hangers cost less, but sufficiently so to justify the US OEM buying them from us, paying for the shipping to China, at which point 2 sets were added to each boxed assembly, and then shipped back into the US!

This is a perfect example of successful reshoring and Tripar’s competitiveness;

1. Reshoring; Besides this US based OEM reverting back to Tripar, a North American source for its bar hangers, it is studying doing so for the reminder of the components used in this and other assemblies. Such reshoring not only greatly reduces lead time, but also order sizes, inventories, warehouse space, and risk by not having to predict needs 12-14 weeks ahead of offshore deliveries. Lastly, most goods manufactured in North America fall under the US-Mexico-Canada Agreement (USMCA), which permits duty & hassle free entry and trade between the three member countries.

Most of this is described in more detail here; https://www.esict.com/blog/why-more-oems-reshoring-manufacturing/

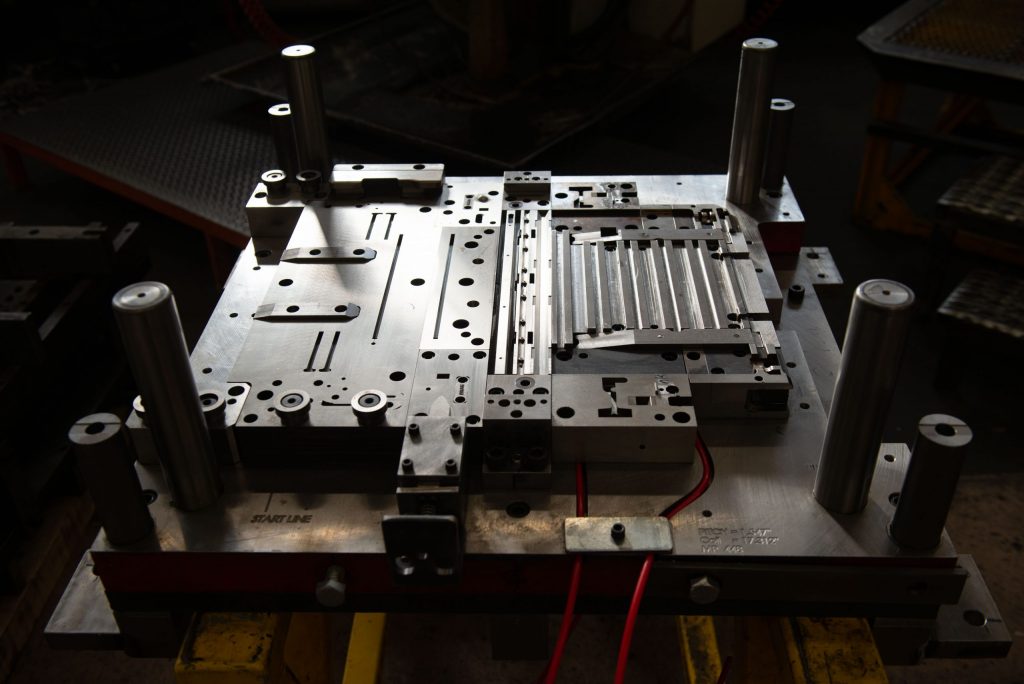

2. Tripar’s competitiveness; Achieved in this case through the use of a progressive die that pumps out a bar hanger set on every stroke (one male and one female bar hanger), and a high degree of automation. This results in the parts falling straight into a box with very little labor. Since the overwhelming majority of the cost is in the material, and steel being a world commodity for which most countries pay almost the same price, Tripar was able to be as competitive as Asia!