Canadian Metalworking Magazine

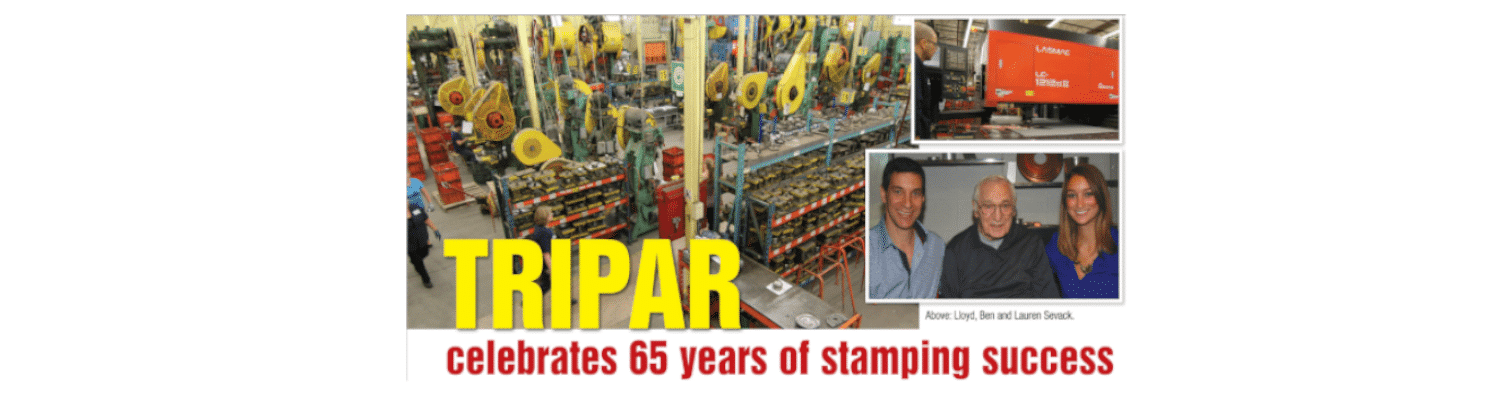

Over four days in early November 2014, Montreal- based Tripar Inc. opened its doors to customers and suppliers to celebrate the metal stamping company’s 65th anniversary. This event was made doubly special when 91-year-old Ben Sevack, the company’s founder and chairman, made an appearance.

The well-attended open house was symbolic of the company’s core strength of building long-term relationships with its customers, one dating back since its inception, while also maintaining strong family values and a willingness to share the expertise the company has acquired over three generations.

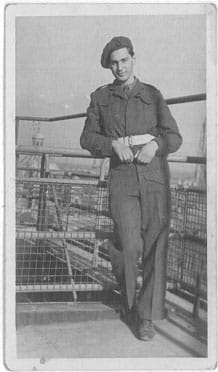

Tripar’s specialty lies in metal stamping (mainly progressive, draw & deep draw), with an international reputation for its work in the commercial and architectural lighting industry. The business originally started in 1949 by three partners, thus the Tripar name. It was brothers Ben and David Sevack, who were recent immigrants from England following the Second World War, and a local man who was connected to the die making trade. Before long it was just the Sevack brothers who were running the metal stamping business, but the Tripar name stuck.

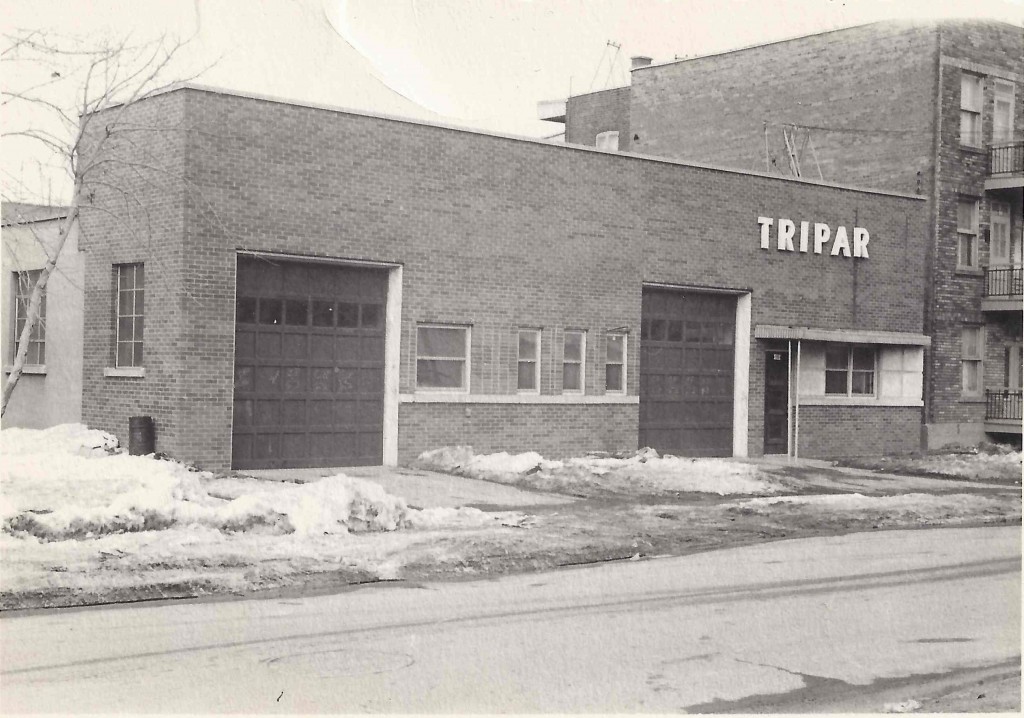

Initially located in a 4,500 sq. ft. building on Hays Avenue in Montreal, the company moved to a 10,000 sq. ft. space in northeast end of Montreal Island after its 10th anniversary in 1960. Now after four rounds of expansion Tripar occupies a 65,000 sq. ft. plant. “We have enough space for now,” says current company President, Lloyd Sevack, Ben’s son, although he doesn’t discount potential expansion in the future.

An engineer by training, Lloyd worked for two companies over 15 years prior to joining the family business as vice president in 2001 after his uncle had retired.

Since its earliest days Tripar has been well known to the lighting fixture industry. Lloyd notes that today around 80 per cent of its business comes from lighting OEMs. “We’re very responsive to that market. We can modify tooling, often giving customers exactly what they want with little or no tooling cost,” he says.

Tripar does resists competing in the high-volume, low- end, residential lighting space, the products typically found in the big box hardware stores where deals like a six-pack of recessed lights run for $50, with light bulbs included. “It’s all made in China and of terrible quality,” says Lloyd. “But that’s not our market. That’s practically a throw-away market.”

Metal stamping in North America is a challenging business and a lot of work has moved overseas, but Lloyd does see some work coming back. “It’s not a tidal wave, but it is happening.”

Lauren Sevack, Lloyd’s daughter, joined the company in a sales and marketing role in 2013. She relates the story of one local customer who had shifted its manufacturing to China years ago and recently rediscovered Tripar. “They called us because they were in a pickle and knew we were always there to help them,” she says.

Tripar was able to quickly turn around their request, and Lauren followed up by asking for the opportunity to quote on the bulk of their work. “I wanted to see how close we were to the pricing from China. I know we are competitive, and we’re constantly innovating.

“Well, their mouths were on the floor when we quoted, and they said, you’ve won our business back.”

It’s a combination of being local and a focus on quality that works in their favour. “The reason we got the opportunity to regain their business was because they had ordered a thousand parts from China and more than half were scrap,” notes Lloyd.

The company is not only winning back business from local customers but is also growing its relationships with European lighting clients. “We have customers from France, England and Belgium and we’re in discussions with firms in Denmark and Germany. All for the same reason, they’re eyeing the North American market,” says Lauren.

As the European economy remains stalled these OEMs see the North American market ripe for expansion. The firms find Tripar, often through referrals, and take advantage of their expertise with North American construction and electrical codes, and the company’s ready supply of existing parts. “Initially we may be shipping components to Europe, where they assemble them and ship them back to North America, but more and more the European firms are setting up shop somewhere in North America to assemble and deliver from here,” says Lloyd.

Although modest in their Canadian way, the Sevacks are convinced they are the largest firm in North America specializing in the lighting market “We get told that all of the time,” says Lauren. “We don’t know if we’re always safe to make that claim, but then we have customers who tell us that we’re the only ones who do what we do.”

“I know of a few others that do other aspects of lighting, but we’re the biggest,” says Lloyd. And with 65 years in operation the company’s knowledge is valued.

“The number one feedback I get from our customers is that they love our expertise,” says Lauren. “They know that at any point they can come down, sit with our team of engineers and work out their problems. We care about finding solutions, and for the lowest possible cost.”

“As much as we try to diversify out of lighting—which we do—we still continue to get more customers within lighting,” says Lloyd, “particularly now with the evo- lution of LED lighting which has taken place with such rapid speed over the last three to four years. New companies keep popping up.”

The company certainly handles jobs outside of lighting as well, listing off projects including air purifiers, gar- dening tools, and project supplies such as xylophone kits and blind shelf supports. The company’s largest single contract was to manufacture a racking system for a massive (500,000 sq. ft.) grocery chain’s automated storage & retrieval system.