Over the last few years there have been many changes in technology, industry, our capabilities & personnel, and now worldwide with Covid-19.

Continue readingNewsletter March 2020 TriparTech and Case Study

Web Site News

Tripar continues to update its website and just recently published

its 6th TriparTech and 3rd Case Study.

TRIPARTECH

After publishing “Design for Manufacturability, Part I: Tolerance Tolerant Design” in October 2019, Tripar is pleased to publish a follow on to this with ““Design for Manufacturability, Part II: Feature Design”.

Please click here to learn more about all the advantages of proper Feature Design in the latest TriparTech.

CASE STUDIES

Another success story on how Tripar was able to better assist its clients and develop innovative solutions is demonstrated by the following Case Study:

This is now showcased on our website. Please click here to see more case studies.

Want to see what Tripar’s engineering team can do to help your business? Challenge us to see what can be achieved!

Newsletter January 2020 Tripar’s 70th Anniversary Xmas Party

Tripar’s 70th Anniversary XMAS Party

Tripar closed off the year with a fantastic Xmas Party!

On December 20th, 2019, Tripar hosted a special holiday party for all its employees and their significant other to celebrate its 70th anniversary.

This was a great opportunity for the entire team to spend quality time together, eat well, dance and congratulate our president Lloyd and his family on Tripar’s 70th anniversary!

This was a great opportunity for the entire team to spend quality time together, eat well, dance and congratulate our president Lloyd and his family on Tripar’s 70th anniversary!

Web Site Updates

Tripar continues to update its website and just recently published the following two new pages:

MEET THE TRIPAR TEAM

It’s always nicer to know who you are dealing with! This new section will introduce you to many of the Tripar team who work effortlessly to cater to our clients’ needs. Please click here to see this new page.

CASE STUDIES

Tripar constantly looks for ways to better assist its clients. This is best demonstrated when Tripar’s engineering team consults its clients to develop innovative solutions to meet their evolving demands. Superb examples of this commitment are presented in the following case studies :

These two are the first of our “Case Studies” series, which are now showcased on our website. Please click here to see this new page.

Want to see what Tripar’s engineering team can do to help your business? Challenge us to see what can be achieved!

Newsletter October 2019 Tripar’s Open House

Tripar Open House: Our 70th Anniversary Celebration

Tripar is excited to announce that last month’s Open House celebrating our 70th  anniversary was a great success!

anniversary was a great success!

On Sept 24th, we had the pleasure of welcoming Tripar’s founder and our president’s father, Ben Sevack, as well as the entire Sevack family during our first day! Ben & Lloyd cut the cake together to symbolize the strong bond that binds both to Tripar and theirselves.

We were also honored to receive Rivière-des-Prairies’ Mayor, Caroline Bourgeois, Karim Elfilali from the City of Montreal, Simon Gaudreault and Marie Quesnel from CFIB, who were all present during our festivities.

Many of our clients took part in the event, visiting us from across Canada and the United States.

During the 3 day-event, Tripar’s management and staff were happy to give tours of the factory, explaining what we do and demonstrating their passion for our facility and operations!

Our 70th anniversary celebration also marked Tripar’s longevity, as Mr. Gaudreault declared: “Today is very hard to find such a long-lived company in the Quebec area”. We agree and couldn’t be happier to be so well supported by our clients, partners and community.

With City Of Montreal

Ben & Lloyd Sevack with the Mayor Caroline Bourgeois & Karim Elfilali, Commissioner for Economic Development.

With CFIB

Ben, Lloyd & Lauren Sevack with the Senior Director of National Research Simon Gaudreault and Bussiness Counsellor Marie Quesnel.

Newsletter April 2019 New CNC Punch/Laser

New CNC Punch/Laser Combination machine:

Tripar has expanded its metal fabrication capabilities over the years with a CNC laser, several CNC Press Breaks, and just last year a brand new CNC Punch/Laser Combination Machine. This incredibly versatile machine often permits the complete processing of workpieces, since many features can be achieved in a single operation; not only punching & laser cutting, but also tapping, forming, bending, extruding, marking of components, and more!

The machine is focused on between the time segment 0:20 to 0:45.

![]() Please click here to watch more Tripar’s videos on our YouTube channel.

Please click here to watch more Tripar’s videos on our YouTube channel.

To fully benefit from this machine’s amazing design and manufacturing possibilities, we have produced our CNC Punch/Laser Design Guide, permitting you unlock its true potential. Please click here to download it.

In fact, some of you have had your parts quoted and produced on this machine without even knowing it; a testament to its competitiveness, versatility, and precision!

Newsletter January 2019 70th Anniversary

Tripar 70th Anniversary

1949-2019: Tripar, your trusted partner for 70 years and counting…

2019 marks Tripar’s 70th anniversary! Lloyd Sevack, President has written an open letter to mark the milestone.

To all our valued customers,

When can a company be called a legacy? If longevity and reputation are two measures, I think that Tripar can claim such status. Having been founded in 1949 by my uncle, David, and my Dad, Ben Sevack, my entry into the business in 2001, and the third-generation present, with my daughter, Lauren, Director of Human Resources, this year, 2019, marks our 70th anniversary!

Much has changed since Tripar’s founding, from a rented space with 3 employees and a few presses….Please click here to continue reading the full letter.

Canadian Fabrication and Welding Article

Tripar is featured in the latest (February, 2019) issue of Canadian Fabrication and Welding magazine. Click here to read more about all that Tripar offers, including some of our evolution, challenges, and how we are meeting them. Please click here.

Newsletter October 2018 Tripar Tech

TriparTech

We are pleased to launch “TriparTech”; a new series of technical bulletins.

These will be published every 1-2 months, each covering a technical subject that we are certain you will be able to benefit from; be it for design, manufacturing, material, or cost related reasons. These are drawn from Tripar’s engineering knowledge and manufacturing experience in a wide range of manufacturing processes.

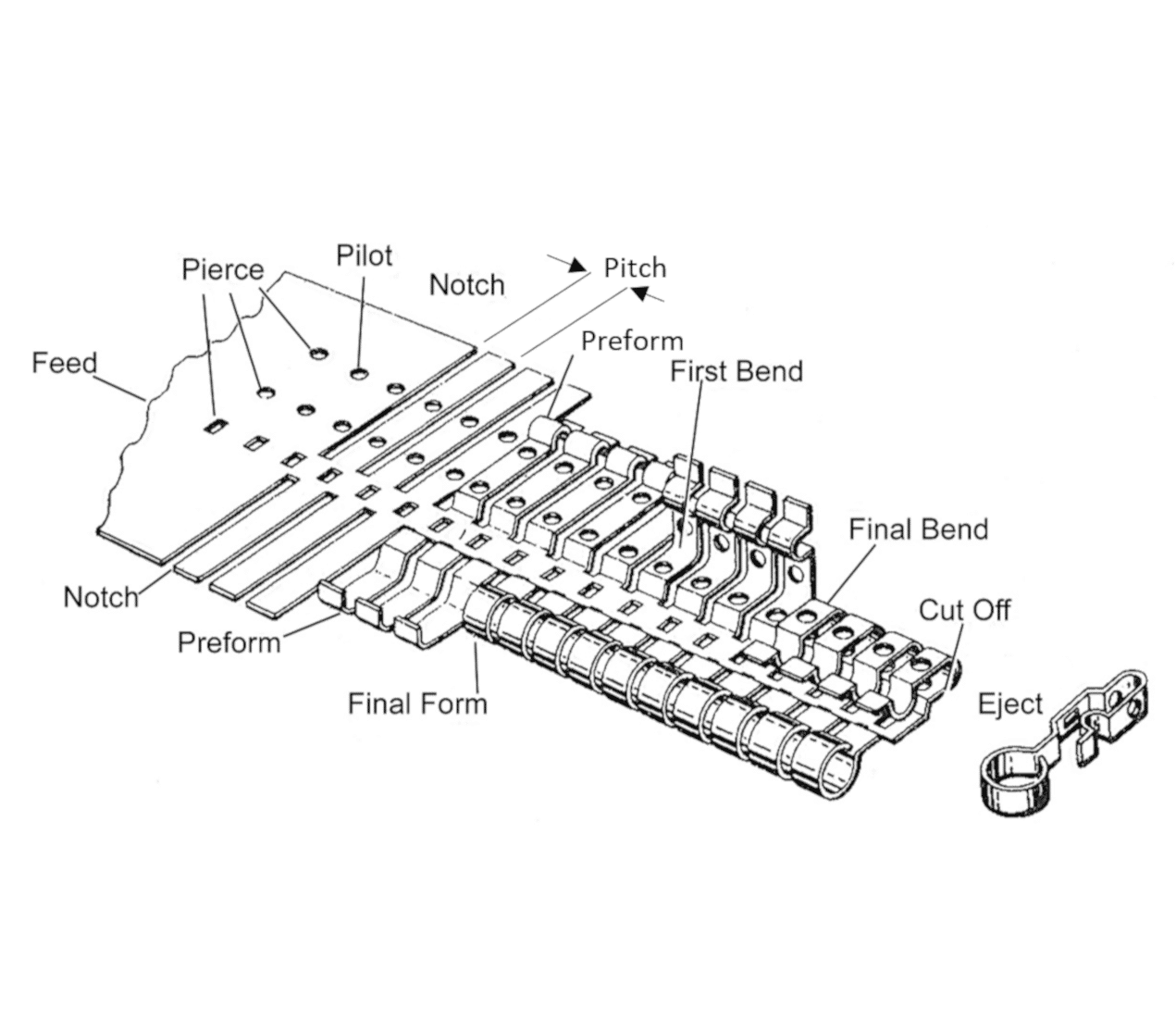

The first TriparTech bulletin is entitled: Progressive Dies and Progressive Die Stamping, providing an overview of the process, the financial considerations, alternatives, a video showing the process, and conclusions. Please click here for this first TriparTech.

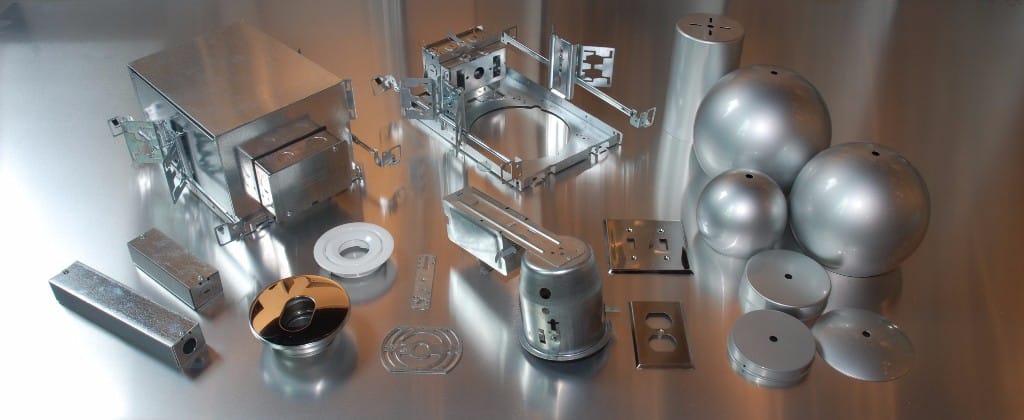

Stocked Items

Tripar manufacture and stock a range of over 30 different Lighting components for OEM’s. These include Plaster frames, Junction boxes, I.C. Boxes, Brackets, and Bar Hangers. To view the full list of stocked items available, including the release quantities based on complete box sizes (and full skid or pallet), please click here.

The benefits of utilizing these stocked items include:

- High quality stamped components benefiting from economies of scale

- 48hr Lead time (for complete box quantities and multiples of box quantities)

- Feature packed components that can only be achieved when stamped

- All components designed to fit together for complete assembly or used separately in own fixture

- All designed to meet UL1598 regulations

If you are unable to attend the show and would like any more information, please contact Connie Muro at Connie@triparinc.com.

Newsletter April 2018 Lightfair Chicago

Lightfair Chicago 2018

May 8th – 10th Tripar will be exhibiting at Lightfair International for the 15th straight year. This year in Philadelphia, Tripar will be on Bill Brown Sales/ALP Lighting’s Booth #2019. Every year is always enjoyable at the show seeing new trends in the industry, but undoubtedly it is the face to face time we have with both old and new customers that we look forward to the most.

In 2018 Lightfair continues the paperless On-line VIP Pass Program which we invite you to take advantage of. Simply click on the link, copy the code (V24878), and register online for your VIP Pass.

Your VIP Pass Code is: V24878, please click here to register.

Be sure to visit us at Booth Number: 2019

New Capabilities

Tripar continually strives to employ the best practices so that we can offer our clients optimal quality, design assistance, manufacturing, and delivery, all at competitive prices to allow OEM’s the best chances to succeed in highly competitive markets.

Tripar has just become the first company in Canada to purchase this brand-new machine, propelling our capabilities to the forefront of the industry! This unique combination allows Tripar to manufacture a range of highly complex components, from prototypes & small quantity runs, to mass production of multimillion pieces per year.

Please come and visit us at Lightfair to see what machine we bought and how it can help you produce higher quality and more cost-effective components.

If you are unable to attend the show and would like any more information, please contact Connie Muro at Connie@triparinc.com.

Newsletter December 2017 New Capabilities

New Capabilities

In keeping with Tripar’s vision to remain at the forefront of metal stamping and sheet metal fabrication technology, through 2017 Tripar have invested in many new capabilities; namely CNC milling, additional CNC Press breaks, Wire EDM and Heat treating. We continue to invest, with a state-of-the-art CNC machine (the first in Quebec and only the second in Canada) to be announced in early 2018. All these new capabilities allow Tripar to develop and manufacture increasingly innovative and superior components at the lowest possible cost.

More important to Tripar than our manufacturing capabilities is the quality and service we offer our clients. This is showcased best when Tripar’s engineering team work with clients to develop innovative solutions to meet client demands. Superb examples of this include:

- Tripar’s L-Bar

- Ultra-Airtight I.C. Box

- Deep Drawn Cylinders

These three examples are the first of our “Success Stories”, which are now showcased on our website.

As also stated in our vision, we “Collaborate with customers to solve their problems with innovative solutions quickly, competitively, and at any volume”. Want to see what Tripar’s engineering team can do to help your business? Challenge us to see what can be achieved!

Charity

Every year we donate a portion of our profit to a selection of charities. Last year we donated several thousand dollars to 10 charities including the Heart Foundation, Quebec Cancer Foundation and the Montreal Children’s Hospital. We will continue supporting these charities again this year, and are pleased to announce we have decided to also launch an internal Holiday food and toy drive this season!

Tripar employees are collecting food for ‘The Sun Youth Foundation’; a local organization helping lower income families in the community with emergency services and food aid, among many other great initiatives. We will also be collecting toys for children at the ‘Montreal Children’s Hospital’; a hospital that is near and dear to all of our hearts. We are eternally thankful for their excellent care and services and are happy to do what we can to bring a smile to those kids faces who remain patients over this holiday season.

If you would like any more information on either of these topics, please contact Connie Muro at Connie@TriparInc.com

Newsletter July 2017 ‘Prix-Estim’ Award

Award – ‘Prix Estim’

At this year’s 29th edition of the Eastern Montreal Chamber of Commerce Awards, Tripar was a finalist for a “Prix Estim” in two categories:

- Best Manufacturer

- Best Exporter

The award ceremony was a great evening, with many companies from Montreal coming together the celebrate their great innovation, success, and growth. Tripar ended the evening by winning the Best Exporter award due to our continued success within the USA and Europe, also running up in the Best Manufacturer category.

To see the full list of the winners, click here: http://www.ccemontreal.ca/estim/laureats-2017/

LightFair Philadelphia 2017

For the 14th straight year, Tripar exhibited at Lightfair International. Every year is always enjoyable at the show seeing new trends in the industry, but it is undoubtedly the face time we have with both old and new customers that we enjoyed the most.

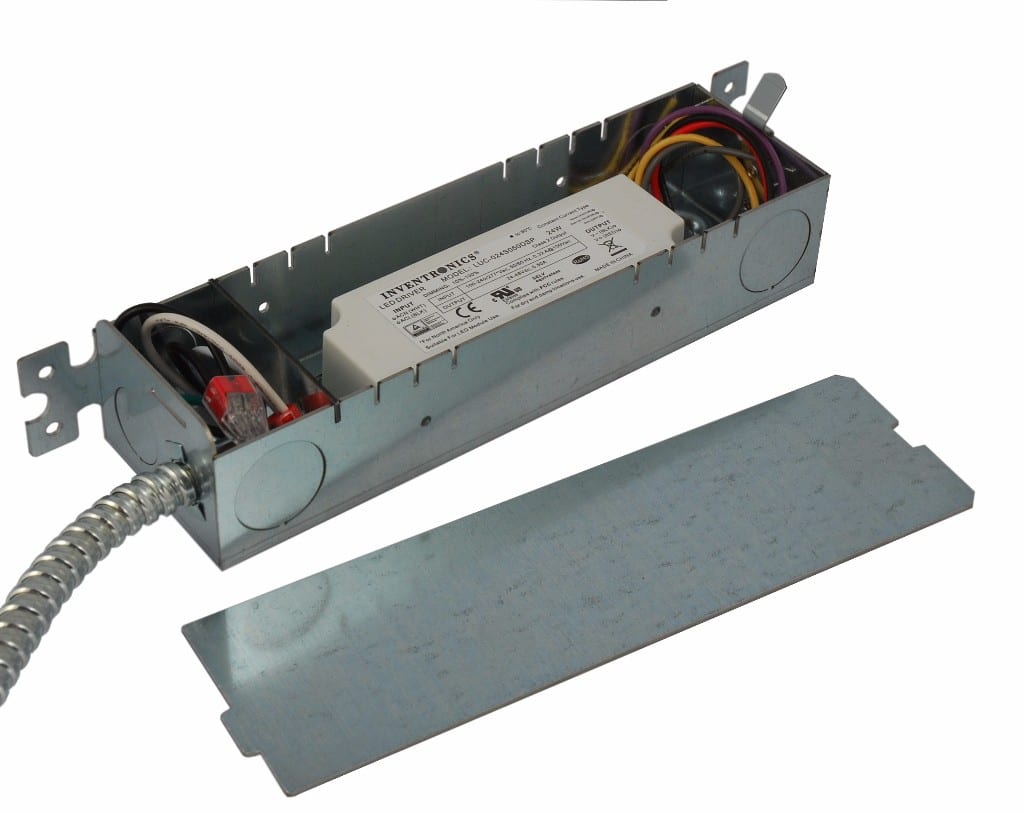

At the show we introduced our new line of universal driver/junction boxes, available in two sizes;

Small: W:2-3/8” x H:1-5/8″ Large: W: 4” x H:2”

Length: Choose any length from 8” to 120”!

Universal driver mounting – Array of slots, sized to accept #8-32 x ¼” long self-tapping screws (projecting feet on bottom conceal projecting mounting screws).Drivers mount in full contact with base of box for optimal heat dissipation.

Multiple knockout hole sizes at each end; 9/16”, 7/8” & 1-1/8”.

Multiple mounting options:

http://lighting.triparinc.com/wp-content/uploads/2017/05/NPB-Driver-J-box-April-2017.pdf

If you would like any more information on this new product, please contact Connie Muro at Connie@TriparInc.com