Introduction

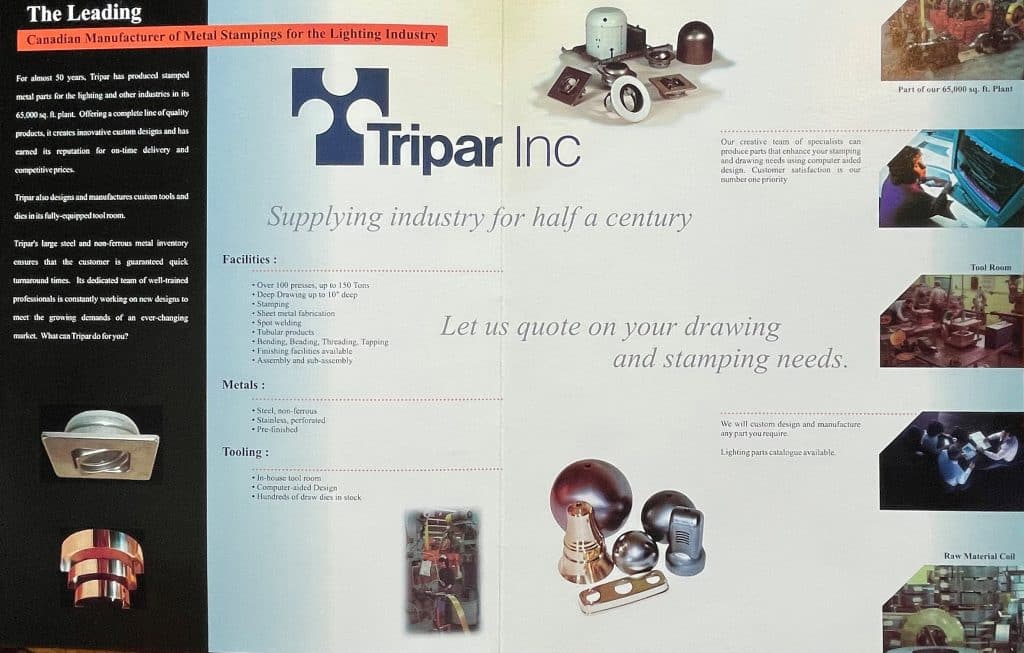

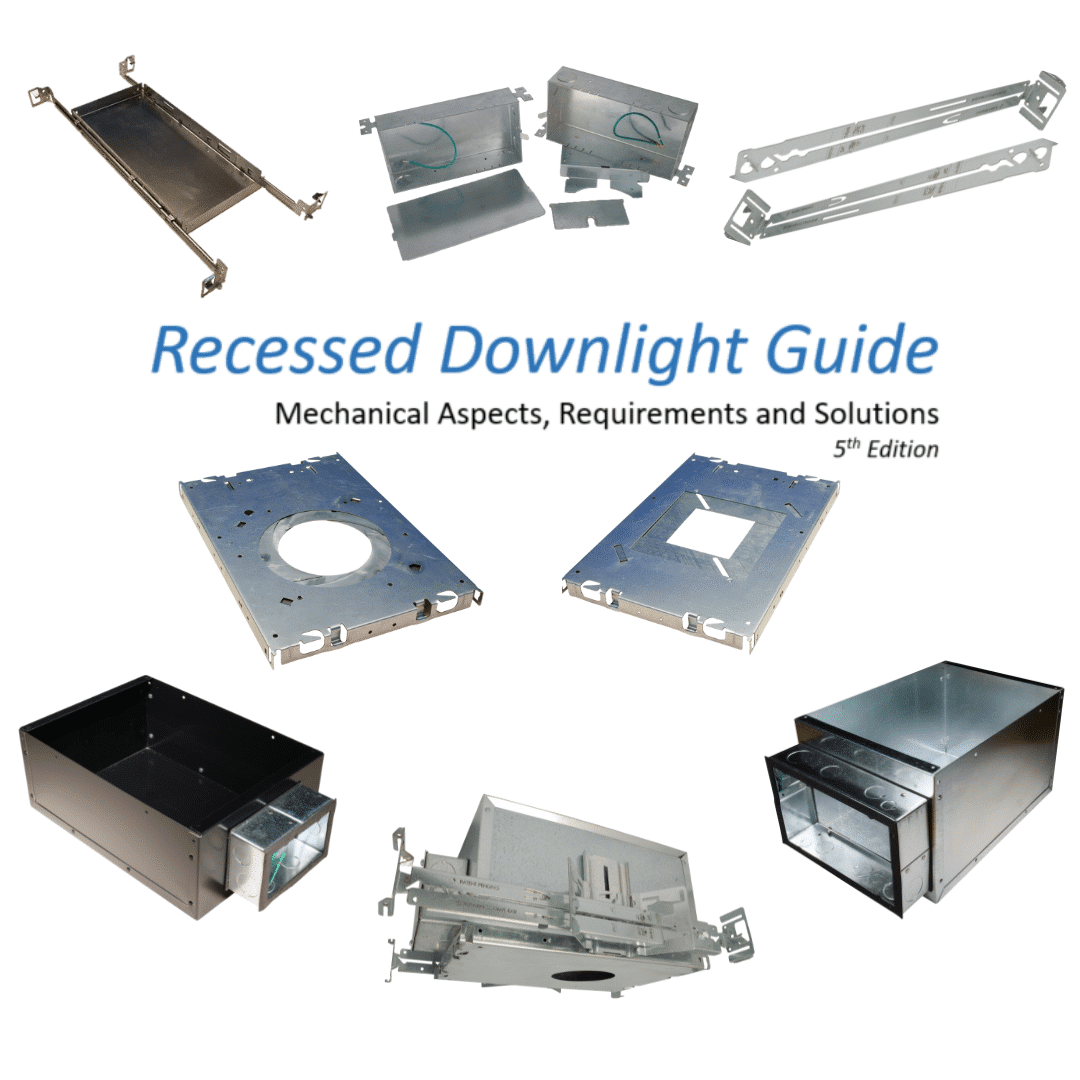

During the 80s, Tripar observed an increasing trend towards recessed lighting replacing demand for traditional decorative lighting components. To capitalize on this, Tripar developed its first line of standard recessed lighting parts. Like what we did for light fixture & lamp parts in the 60s and 70s, Tripar invested, developed and produced many tooling (dies) for the benefit of recessed lighting OEMs.

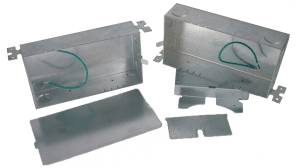

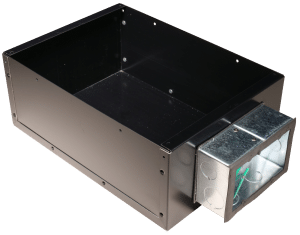

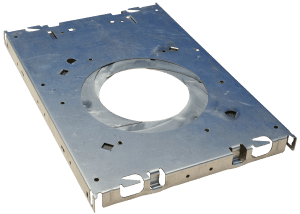

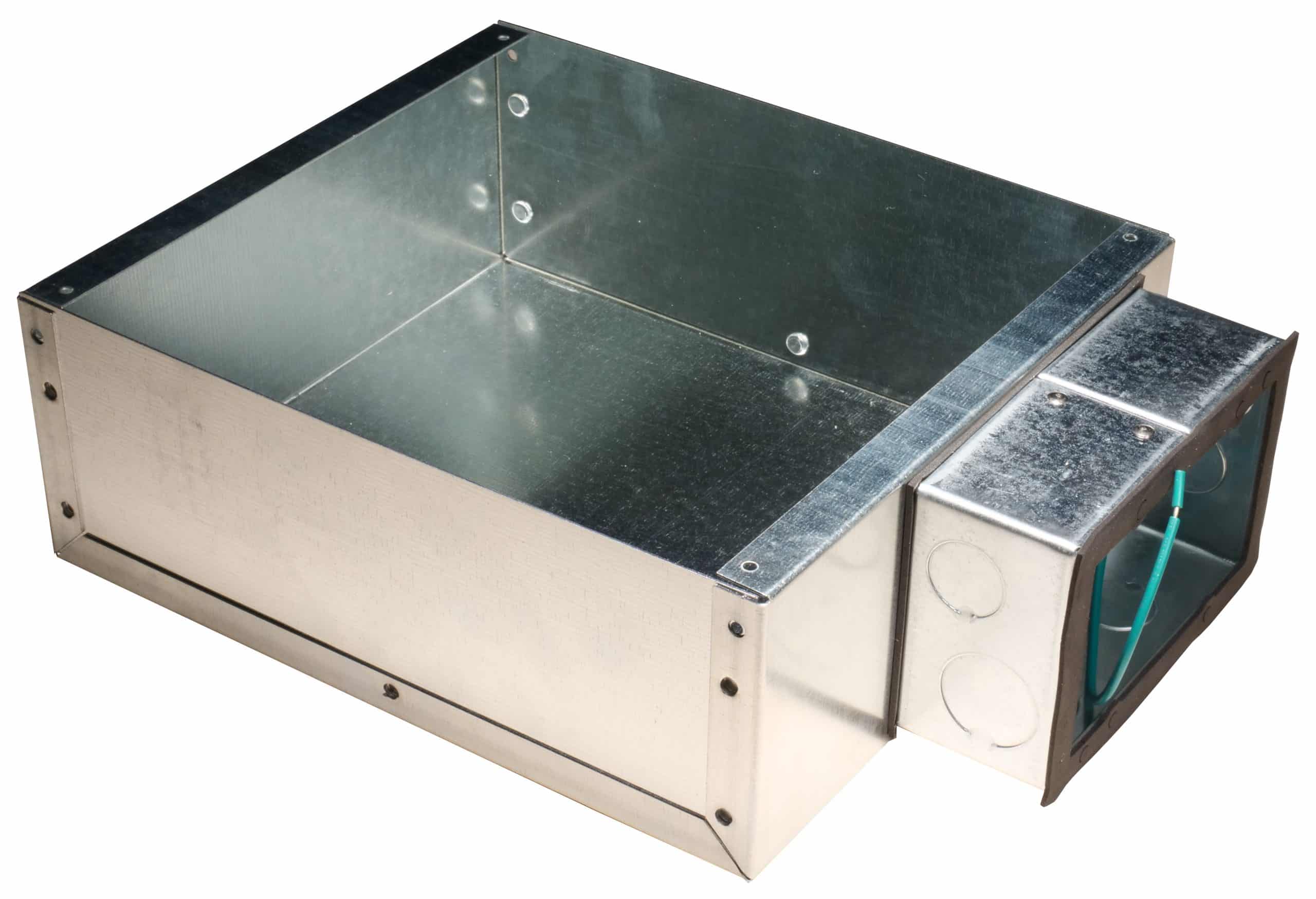

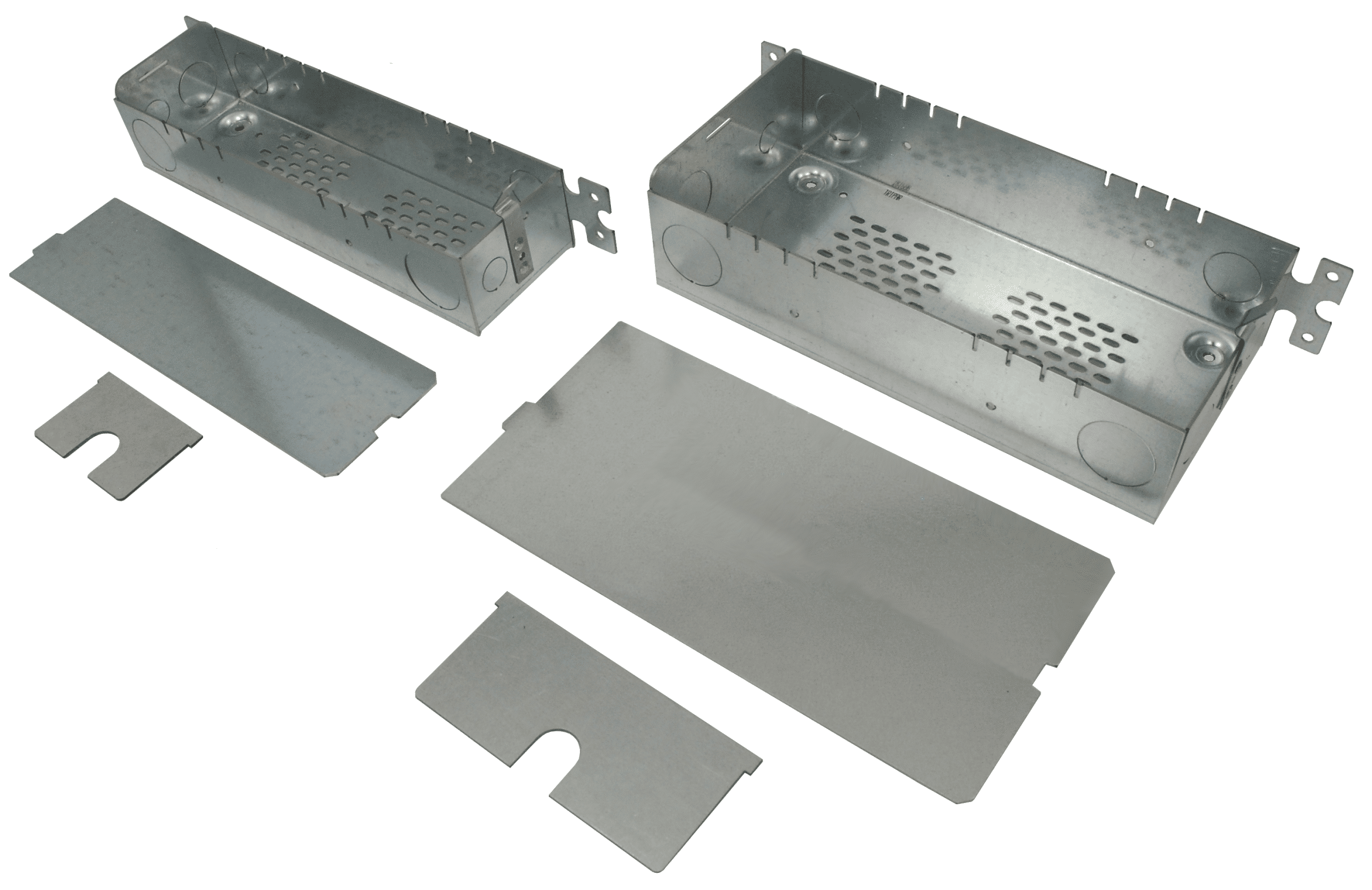

Sampling of recessed lighting parts from the 80s

Lloyd's personal path to engineering

In 1981, I graduated from Dawson College as a Mechanical Engineering Technologist. True to my plan, I applied to several university engineering programs, was offered placement in several, choosing the University of Western Ontario, located in London, Ontario.

I enjoyed living on my own for the first time, renting a house with three other students. Surprisingly, I did not enjoy most of my courses. Upon reflection, I think I had trouble going from the very practical technologist level program, to the very theoretical first year engineering program. I completed my first year, not quite successfully (having failed my course in Dynamics.) Very unsure what to do next, I decided it would not be to return to the University of Western Ontario, so I packed my belongings, returning to Montreal.

Though my plan was to get my university engineering degree, I was unsure at this point. So I enrolled for part-time studies in Concordia University in Montreal, to take the Dynamics course I had failed previously and to try working using my technologist status, but not at Tripar as my Dad always made it clear that I would not come to work here without having the benefit of working at least a few years in other companies to gain a broader experience base.

So during the summer of ’81, I quickly found work at Dominion Lock in Montreal as a Supervisor in their Key Blanking Department. At first, I enjoyed the challenges. But after a few months the lustre was lost for two reasons;

- The success (or failure) of my week was defined by the number of key blanks my department produced; over 1.5 million was a good week, anything less was not.

- I saw some opportunities for improvement and suggested some changes. To my surprise, the reply was always “Oh no, you can’t do that. That’s what the engineers do!”

Between these two, especially the latter which infuriated me (and having finally successfully completed the Dynamics course), I enrolled in Concordia University’s Mechanical Engineering Program in January ’82 with the attitude that I didn’t care if I learnt anything useful or not, but to obtain my engineering degree to open doors. Not a great attitude at the time, but it was what it was.

Upon entering Concordia’s mechanical engineering with a specialty in industrial engineering, I hit my stride, and was both enjoying the program and learning. I completed the program and earned my engineering degree in May ’85, “With Distinction”, having obtained a GPA of over 3.4.

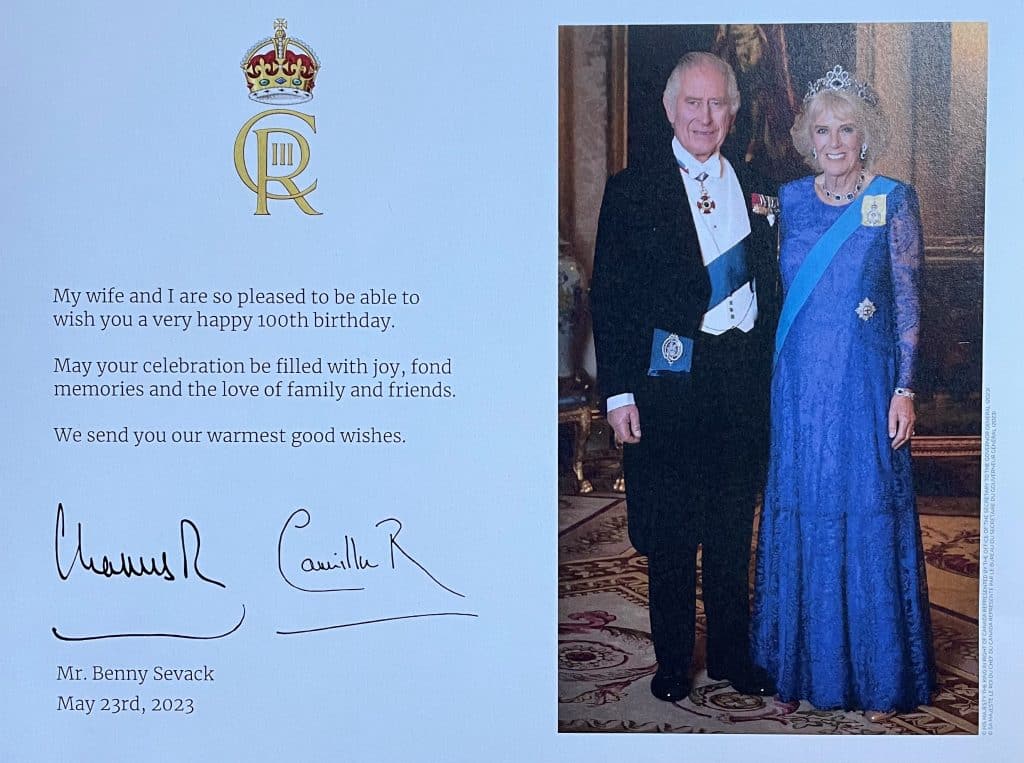

Lloyd’s graduation, circa 1985. From left to right: Lloyd’s Mom Eve, his Dad and founder of Tripar Ben, his bride to be Cheryl, and Lloyd

Engineering certificate from Concordia University

Working as an engineer

With my short work experience at Dominion Lock being too meagre to come work at Tripar, I applied for work at many companies, both in Quebec as well as Ontario. My first offer was for “Champion Truck Bodies”, a Montreal based truck body manufacturer. I accepted this, but before starting, received what I thought was a better position and offer from the Ernst Leitz (optics manufacturer and maker of Leica brand cameras) in Midland, Ontario, a small town located approx. 2 hours north of Toronto. So, I accepted this, and to the dismay of Champion, I retracted my offer there.

Getting set to move to Midland with my new wife Cheryl, a week before I was to start work at Leitz, the phone rang. It was yet another company I applied to earlier, “Computing Devices Co” (CDC), a defense electronics contractor, offering me an interview. I explained my situation to the Director of Human Resources and the pending start at another company, saying that the interview would have to be scheduled quickly, as in, the next day! Obtaining this, with CDC being in Ottawa, an easy 2-hour drive from Montreal, and with nothing to lose, I went for the interview there.

The interview was for the position of Product Engineer, to be the technical liaison for one of CDC’s contract manufacturing operations, in this case between CDC and Hughes Aircraft. At the end of the interview, they said they would let me know. At that point I had little choice but to explain to the Director of Engineering my acceptance of another job offer, which was to begin the following Monday, so he would pretty well have to let me know right away if he was interested. He asked if I had another hour or so, which I did, so he told me to wait in an office and shut the door, leaving me alone. Less than an hour later he returned with a job offer!

So back I drove to Montreal to explain the latest to Cheryl. With Leitz being in Miland, a beautiful but very small town, should it not work out for any reason, there were not too many other industries in which to find alternative work. By contrast, with CDC being in Ottawa, a much larger city, we decided to accept CDC’s offer. And so I had to back out of my second acceptance (Leitz)! I accepted CDC’s offer, we quickly moved, and I began working there In Jan ’86.