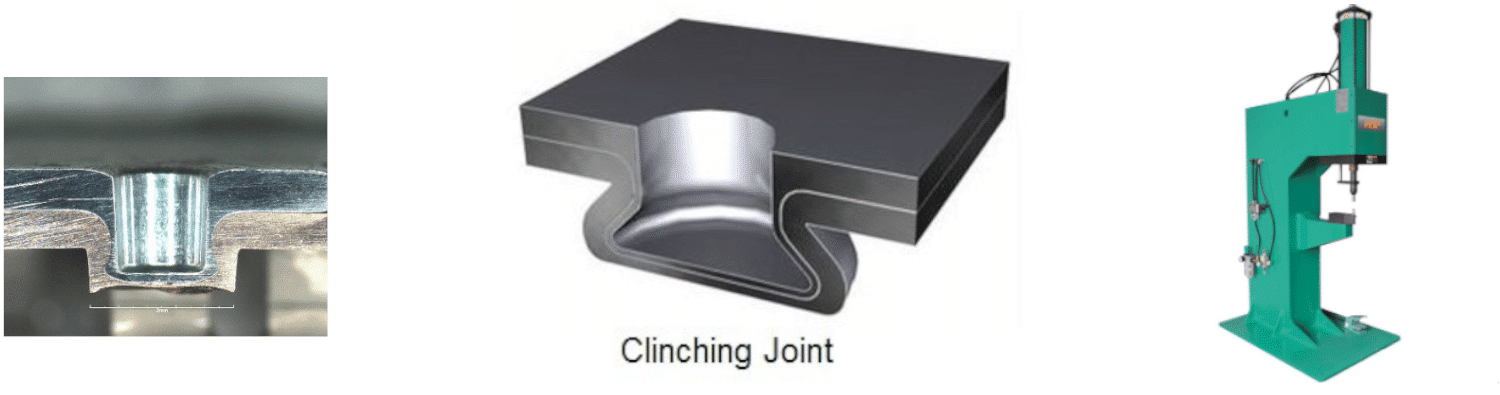

This TriparTech gives an overview, plus advantages and disadvantages of Clinch Joining, which is a process used to join two pieces of sheet metal sheet together without any fasteners.

Continue readingNewsletter January 2019 70th Anniversary

Tripar 70th Anniversary

1949-2019: Tripar, your trusted partner for 70 years and counting…

2019 marks Tripar’s 70th anniversary! Lloyd Sevack, President has written an open letter to mark the milestone.

To all our valued customers,

When can a company be called a legacy? If longevity and reputation are two measures, I think that Tripar can claim such status. Having been founded in 1949 by my uncle, David, and my Dad, Ben Sevack, my entry into the business in 2001, and the third-generation present, with my daughter, Lauren, Director of Human Resources, this year, 2019, marks our 70th anniversary!

Much has changed since Tripar’s founding, from a rented space with 3 employees and a few presses….Please click here to continue reading the full letter.

Canadian Fabrication and Welding Article

Tripar is featured in the latest (February, 2019) issue of Canadian Fabrication and Welding magazine. Click here to read more about all that Tripar offers, including some of our evolution, challenges, and how we are meeting them. Please click here.

Case Study: L-Bars™

Several of Tripar’s customers asked for a more robust bar hanger solution than its current and hugely popular 1287 bar hangers, all looking for a bar hanger more suitable for commercial applications.

Continue reading70th Anniversary

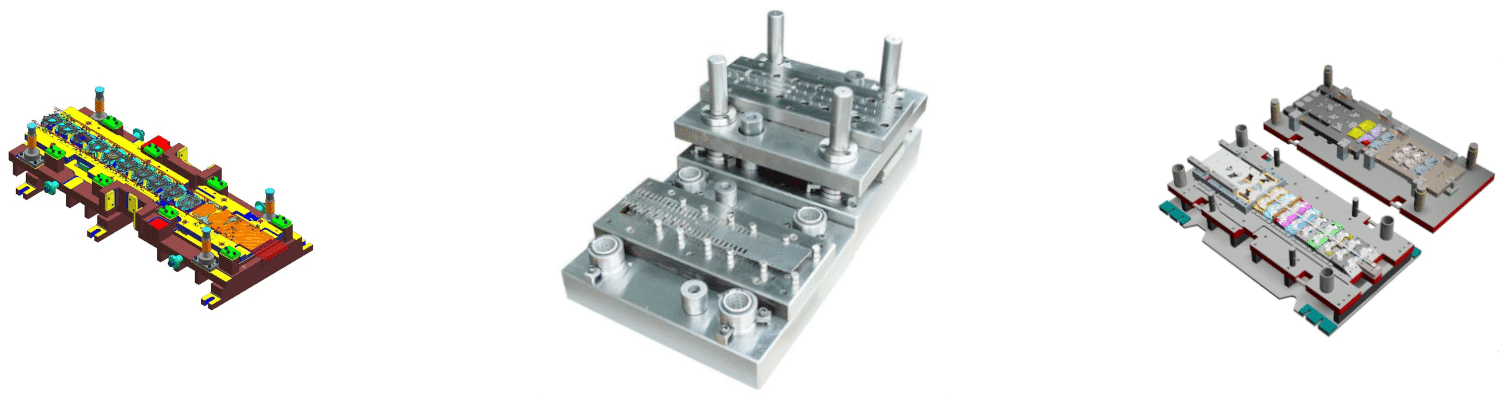

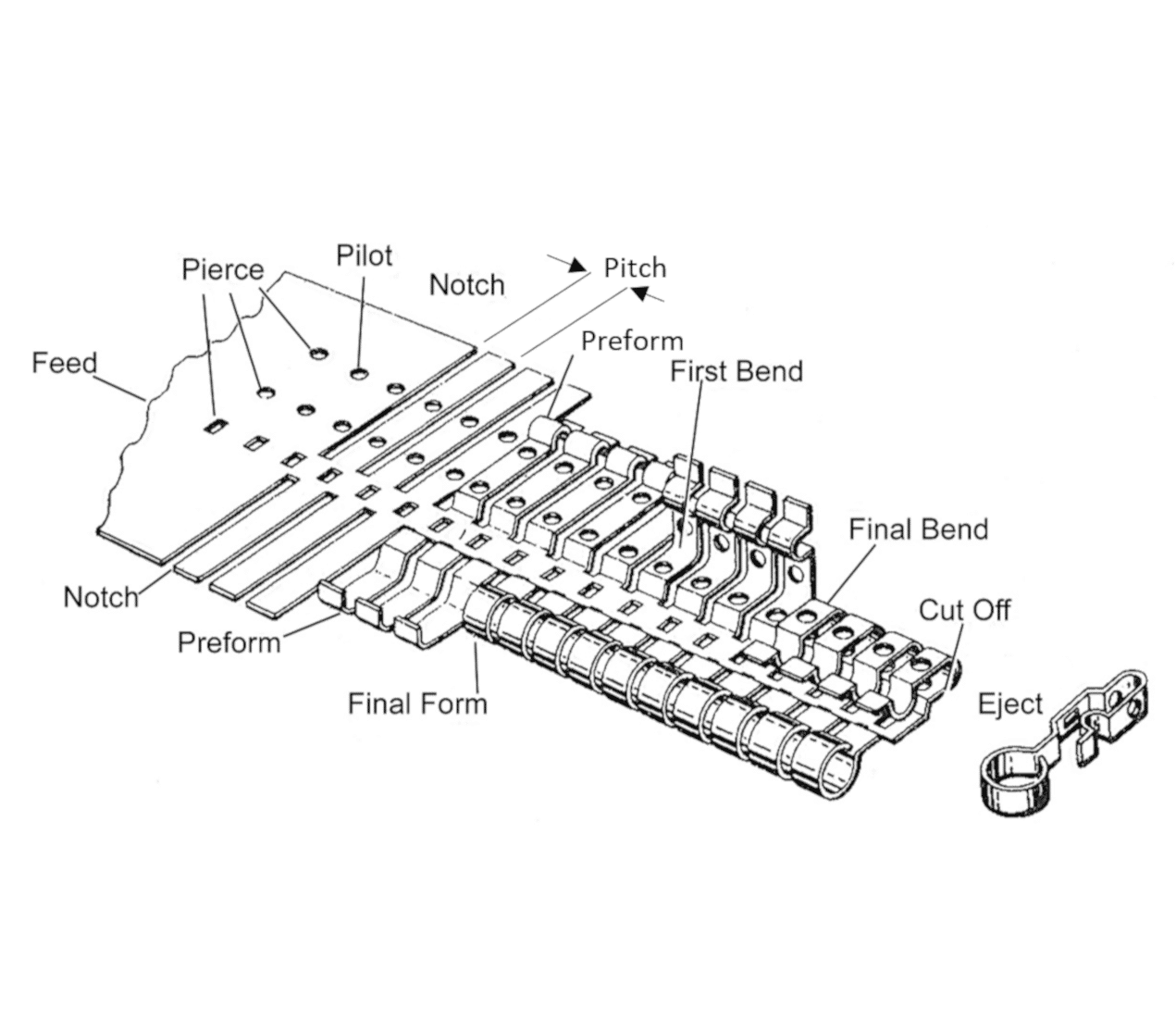

TriparTech: Progressive Dies & Progressive Die Stamping

This TriparTech provides an overview of progressive die stamping, which is a sheet metal forming process widely used to produce parts for a variety of industries

Continue readingNewsletter October 2018 Tripar Tech

TriparTech

We are pleased to launch “TriparTech”; a new series of technical bulletins.

These will be published every 1-2 months, each covering a technical subject that we are certain you will be able to benefit from; be it for design, manufacturing, material, or cost related reasons. These are drawn from Tripar’s engineering knowledge and manufacturing experience in a wide range of manufacturing processes.

The first TriparTech bulletin is entitled: Progressive Dies and Progressive Die Stamping, providing an overview of the process, the financial considerations, alternatives, a video showing the process, and conclusions. Please click here for this first TriparTech.

Stocked Items

Tripar manufacture and stock a range of over 30 different Lighting components for OEM’s. These include Plaster frames, Junction boxes, I.C. Boxes, Brackets, and Bar Hangers. To view the full list of stocked items available, including the release quantities based on complete box sizes (and full skid or pallet), please click here.

The benefits of utilizing these stocked items include:

- High quality stamped components benefiting from economies of scale

- 48hr Lead time (for complete box quantities and multiples of box quantities)

- Feature packed components that can only be achieved when stamped

- All components designed to fit together for complete assembly or used separately in own fixture

- All designed to meet UL1598 regulations

If you are unable to attend the show and would like any more information, please contact Connie Muro at Connie@triparinc.com.

CNC Laser/Punch Combo

Tripar has expanded its metal fabrication capabilities over the years with a CNC laser, several CNC Press Breaks, and just last year a brand new CNC Punch/Laser Combination Machine. This incredibly versatile machine often permits the complete processing of workpieces, since many features can be achieved in a single operation; not only punching & laser cutting, but also tapping, forming, bending, extruding, marking of components, and more!

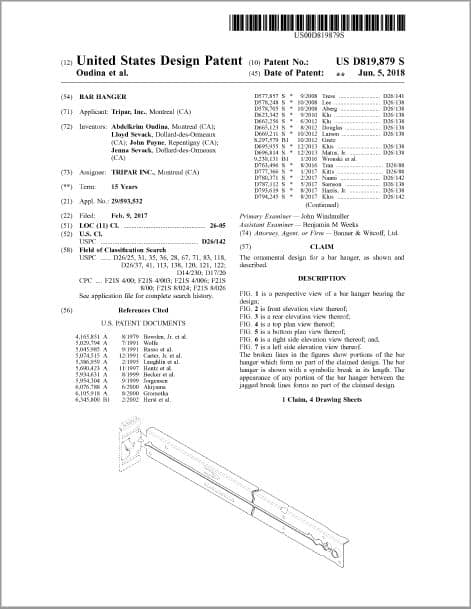

8th US Patent

Newsletter April 2018 Lightfair Chicago

Lightfair Chicago 2018

May 8th – 10th Tripar will be exhibiting at Lightfair International for the 15th straight year. This year in Philadelphia, Tripar will be on Bill Brown Sales/ALP Lighting’s Booth #2019. Every year is always enjoyable at the show seeing new trends in the industry, but undoubtedly it is the face to face time we have with both old and new customers that we look forward to the most.

In 2018 Lightfair continues the paperless On-line VIP Pass Program which we invite you to take advantage of. Simply click on the link, copy the code (V24878), and register online for your VIP Pass.

Your VIP Pass Code is: V24878, please click here to register.

Be sure to visit us at Booth Number: 2019

New Capabilities

Tripar continually strives to employ the best practices so that we can offer our clients optimal quality, design assistance, manufacturing, and delivery, all at competitive prices to allow OEM’s the best chances to succeed in highly competitive markets.

Tripar has just become the first company in Canada to purchase this brand-new machine, propelling our capabilities to the forefront of the industry! This unique combination allows Tripar to manufacture a range of highly complex components, from prototypes & small quantity runs, to mass production of multimillion pieces per year.

Please come and visit us at Lightfair to see what machine we bought and how it can help you produce higher quality and more cost-effective components.

If you are unable to attend the show and would like any more information, please contact Connie Muro at Connie@triparinc.com.

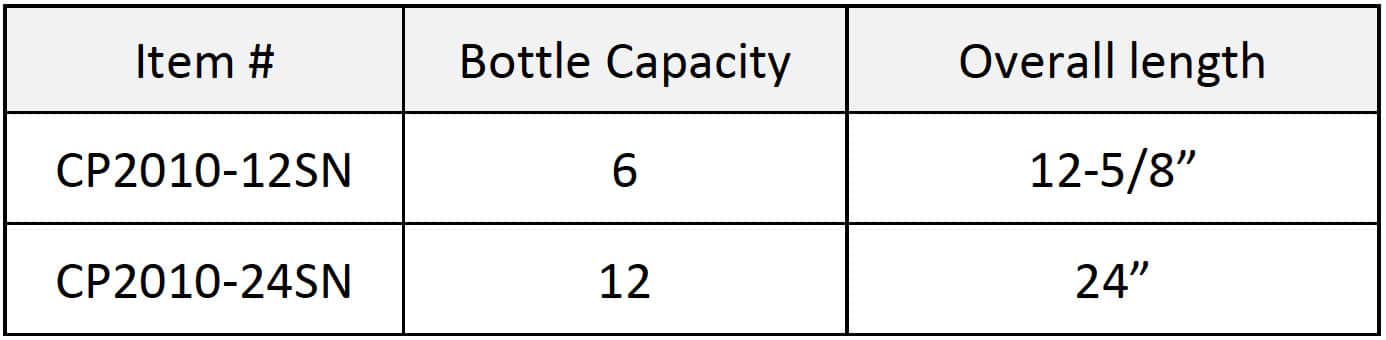

Wine Rack

This wine rack is as functional and compact, as it is aesthetic, with no visible means of support!

The neck of each bottle is inserted into opposite sides of this vertically mounted rack, allowing the horizontally suspended bottles to be rotated so the labels are visible.

The hole size has been optimized to accept well over 95% of standard wine bottle necks; large enough to hold the overwhelming majority of bottles, but still with minimal sag. The few that may not fit are champagne bottles which have a larger upper neck or finish, and a few odd “designer” bottles.

With two rear flanges containing mounting holes that are accessible only through the wine bottle holes, the fixing screws remain hidden for an exceptionally clean look.

CP2010-12SN

CP2010-24SN

Formed to 2” wide x 3-3/8” deep, and made from a brushed satin nickel steel that has a clear topcoat, these racks never need polishing.

Offered in two sizes/capacities:

To obtain more information about these products contact our sales team Sales@TriparInc.com

To obtain more information please contact our Sales Team at Sales@TriparInc.com.