This series continues with the second decade. Tripar quickly outgrew its first premises and then moved in the east end of Montreal, where their first owned plant was erected.

Continue readingTrapezoid Airtight IC Boxes

Save over 50% on shipping costs with these new stackable Trapezoid IC boxes

Continue readingKnockouts 101

This TriparTech provides an overview of knockout requirements in luminaires, which are governed by UL1598, Standard for Safety for Luminaires.

Continue readingSheet Metal Fasteners

This TriparTech on other sheet metal joining options called Fasteners.

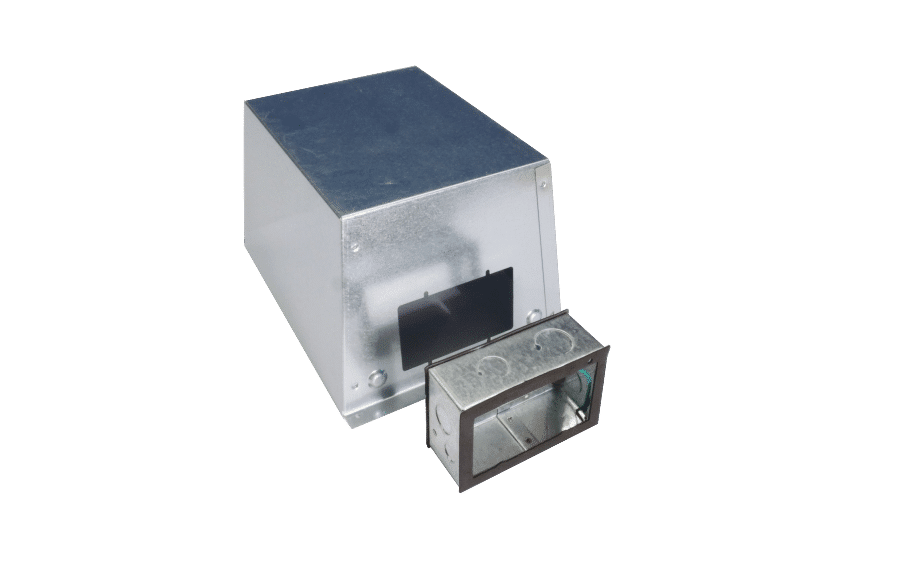

Continue readingIC Boxes w/ Junction Box 70

We are pleased to introduce a new line of IC Boxes, the same as our proven Single Ceiling IC Boxes, but containing a much larger junction box (J-Box), measuring 7-7/8” long x 4-7/8” tall x 1-7/8” deep; approx. 70 cu.in. hence the “70” in the description.

Continue readingTriparTech: Galvanized & Galvannealed Steel 101

This TriparTech provides the benefits and limitations of these of Galvanized & Galvanneal Steel, both are commonly available in sheet or coil form in a variety of thicknesses.

Continue readingNewsletter September 2020 – Tripar New Slogan, Mission & Vision

Over the last few years there have been many changes in technology, industry, our capabilities & personnel, and now worldwide with Covid-19.

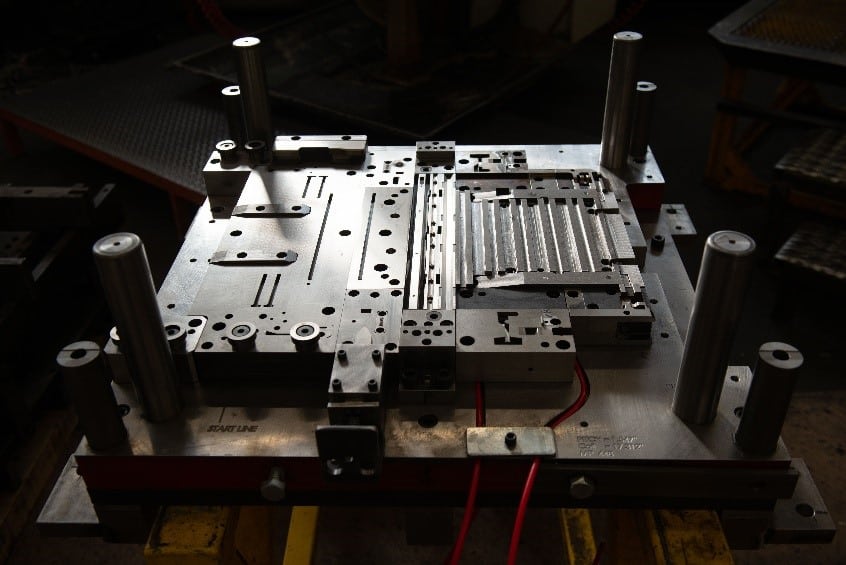

Continue readingTriparTech: Hybrid Manufacturing, Options to Metal Fabrication vs Metal Stamping

Sheet Metal fabricated parts can be produced by many processes. The two broad methods are metal stamping and metal fabrication. To understand where each comes into play, you must first understand what each is, and what the differences are.

Continue readingTriparTech: Design for Manufacturability, Part 2

After publishing “Design for Manufacturability, Part I: Tolerance Tolerant Design” in October 2019, Tripar is pleased to publish a follow on to this with “Design for Manufacturability, Part II: Feature Design”.

Continue readingDeep Drawn Aluminum Cylinders

A Tripar customer had been buying a deep spun aluminum cylinder (5” diameter, up to 11” long, closed at one end) for approx. $10-$14 each.

Continue reading