Introduction

As continued sales growth resulted in the need for additional space, in 1972, Tripar had a third expansion of 12,000 square feet bringing its new total to 45,000 square feet.

The decade of exporting: United States & United Kingdom

The 70s was also the decade that Tripar begin exporting on two fronts; principally by securing distributors in both the US and the UK;

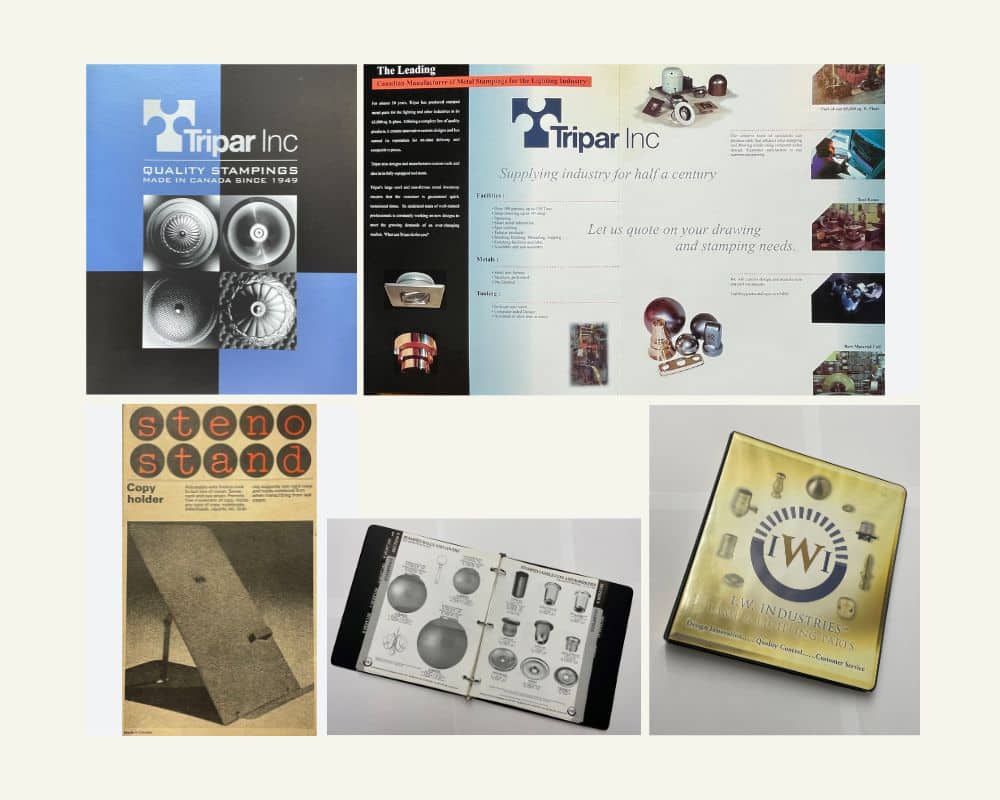

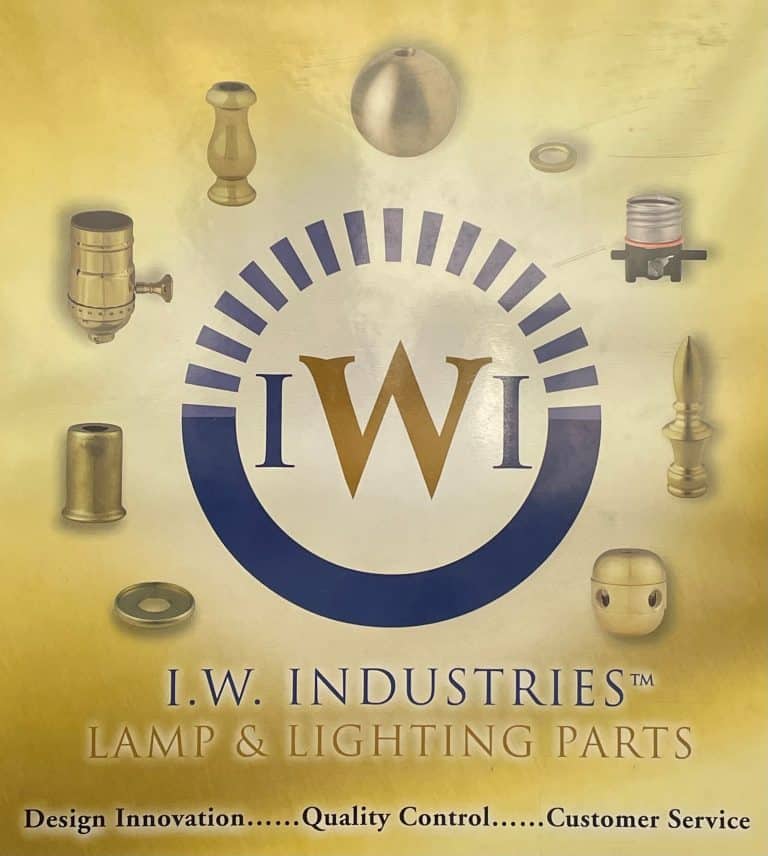

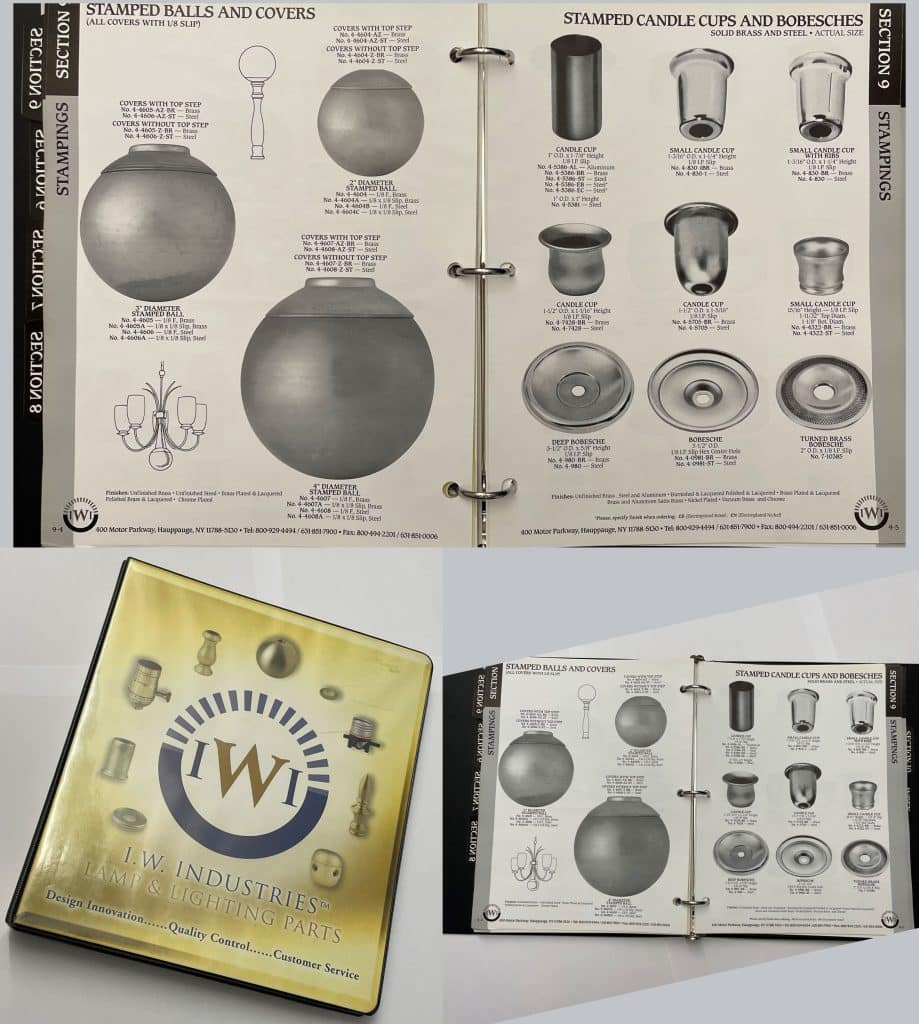

US: Tripar secured IW Industries as its distributor, located in Melville, New York. Murray Cohen at IW was responsible for adding much of Tripar’s light & lamp parts to its own catalogue.

IW Catalogue 50+ pages worth of Tripar parts

IW catalog showcasing Tripar lighting parts

Having IW as Tripar’s distributor allowed penetration into the US, with IW buying relatively large quantities of many of Tripar’s parts, stocking them in the US, for resale to smaller US light fixture & lamp OEMs. In fact, of IW’s 191 page catalogue, 57 were devoted to stampings; the overwhelming majority made by Tripar. In fact, IW used Tripar’s part numbers for these, but simply added a “4-“ prefix to designate Tripar as supplier #4.

UK: Tripar secured Duba, owned by Philip Frush as its UK distributor, following the same practices and purpose as IW’s. The only difference was shipping costs, which unlike affordable and frequent truck shipments to IW in New York, air shipments to the UK were prohibitive, so periodic consolidation of sufficient orders into a full container was the only, but workable solution.

During this decade, Tripar also ventured into developing two new products outside of lighting;

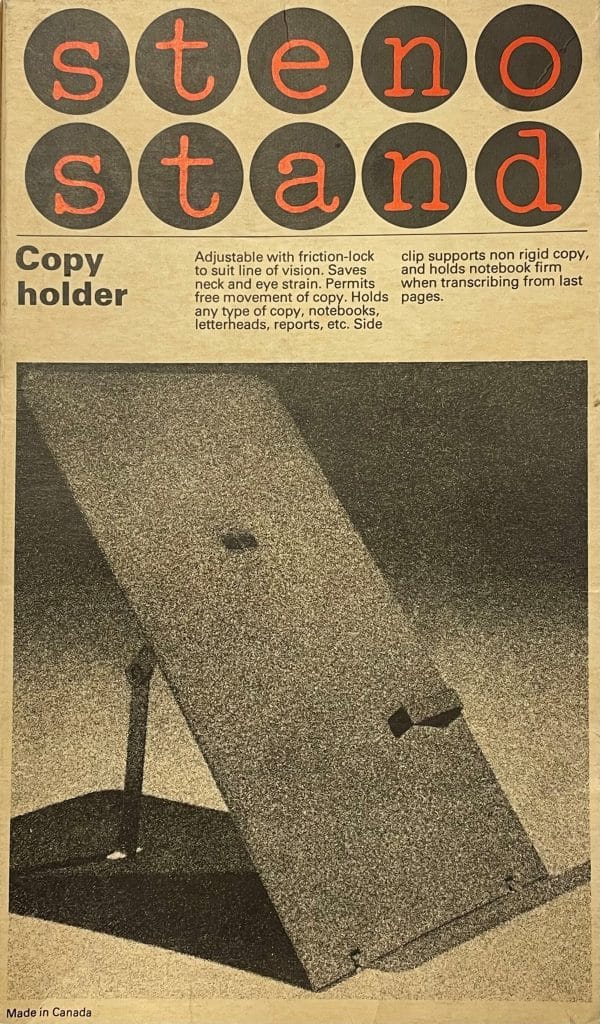

1. Steno Stand: This was a foldable and Adjustable stand for holding loose sheets upright at whatever angle the “typist” chose, to transcribe what was written on the sheets onto her typewriter (not to be sexist, but that’s how it was in the 70s!).

Steno Stand

Steno Stand used for Transcribing Notes

2. Ashtray: With smoking being way more prevalent and accepted than today, Tripar sold not only ashtray parts, but also developed its own. This was based on using one of its deep drawn balls (approx. 3” diameter), tipping the opening on its side, spot welding a base to prevent the ball from rolling, and adding a trap door with a small snout at the front. When the trap door was open it would rest level, leaving the small snout to rest the cigarette on, and the ashes to fall onto. When done, the trap door would be flipped up, allowing the ashes and butts to fall into the ball. These were of course available in gaudy bright colours that were in vogue in the 70s; orange, lime green, and purple to name a few. Back then, it was not uncommon to see press operators at Tripar smoking at their machines, with these ashtrays resting on the press table.

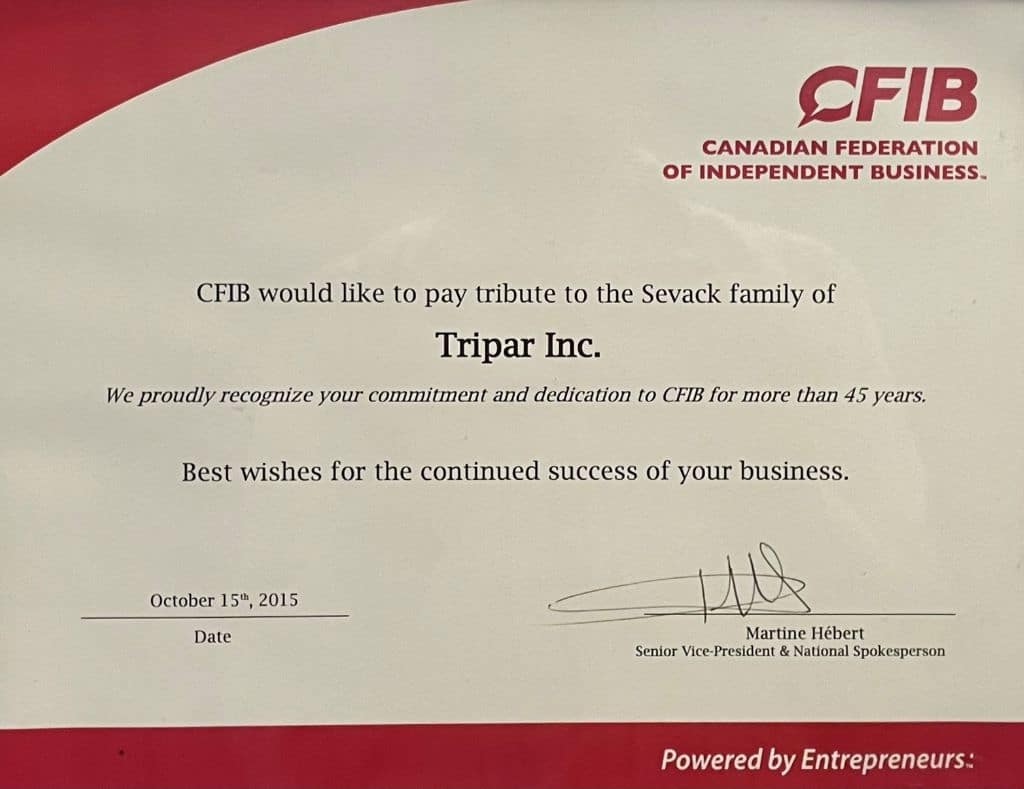

Tripar’s CFIB Membership

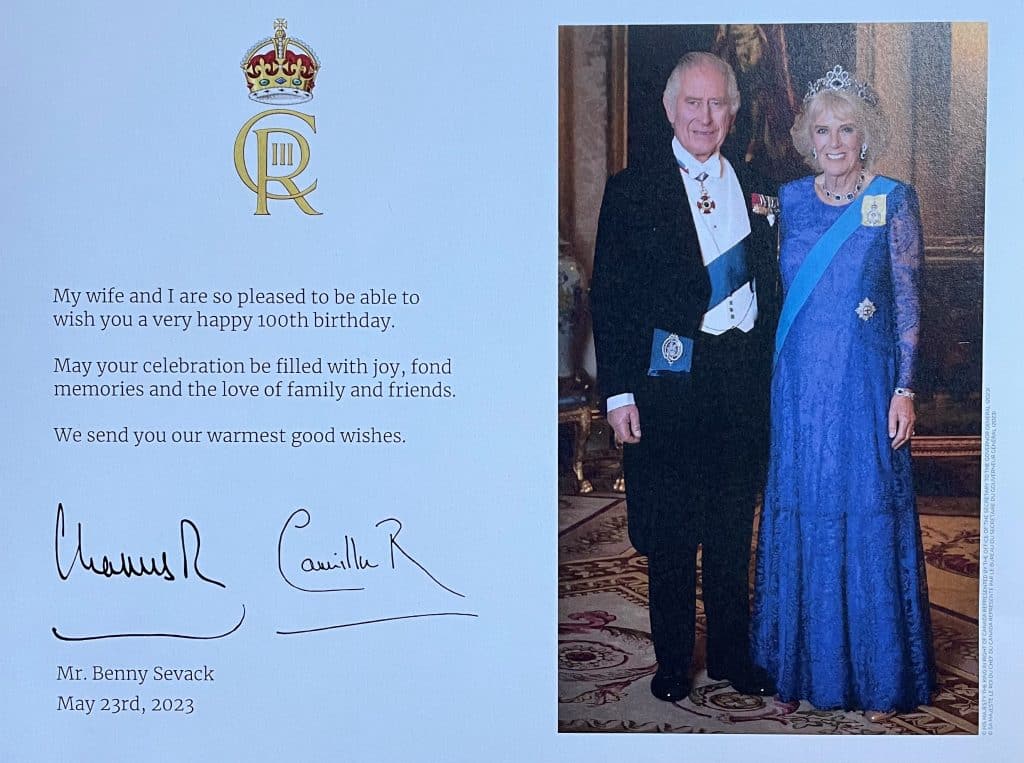

Unrelated to Tripar but most certainly an important moment for founder Ben during this time, was his discovery of the upstart Canadian Federation of Independent Business (CFIB) whom Tripar has been a member of for over 50 years now, and whose membership goes 1 additional year prior to its existence! How is this possible?

The way the story goes, my Dad was reading the newspaper in the bathtub, and was energized by an article on the business taxation polices of the Canadian government, written by someone by the name of John Bulloch. My Dad tracked John down and wrote him a letter, sympathizing with some of his views, asking if/how he could help. This led to John creating the CFIB, a non-profit federation to both help small business navigate government red tape, as well as lobby governments for policies that would help small businesses thrive, (and ultimately employ more people with their success, which would in turn help the government in terms of revenue generated from personal income taxes). So, Tripar is credited with having joined the CFIB one year before its creation! Ben was also on the CFIB’s Board of Directors for many years, and has remained a founding member, or rather since 1 year before its official founding.

Lloyd learning the family business

The late 70s is when I graduated from high school, 1978 to be exact. Being fortunate to know what I wanted to be when I “grew up” (besides an astronaut or race car driver), was a Mechanical Engineer. The usual path for this was to go to CEGEP (Quebec’s college program) in Pure & Applied Sciences for 2 years, which was the precursor to permit entry into many science & engineering university programs. Knowing before this that becoming a Mechanical Engineer was my ultimate aim, I decided to take a 3-year CEGEP program to first become a Mechanical Engineering Technologist. Though this would add an extra year to my studies, I felt having earlier and targeted mechanical engineering related courses would be of greater benefit in the end.

This of course allowed me to be more “useful” to Tripar. So part-time during my studies, as well as during the summer holidays, I began to work in the maintenance department. With the work there being much less repetitive, it was both more interesting, as well as giving me the opportunity to learn things such as welding & machining, and eventually to the toolroom, where I learned much about dies and toolmaking.

1979 was not only Tripar’s 30th anniversary but also the year of its fourth expansion, adding 22,500 square feet, and bringing its new footprint to 67,500 square feet.